It is well known that in a modern garage building, besides the car itself, it is customary to store a large amount of special tools, auxiliary equipment and other materials.

To place all of these items necessary for servicing a car, special racks or shelves should be provided, the manufacture of which should be worried in advance. In our review we will try to talk about how to make racks in the garage of various materials, as well as consider some of the nuances of the organization of work on the manufacture and collection of shelves.

Types of structures

Types of racks

Types of racks

Different options for making racks for the garage suggest use for their arrangement of structures of the following type;

- metal;

- designs made of wood materials;

- combined (metal frame plus wooden shelves).

In addition, there is a difference in the way they are installed and there are, in accordance with this, the following versions:

- Prefabricated metal structures that are mounted on any, convenient for you height and fixed on the walls with special mounting angles (using bolts and nuts). Caracas for shelves of this type can be racks of perforated metal profile.

- Stationary structures, the frame of which is mounted from solid horizontal racks, fastened to four vertical racks. Structures of this type are able to withstand a large load, which in this embodiment is completely transferred to the floor. As a rule, metal blanks serve as the starting material for such racks, but if the load on the shelves is small, you can use wooden materials for their arrangement.

- It is possible to use movable structures equipped with special rollers, thanks to which they can be moved to any place convenient for you. Unfortunately, structures of this type have certain restrictions on the load.

- And finally, you can equip hinged shelves, suspended directly under the ceiling, at a height convenient for the owner of the garage. To arrange such a construction, it will be necessary to prepare special fasteners that are freely sold in any building materials store.

Making the shelves yourself

Assembling the shelves

Assembling the shelves

Similar to working with constructions of any other type of independent production of shelves in the garage should begin with drawing up a sketch in which their location should be noted and all characteristic dimensions indicated. Optimal is the option of placing shelves along one of the walls, freed from all unnecessary items and things.

The depth of the racks and the distance between the contours is chosen based on the maximum size of the items to be stored on them. The distance between the two lower shelves should be chosen to calculate the possibility of storing them on automobile tires and jerrycans.

Metal shelves

Before arranging the metal shelves in the garage, you will have to prepare for them a robust frame made of standard corner pieces. Fastening it to the racks is made by welding or by conventional bolting.

In the second case, you will have to prepare a whole system of holes, designed so that in the future you can adjust the shelves in height. All metal components of the structure (rack and frame) will need to be primed, which will provide them with reliable corrosion protection. As a material laid in a frame structure, it can be used as a regular board, as a chipboard or multilayered plywood. To fix them on the metal frame is best to use conventional screws.

To increase the structural strength of the structure, it can be additionally fixed to the wall (or ceiling) of the garage with the help of special brackets.

Shelves made of wood materials

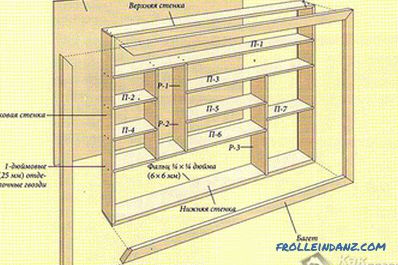

Scheme of manufacturing a rack of wood

Scheme of manufacturing a rack of wood

If you want to save on material, you can make a racking design completely from wooden blanks. As racks, you can choose a standard bar with a cross section of at least 10 * 10 cm, and for shelves you can use a board or sheets of plywood 1.5-2.5 cm thick.

It must always be remembered that the carrying capacity of the timber structure is noticeably lower than that of its metal counterpart. In addition, such racks are much more dangerous to use because they are made of flammable materials.

Video

This video shows the production of wooden shelves at an accelerated pace.