Perhaps, all gardeners know that it is just impossible to do without a shower at the site. This is especially important in the summer, when, after a day of work on the beds, it is necessary to take water procedures simply for reasons of hygiene.

It is easy to assemble a summer shower, and there are a great many manufacturing options. On some aspects of the work and will be discussed further.

Screen

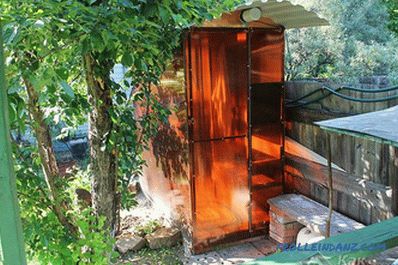

Shower-screen

Shower-screen

As a temporary solution you can make the simplest shower: at a certain elevation, fasten a metal or plastic tank, preferably of a dark color, with a tap and a mixer, to make a folding screen. For everything about everything, the minimum amount of materials, time and labor will be needed, so such a structure can be built in a few minutes.

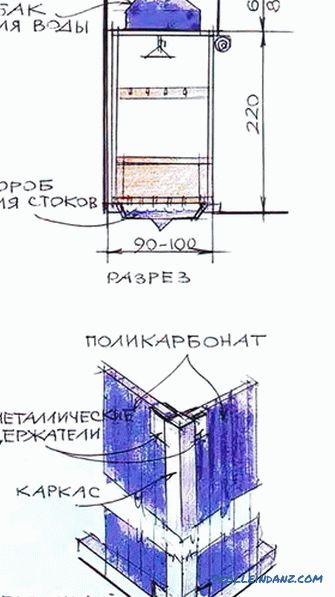

Polycarbonate shower

Polycarbonate

Polycarbonate

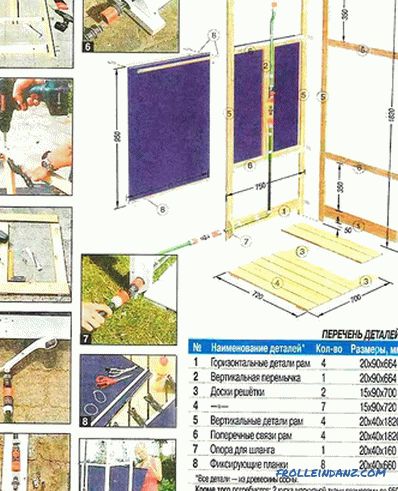

Work steps:

- First, align the place where construction is assumed.

- Then you need to mark the place. A wooden peg is driven into the ground. Then, at a distance of about two meters from it, the next one is driven in and the cord is pulled between them.

- Similarly, two more pegs are driven in and connected, so that a square is formed. To check the correctness of the markup they compare the diagonals, they must match.

- At the corners of the markings it is necessary to dig holes about 1 meter deep.

- Wooden or metal poles are installed in these pits. It is important to remember that the part of the pillar that will be below ground level should be treated with waterproofing materials, for example, wrapped with roofing felt. As a sealer, necessary for the strong retention of the pillar in the ground, you can use a brick battle or concrete, if we are talking about a metal frame.

- Then you need to crate the structure. At a distance of about one meter from each other, boards are nailed or screwed with self-tapping screws, or metal profiles are welded. This crate must be made over the entire area of the walls. Where there is a door, the crate is not made.

- Then, polycarbonate sheets are mounted on the walls. The sheet is cut to size and screwed with screws.

- The next stage of construction is the installation of the roof. As a roofing material can be used, for example, simple slate. Pre-stack and fix several horizontal bars, which will perform the functions of the truss system. Sheets of slate are laid and fixed on them. It should be borne in mind that on one of the sides, small bars should be placed under the bearing bar in order to provide the angle of slope necessary for the precipitation to flow.

- Next, a water tank is installed. In the place of its installation it is necessary to additionally strengthen the overlap. The tank can be made, in principle, of any material, but plastic should be preferred. This tank will be much lighter than metal, which is important.

- And finally, the final step is the installation of the door: a wooden frame of suitable size is sheathed with polycarbonate and mounted on hinges.

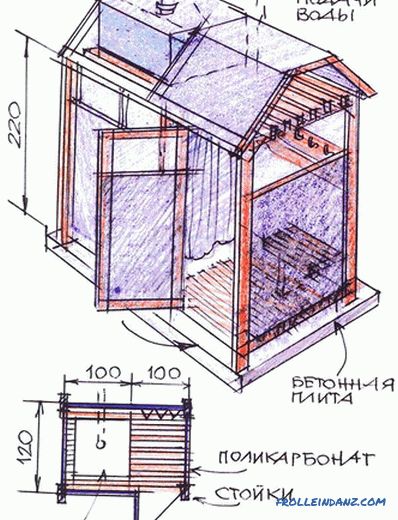

Scheme

Scheme

You can use a simple pallet as the floor the lattice made of a wooden bar.

Shower enclosure on metal frame

on metal frame

on metal frame

For the manufacture of shower, you can use a metal corner.

- First, the frame is welded. Its dimensions are chosen arbitrarily, but the height of the building must be at least 2 meters.

- After the frame has been fabricated and installed, a water tank is mounted upstairs, and some opaque film stretched between the supports will serve as walls.

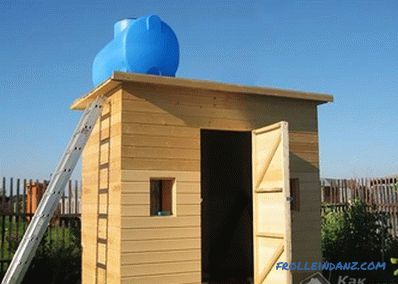

On the Foundation

On the Foundation

In order to shower one person, you will need at least 20 liters of water, which means that even the smallest water tank should have a capacity of about 50 liters. It follows that the installation site of this tank should be well strengthened.

Video: building a summer shower on a metal frame with a barrel of 220 l

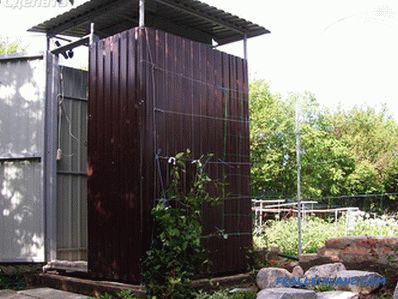

From a metal profile

Among the materials, we can mention the metal profile that has become customary. As in the previous case, the frame is built, and then sheathed with this material. In principle, this option deserves attention, but on the practical side, metal is not the best choice.

Constant contact with water will take place in the shower, which means that no matter how well the profile sheet is covered with protective compounds, corrosion will begin rather quickly.

Again, as a temporary measure, you can quickly resolve the issue. With all the necessary materials for the construction of such a structure is assembled in just a few hours. But perhaps this is one of the few advantages.

Video: Summer shower design from metal profile

Heated

Shower tank

Shower tank

This option is good for all indicators, as it allows you to use the shower in any weather, however, its device is somewhat more complicated and requires great knowledge and skills.

- You need to make a solid foundation and use logs or metal.

- The most acceptable base option would be a kind of monolithic plate. It is necessary to dig a small ditch about 70 cm deep. At the bottom, a pad of sand and gravel is poured in succession. The thickness of each layer is 20 cm.

- There is a concrete screed on top of this cushion.

- Then the soul frame is mounted. Acene tubes treated with water-repellent compositions can be used as the base for the frame.

-

Sheathed with clapboard The external walls of the shower should be finished, for example, with wooden clapboard. To do this, first going to crates.

Sheathed with clapboard The external walls of the shower should be finished, for example, with wooden clapboard. To do this, first going to crates. - Inside the walls are sheathed with insulation and waterproofing, and then also finished with clapboard.

- Then you need to make a truss system of wooden beams. After that the crate is mounted, which is covered with roofing material. As such, you can, for example, use metal profiles.

- Next, a door is installed.

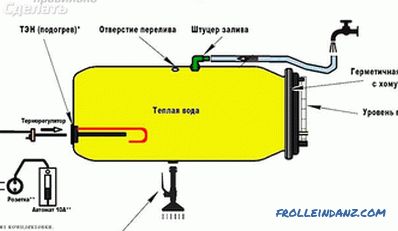

- Finally, the water tank and the heating system are directly mounted. The most acceptable and simple option is to purchase a special system with automatic temperature control. As soon as the water temperature drops to the set point, the relay is activated and the heating is activated. When using such a system, the shower can be used in any weather and temperature, which is very convenient. However, please note that for the heating operation will require the availability of electrical network.

Capital shower

Capital shower

It can be added that one of the most important conditions for the work of such a soul is device reliable insulation. As the most suitable for this material can be called polystyrene foam. It is resistant to moisture and easy to install. And if it is also covered with a dense film, then you will get an almost hermetic room, which will be relatively warm in itself.

To speed up the heating of water in the tank, it can be painted black.

Barrel-tank with heating

Barrel-tank with heating

If a heated system is used, it can be additionally equipped with an automatic water, than even more to facilitate their lives, but all these technical devices will entail additional financial investments.

Out of scrap materials

Out of scrap materials

Photos

Summer of wood

Summer of wood

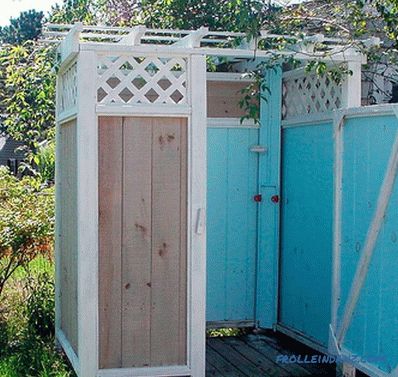

Beautiful summer version

Beautiful summer version

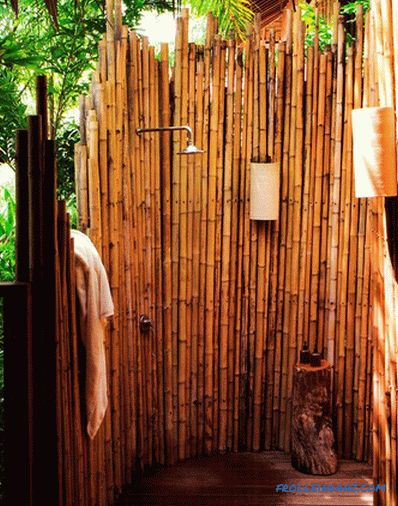

Bamboo

Bamboo

At the cottage

At the cottage

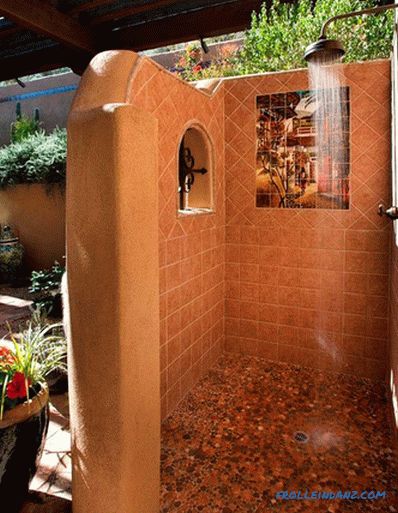

Tiled

Tiled

С a pallet

С a pallet

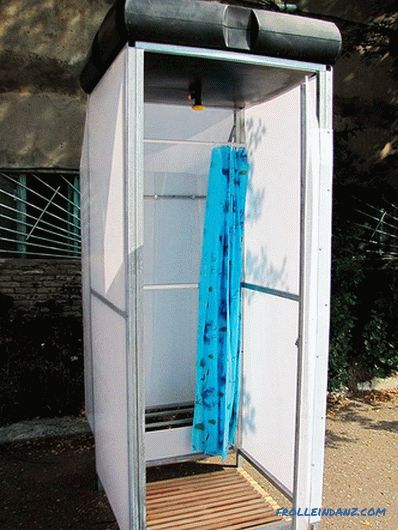

With curtains

With curtains

From profiled

From profiled

As an extension to the house

As an extension to the house

With a shed roof

With a shed roof

With a flat barrel

With a flat barrel

Homemade shower

Homemade shower

Drawings

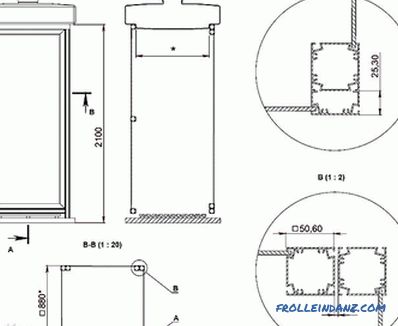

Soul drawing

Soul drawing

Photo-drawing

Photo-drawing

Summer option

Summer option

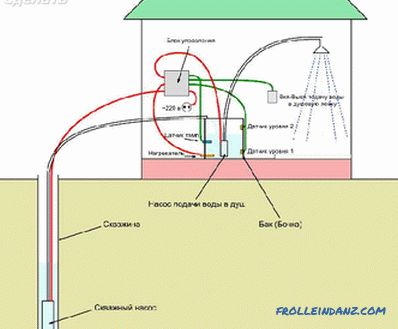

Circuit of a shower from a well

Circuit of a shower from a well

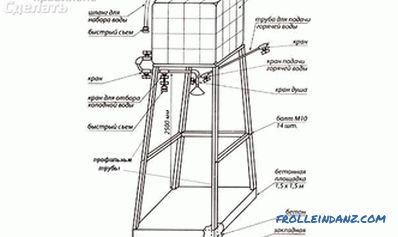

Scheme using a profile pipe

Scheme using a profile pipe

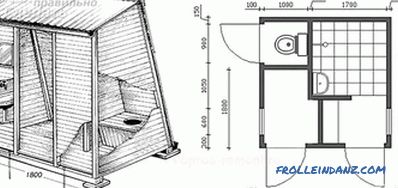

Construction of the dacha shower

Construction of the dacha shower

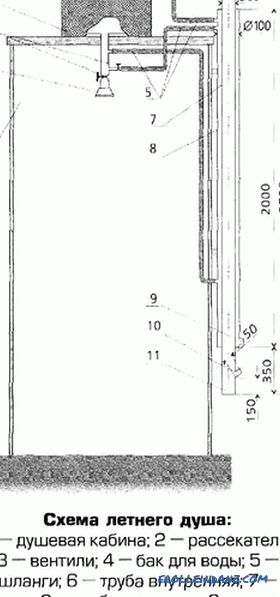

Scheme of the summer construction

Scheme of the summer construction

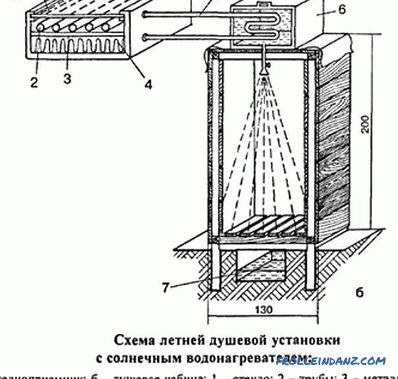

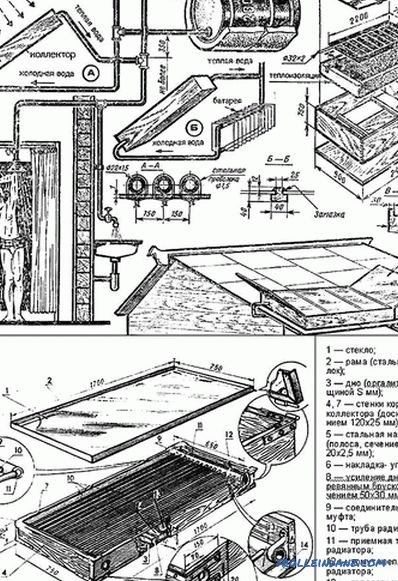

How to arrange water heating with solar batteries

How to arrange water heating with solar batteries

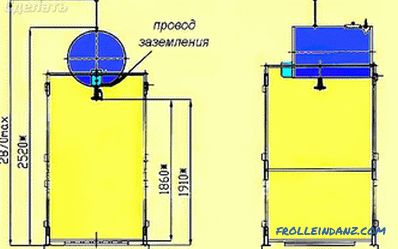

Connection of a plastic barrel in the

Connection of a plastic barrel in the

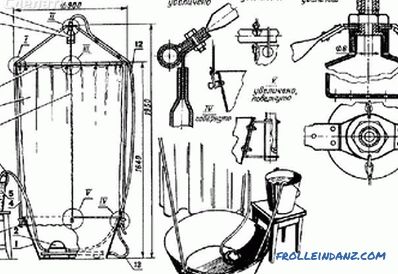

diagram. Manufacturing option for a portable summer shower

diagram. Manufacturing option for a portable summer shower