A variety of ways to use wood for interior and exterior decoration determines the presence on the market of a large number of materials necessary for this, each of which in turn is divided into varieties, varieties and classes. Types of lining, thin planed board for surface cladding, for the domestic buyer are primarily divided into ordinary and euro. Further selection depends on the need to use softwood or hardwood boards, which profile will be better, as well as the price / quality ratio, which is determined by the type of wood.

Plain and lining

With its name, lining is required to preserve loads from the sun and rain that were transported by rail before the introduction of modern materials. The use of wood for covering cars was most appropriate, since it is not only cheaper than iron, but also better prevents the greenhouse effect. Initially, the boards were fastened in the usual way, but over time, to simplify installation and prevent cracks, in case of any deformation, they began to be made tongue-and-groove locks. The idea was appreciated and such boards began to be widely used in facing works.

In other languages, there is no such binding to the origin, therefore, when visiting overseas construction stores, you just have to look for profiled boards. For their manufacture, the standard DIN 68126/86, developed in Europe and, according to a number of requirements, being more stringent of local GOST, is applied. Accordingly, the exported products, or simply manufactured according to DIN standards, are familiar to the domestic buyer as eurolining.

The usual lining, made even by Soviet standards, the builders make a large number of claims - both in performance and ease of installation. Humidity in 20-25% is too high - with a board thickness of 20 mm during drying, deformation often occurs, with which small locks, trying to jump out of the groove, cannot cope. The fleecy surface and the number of knots, which are not particularly controlled, make not only the shape, but also the quality of such products unimportant.

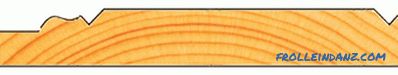

Profile of standard lining manufactured according to GOST.

As a result, Lining, despite the price, is much more readily used by builders due to its advantages:

- A more thoughtful form: a large spike is not afraid of deformations, the optimum thickness and the width of the lamellae (12.5 and 88 (excluding the spike, with it - 96) mm, respectively), the presence of ventilation grooves, the ability to select a profile pattern.

- Pile on the front side is not allowed, careful processing of the thorn-groove lock for ease of installation.

- The entire eurolining is dried to a moisture content of 10-15%, which negates the possibility of its deformation and the likelihood of the appearance of bugs or rot. Dry boards are easier to store, process and care for them during operation.

- After cutting wood, boards, depending on quality, are divided into at least four grades, taking into account manufacturing defects and the state of the wood itself.

Types of lining profiles

As the lining is used for cladding many surfaces, manufacturers take into account the desires of customers to give their premises a certain personality and make several types of profiles that can be selected not only in appearance , but also for certain types of work. Profiles differ from one another by the presence or absence of chamfers, the types of locks, the shape and size of the front and back sides.

Traditional eurolining

An additional chamfer was chosen on the front side of such a profile near the tenon, as a result of which, after mounting, pronounced seams are visible on the wall. Chamfer can be angular or rounded. Rounded received name Softline.

Lining "Softline"

Since this shape of the surface has no corners, the probability of chipping and burrs is less during operation, so Softline is considered more suitable for such rooms as a sauna.

Lining "Calm"

The difference of this profile is the lack of chamfer near the spike, so the joints are not so bright after installation expressed as when using traditional lining. This is used if necessary to create an imitation of a wall assembled from a bar, so most of the “Calm” lining is produced thickened up to 25 mm and can be freely used for cladding facades of buildings.

Lining "Landhaus"

Lamels, which include such types of wooden lining, one of the most expensive, so As with their production, the front side is subjected to milling or other processing methods that form complex patterns on the surface of a tree. There are even profiles with the effect of woodcarving, which is obtained using hot stamping under pressure.

Blockhouse lining

If the Calm lining imitates walls made of bar, the Blockhouse profile has a completely rounded front. Thanks to this solution, after assembly, the wall looks as if the house is assembled from rounded logs. Mainly used in cladding facades of buildings.

American-style lining

In this profile, the chamfer is not just removed from the spike, but a smooth transition is made from it and to the middle of the front. With this solution, an imitation of the siding panels is achieved exactly, but the house is lined with natural wood.

Double-sided lining

Such a profile does not have a back side - both its parts are made from the front. Such lining is useful in case of need to make a thin wooden partition. Also, when facing a wall, it is possible to choose a better pattern or place small defects on the back side.

This paneling is not strongly recommended to be used in rooms with high and variable humidity, as it is the only one of all types of Euromask that has no compensation (ventilation) channels.

Grades of lining

Unlike other materials, which, depending on their value, are treated differently, all of the lining is made using the same methods, one lot and goes through the same machines. Fully finished boards are sorted depending on the presence of cracks, knots, resin pockets, poorly treated areas (unevenness) and pronounced blue color on them, which is a result of improperly drying wood.

Also, when buying a wall panel, it is necessary to take into account such an unpleasant moment that each manufacturer can sort products based on different guests, or develop their own technical conditions. As a result, if there is no confidence in the products of a particular manufacturer, then it makes sense to double-check at least some of the boards before purchasing them.

Extras

Additional names - "without a bit" or "premium." Even minor imperfections and cracks on the front side are unacceptable, so this profile does not need additional processing. On the running meter, the presence of one healthy light knot, but without cracks and other defects near it. In the presence of opened resin pockets, the resin is removed, and the area is puttied and cleaned with fine sandpaper.

Class A

In such profiles, 2-3 knots per running meter of the product and small chips near them are allowed. On the front side there may be minor imperfections and microcracks (depending on the manufacturer - puttied). Also allowed the presence of end cracks, but no larger than the width of the board. Core-made profiles should not exceed 20% of all boards in a package. If boards from coniferous breeds of a tree, then the insignificant salting is allowed - no more than 10% of the total. The total color can vary on small areas of the boards (up to 10%) for every tenth of them in the package.

Class B

On one board the presence of two drop-down knots is allowed, as well as cracks - on the front surface up to 300 mm long and end faces. Fallen knots with a diameter of not more than 20 mm are allowed on the edges of the board. Boards can be from the core part and with resin pockets. If they are made of coniferous species, then the surface salinity is permitted. In three places on one board, places affected by insects are allowed, but not more than 5% of the total number of boards. Improper coloring is allowed except for blue and uneasy if they do not affect the build quality.

Class C

This class includes all boards that did not fall into higher categories and which can be used for its intended purpose. The use of rotten boards is clearly forbidden, but there are no restrictions on all other parameters. In such profiles there can be holes from knots with a diameter of more than two centimeters, through cracks and pitch pockets, tarring and sprouting, insect-affected areas, discrepancy of color. Neprostrogi and other defects are also not limited, unless they affect the stability of the surface. By size, boards of any grade are manufactured according to the following tolerances: length ± 50 mm, width ± 1 mm and thickness ± 0.5 mm.

|

|

| |

|---|---|---|---|

| Class A | Class B | Class C | |

| Knots | The following are allowed: knots without cracks, no more than 2-3 pieces per 1 meter of board; cracks and chips on knots from the side of the ridge and from the side of the groove on the lower edge, which are imperceptible when assembled. | Drop-downs with a diameter of up to 20 mm and dropped out with a diameter of 20 mm are allowed - no more than 2 pieces per meter of board. | Fallen knots with a diameter greater than 20 mm are permissible. |

| Cracks | The following are admissible: butt-sized and with microcracks. | End face dimensions of 300 mm are permissible. in the direction of the fibers. | Valid. |

| Core | It is allowed to be no more than half the size of a board in 20% of the boards from a package. | Valid. | Valid. |

| Redwood | Allowed in small quantities. | Valid if will not affect the assembly. | Valid. |

| Resin pockets | Allowed with a diameter of not more than 6 mm, 2 pcs. the length of the board. | Valid. | Valid. |

| Pitted areas | Not heavily salted areas are allowed in 10% of the boards from the package. | Valid. | Valid. |

| Strength | No more than half the width of the boards is allowed. | Valid. | Valid. |

| Insect damage | Not allowed. | No more than 3 pieces are allowed. the length of the board in 5% of the boards from the package. | Valid. |

| Rot areas | Not allowed. | Not allowed. | Not allowed. |

| Difference of color | Acceptable in 10% of boards per 10% of the board area. Blue is not allowed. | Bands allowed. Blue is not allowed. | Valid. |

| Processing quality | Fine roughness and indentations on the edge in the knot area are permissible. | Gouging defects are allowed that do not affect the assembly. | Gouging defects are acceptable without impairing the quality of the finish. |

Types of lining depending on wood species

Any kind of wood is used for the production of lining. The choice between them depends on the required characteristics that I would like to see on the treated surface, the types of lining for interior decoration or exterior works are selected, as well as the budget that can be allocated for its purchase. The main division goes on the boards received from coniferous and deciduous breeds of wood.

Coniferous breeds

It is characterized by the presence of essential oils and resins that put a natural barrier to moisture and various fungi, therefore such a wall paneling is most often chosen for use in outdoor decoration. They are also veneered with walls in baths and steam rooms, but for this board are carefully selected and the process of removal of tar. Lining of the needles favorably has a long service life, which can be several decades.

Spruce . Due to the natural softness of this tree, it is more often used to produce lining with rounded shapes. Designers often recommend this material for interior decoration, the design of which is made in any of the modern styles.

Of the physical characteristics, a low roughness index and a beautiful surface texture without pronounced patterns stand out.

Due to its relatively low cost and strength properties, such wood is widely used in exterior and interior decoration. However, one should take into account the high level of hygroscopicity of spruce boards - in order to increase their service life, they should definitely be treated with appropriate chemicals.

Pine . Such a wallboard can be considered the most budgetary solution among all the conifers, which, however, does not detract from its characteristics regarding the appearance of boards and their durability.

Pine clapboard has only two significant drawbacks that you should pay attention to before buying:

- Low density of wood, which, although it reduces the overall weight of the coating, makes it vulnerable to scratches and similar damage.

- Pine boards, even when properly treated, emit resin drops for a long time, which is especially unpleasant when used in the finishing of a bath. If in the steam room to lean against tarred wood, it is almost a guaranteed burn.

Larch . The only drawback that can be found in such coverage is the high cost, which is completely determined by its quality.

Among the advantages, first of all, the strength of this wood stands out, which is not only high by itself, but also increases with time, exceeding by about a third the performance of boards made from the rest of softwood.

The characteristic structure of larch not only determines the beauty of the boards, but also gives them exceptional thermal insulation properties. Resin contained in wood fibers is a natural barrier that protects it from moisture and insect pests, as well as retains a natural reddish tint throughout its life, which looks great on any surface.

Cedar .Natural impregnation of cedar planks with resins gives them a strong characteristic coniferous smell, which has a beneficial effect on the human body, and in particular on the nervous system.

Cedar lining is an excellent heat insulator, and also due to its high density it has high resistance to mechanical damage. With proper processing, cedar planks retain all their properties for several decades, which allows them to be used both in the interior and exterior.

An additional "bonus" that is received by the owners of rooms decorated with cedar clapboard is the absence of mosquitoes who do not like the smell of this tree.

Lining from pine.

Hardwood

Since there are no resins and other volatile substances in the composition, these types of lining are mainly used for interior decoration, including rooms in saunas and baths. The general lack of such materials is lower durability, but often this is compensated by low thermal conductivity, which allows them to be used in rooms heated to high temperatures.

Lipa . It has a relatively low cost, exceptional resistance to mechanical damage, deformation and moisture, which makes products made from such wood an ideal solution for use in baths or for finishing balconies.

A significant disadvantage of such a wall panel is that it darkens noticeably with time, so the linden boards necessarily need additional treatment with impregnations to prevent rotting of the wood.

Alder . When heated alder boards, they release volatile compounds from the tannins contained in the wood into the air. In addition to the fact that the nature of these compounds has a beneficial effect on the human body, the tree itself does not absorb moisture, so it is successfully used in the decoration of rooms where high air humidity is assumed.

Other advantages of the material include low thermal conductivity, high sound insulation properties and characteristic colors, due to which the alder is easily recognizable when used as a finishing material.

The disadvantage that will have to be avoided is a relatively low service life, which is corrected by the use of protective compounds.

Oak . Products from this tree were and remain the elite "classics of the genre", differing in unsurpassed quality and corresponding cost.

High strength characteristics affect not only the further operation of products, but also the cost of processing of which also adds up their price for the final buyer. Also, the prices for oak lining strongly depend on its length, and for facing rooms in the bath, designers just recommend choosing long and narrow boards that will create a more holistic design.

Lime liner.

Valuable, exotic breeds

Most often exotic means products made of mahogany. Since the habitat for it is exclusively tropical forests, in the domestic market, such products are infrequent and the cost is quite high. Despite the good physical characteristics, such wood is suitable for all types of processing, and the sizes of tree trunks make it possible to produce lining of almost any size. Mostly it is used for interior decoration.

Dimensions of wooden lining

For various purposes, lining may be needed with a certain length, thickness and width, but this is not any noticeable problem, as it is made in many sizes, and in length It is generally sold with boards from 0.3 to 6 meters in 10 cm steps.

Be sure to take into account that the wider the wall paneling, the greater the likelihood of its deformation with changes in temperature or humidity. Accordingly, narrower boards maintain geometry better, and also have greater resistance to shock loads and other mechanical stresses. A certain decorative effect can be achieved if boards of different widths are randomly installed. This method of installation has virtually no effect on the strength of the resulting surface.

In terms of thickness, the best option for interior work is lining with a size of 12.5 mm - this is the calculated optimum ratio of weight and strength. If you use lining for exterior work, it is better to select the thickness within 15-20 mm, although it will be more expensive - such lamellas are capable of holding not only their weight, but also a sufficiently thick layer of insulation materials.

Long wall paneling is not necessarily made from a single piece of wood - the method of splicing boards along the length is often used, when pieces of 150-750 mm are joined into one lamella.Docking is done on the micro-bearing, and the junction itself is additionally glued and is kept under pressure until the glue dries.

The disadvantages of spliced lamellas are more related to their use in interior decoration:

- The splicing technology does not allow getting a board thinner than 15 mm, which affects its weight and cost .

- There is no way to find out what kind of glue was used in production, and whether it will not release harmful substances when heated - this factor often keeps consumers from buying who are going to build a bath.

The advantage of lining produced by this method is the absence of internal mechanical stresses of the material. The total length of these slats is up to 6 meters, and by grade they can even be of the Extra class.

As a result, it is clear from the listed varieties and characteristics of the wall paneling that the range of this material offered on the market can fully satisfy the needs of any customer: in terms of quality, quantity and cost.