In any home there is always some kind of furniture. In the kitchen, most often used table, all sorts of wall and floor cabinets, simple stools. These seats have a fairly simple design, they are not very beautiful and expensive materials, but their cost is quite considerable. But you can make a decent stool with your own hands from the simplest materials. The product will be very cheap, but it will look no worse than from a furniture store. How to make a stool with your own hands?

Picture 1. For the manufacture of a stool, you can use new sheets of chipboard, and you can use the remnants of old furniture.

Preparation for work

To manufacture a stool (image No. 1), you need to find a couple of pieces of chipboard. It may be new sheets, you can use separate parts of the old furniture disassembled. For a test sample, it is enough to prepare:

- DSP 40x30 cm - 2 pieces;

- DSP 30x30 cm - 1 piece;

- Chipboard 20x12 cm - 1 piece;

- pencil;

- ruler;

- drill;

- drill with a diameter of 5 mm;

- ; electric jigsaw;

- a screwdriver;

- Confirmats 6.4x50 mm - 4 pieces;

- furniture heel of any shape;

- furniture corners - 4 pieces;

- several small screws;

- sanding pelt;

- tape for processing edges;

- electric iron;

- sharp knife;

- foam rubber and a piece of cloth or leatherette 41x41 cm ;

- stapler furniture.

Manufacturing stools

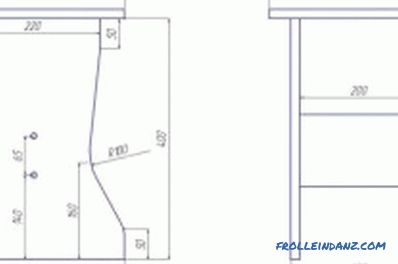

Figure 2. Drawing of a stool with dimensions.

To make a stool, you need to complete several stages of work:

- On the chipboard blanks, you must draw a full-size side racks, lintel and stool seat (image No. 2).

- Cut out the parts and round the corners.

- Drill the necessary holes in the details.

- Handle part edges.

- Assemble the stool.

- Mount upholstery (optional).

If you plan to make several pieces of stools, it is better to make templates for each part out of cardboard. Ready template to put on chipboard and circle with a pencil. This will speed up the process of work, and all the details will be performed qualitatively. Curved lines on parts or on a template can be applied by hand, but it is better to use a compass or a round object of suitable diameter.

Cut out the marked parts with an electric jigsaw (image No. 3). A file should have small teeth. The speed you need to choose the maximum. The edges in this case are smooth and clean. Small irregularities are processed sandpaper.

A special finishing tape is stuck on the edges of the parts. It must be chosen in color and width. The tape is coated with a layer of special glue.

Picture 3. The marked parts of the stool should be cut with an electric jigsaw.

With this layer, the tape is applied to the hem and smoothed with a hot iron, then a soft, clean cloth. This should be done pretty quickly. The heated adhesive mass cools down and firmly connects the tape with wood in literally several tens of seconds. Surplus cut with a knife.

A seat is screwed to the structure consisting of side struts and a jumper between them. This is done with the help of corners and screws. Stool do it yourself.

The seat can be made soft if desired. For this purpose, foam rubber is glued to its workpiece with the help of “Moment” glue, the surplus of which is carefully cut with a sharp knife. All this construction is covered with leatherette or fabric. It is better to fix the fabric with a construction stapler.

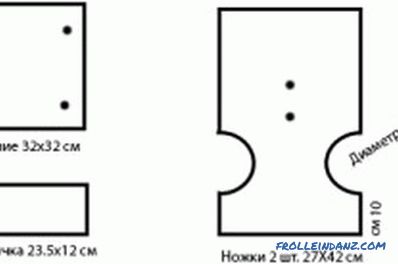

The assembly is completed by installing any type of thrust bearings in order not to scratch the floor covering with a stool. If you wish, you can use several other sizes of stools (image number 4). Only it is necessary to remember that its lower part should not be already a seat. Otherwise, the product will be very unstable.

In the same way, you can make a stool out of multilayer plywood with a thickness of 18-20 mm. Only the finished product will have to be further polished, primed and painted, covered with varnish. In all other respects, the manufacturing technology is no different from working with chipboard. If you wish, you can come up with your own models. Do it yourself with chipboard and plywood can not only stool. If you add a back to it, you get a chair.

Notes of experienced craftsmen

Picture 4. Schemes of various sizes of stools.

- When upholstering a seat, remember that leatherette is a fairly dense material. If you stand up from a stool, it will take a long time to its original shape. To avoid this, you need to drill 4-5 through holes at the base of the seat for free air flow. You can drill them both before assembly and after assembly of the product.

- In order for the dermatin to look more aesthetically pleasing at the corners of the seat, the material folded in the folds needs to be heated with a hot iron through a damp cloth. In this state, it fits much better and after cooling, retains its shape.

- Furniture of this kind is characterized by great practicality and durability. It can serve not only for its intended purpose, but also as a stand for various objects, as a replacement for a stepladder.

It is possible to make a kitchen stool from a chipboard at home from ordinary scraps.

This material can be found in many garages and sheds after dismantling old home furniture. You can purchase substandard material in stores at woodworking enterprises. It will make excellent furniture that meets your needs. Very often, after making the simplest stool, there is a desire to make a chair, a wardrobe and more complicated things.

Didn't find the answer in the article? More information on the topic:

-

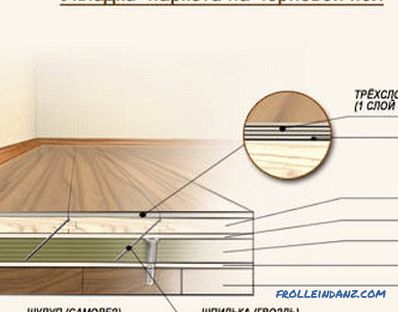

How to lay a wooden floor in a private house

In order for the wooden floor in a private house to serve for many years, certain laying rules must be followed. Better yet, make it multi-layered. This will improve the heat and sound insulation.