When building a country house, it is often necessary to do without the construction of a concrete staircase. No matter where it will be: in the house, in the basement or at the entrance to the house, you will need some knowledge - how to make a formwork for the stairs.

Staircase and formwork type

The ladder is a very complex building that must be comfortable, beautifully finished, durable and reliable, and most importantly - absolutely safe. For all these parameters, preference is given to the concrete stairs. She has excellent performance, aesthetic appearance. Concrete stairs are easily decorated with various facing materials.

Despite all this, it can be done by any home craftsman. The main thing is to make all the calculations correctly and know how to make formwork for the stairs.

The complexity and complexity of the construction of stair formwork directly depends on the form and its type.

A ladder located between two walls has the lightest construction - no side formwork should be made. The walls themselves perform the carrier function. They are attached to the frame elements.

Formwork for a one-way stair is easy and simple to assemble. It is necessary to mount only one end formwork, as well as stair supports.

Production of stair formwork

Production of stair formwork

More complex formwork will require the construction of a staircase with several marches and platforms between them. For additional details, various formwork elements, columns and supports will be needed.

The spiral concrete staircase has the most complex formwork. It is very difficult to manufacture, time consuming and requires serious financial investments. The formwork consists of numerous details of a curvilinear form, a set of support.

Calculation of the staircase

Calculation of the concrete staircase

Calculation of the concrete staircase

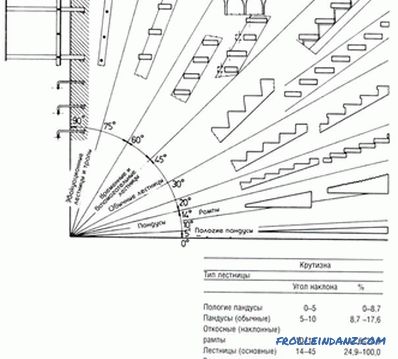

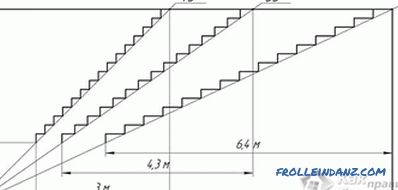

The main thing in the calculation stairs is the angle of its rise. The most common is the limit of 25 to 45 degrees. Stairs with a sharp lift angle require less concrete, but are difficult for older people to use.

Main slopes of the stairs

Main slopes of the stairs

The second step is to calculate the width and height of the steps.

We should not forget about all construction standards that must be strictly followed when calculating the staircase.

Assembling the formwork

Reliability and longevity, the beauty of the future concrete staircase depend on the correct assembly and strength of the formwork.

Edged board and waterproof plywood are the main elements of the formwork.

The lower part of the formwork

The lower part of the formwork

It is made for the whole staircase or separately for each step. It depends on where the future ladder will be located and what form it has.

For mounting the formwork you need:

- edged board (30 mm), waterproof plywood (20 mm);

- construction bar (100x100).

Side elements

Side elements

Main formwork details:

- Sections of timber, which connect the details of the formwork with each other.

- Bar for connecting elements of forming steps, which serves as an obstacle to the stretching of sheets during concreting

- End formwork. It is made of plywood on a pre-made pattern.

All formwork details should fit snugly together. Slots and grooves are not allowed.

The formwork is assembled with self-tapping screws. Typically, professional craftsmen use phosphated screws. They are black with incomplete thread. The use of nails is not recommended, they are then hard to pull out when dismantling the formwork. To facilitate the connection of parts among themselves use metal corners and short bars.

Manufacturing formwork

Manufacturing formwork

For the work on assembling formwork you will need the following tools:

- Plummet and level.

- Hacksaw or jigsaw.

- Screwdrivers or screwdriver.

- Hammer.

Tools must be in excellent condition - this will protect against injury.

When fixing the supports, the heavy weight of the concrete must be taken into account. The stands of the assembled formwork, before pouring concrete, should stand on the ground or the floor, and not hang in the air. To avoid this under them, you can put lining or drive wedges. The whole structure is connected to each other with planks - this increases its rigidity.

The last stage of formwork assembly is reinforcement. This will give strength and rigidity to the whole structure. Usually use ribbed reinforcement with a wire diameter of 10 to 12 mm. Elements of reinforcement are interconnected soft wire.

Concreting

Filling with concrete

Filling with concrete

Concreting the stairs produced at one time. Starts pouring from the lower steps. Rubble is added to the concrete so that it does not flow out of the formwork.Be sure to use an electric vibrator. This will allow to compact the concrete and prevent the formation of air cavities. After drying, the formwork is dismantled, and the stairs are decorated with railings and various decorative materials.

Good knowledge of the question - how to make a formwork for a ladder, will allow you to quickly and efficiently do this work.

We recommend you read:

- how to make a spiral staircase with your own hands;

- how to make a wooden staircase to the second floor;

- how to choose punch for home.

Video