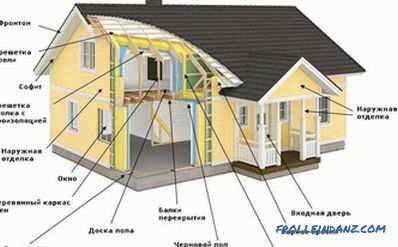

Rafters are a constructive special element that is being built during the construction of pitched roofs. It consists of several basic elements, to which can be attributed vertical pillars, rafter legs and inclined struts. In some cases, they are connected to the bottom with beams. Usually rafters are made of timber. For fastening using special hardware. About what are mounting for rafters, and it is worth to talk in more detail.

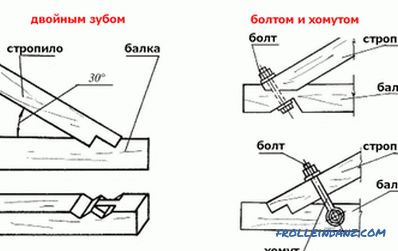

Truss connection options.

Rafters and plates for fastening them

These elements can be different. The systems themselves are most often made in the form of a triangle, but sometimes alternative options are also used to save space. An example is the attic location. In this case, the location of the rafters is such that it allows you to free up additional space where people can live. Very convenient method of arrangement of the system.

Fasteners for rafters can be varied. Fasteners are used to connect the elements of the roof together. Here we can distinguish the following types of it: plates, sliding supports, angles, supports, truss-beams, and so on.

Knots of fastening of rafter system.

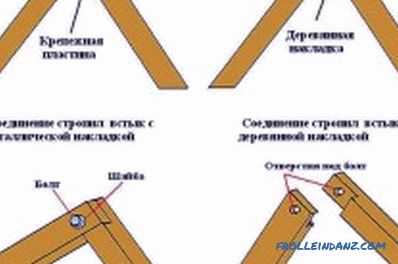

Plates in this row occupy a special place, since they are almost universal elements. They contain special holes through which screws are screwed, which serve to connect two or more structural elements together. In this case, the plates are superimposed on the parts to be joined on both sides. They can be easily cut with metal scissors to the desired size. After all, it is not always about universal installation.

There are also nail plates with a row of nails on one side. They are used only in industrial environments. Nails can not be hammered. Here fastening is carried out by squeezing the elements together. Mounts for rafters of this kind are very widespread among both professional builders and amateurs.

Reliable fasteners for rafters

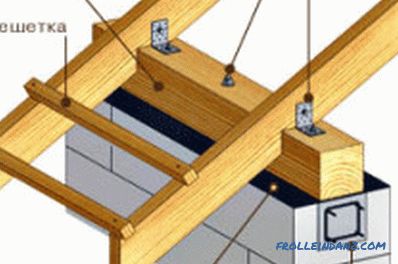

For connecting perpendicular structural elements, truss-beam fasteners are used. These structural elements rest on each other in the perpendicular direction. In order to make the fastening more reliable, a pair of connecting elements are installed in opposite directions. One of them unfolds in the opposite direction.

Sometimes a situation arises when it is necessary to position the structure at a certain angle. This placement is used in buildings of timber. Sliding rafters are used in this particular situation. Parts may not always be fixed. Sliding systems provide an offset for structural elements in the event of shrinkage of the roof. A very important element of the entire roofing system, which allows in the installation process not to make allowances for wood shrinkage.

The scheme of fastening rafters to the power plate.

Beam supports will help to fix horizontal structural elements at right angles to all other parts of the roof. Of course, if necessary. Here fastening to the main support can be done with nails or screws. There is no fundamental difference. The most important thing is that the mountings for the rafters should be well kept in their rightful places. Support beams can have a variety of structural dimensions. It all depends on what specific elements with their help will be connected.

The hidden bracket of beams is used in cases when the installation must be hidden from prying eyes. After its installation, such an element hides entirely in the body of the beam.

Other attachments for rafters

Above we have listed only the structural main elements that are used to connect certain parts of the rafters. However, in this series there are other equally important fixtures for rafters, which are also used quite often.

One of those is the profile corner. This means that you can buy a corner in any specialty store that distributes metallic building materials.

The corners can have a wide variety of geometrical dimensions.

With their help, structural elements of rafters are connected to each other at right angles. If corners specially designed for work with the roof are used, then they have special holes through which the fastening is carried out. In this case, you need to use screws, as the nails are not able to provide sufficient rigidity of the structural elements.

Schematic of fastenings of flat rafters.

If we are talking about homemade corners, then you need to cut them to a certain size specified in the documentation on the roof. Next in the elements are drilled holes for connecting the rafters. Everything is quite simple.At the same time, you can save a lot of money, since ready-made corners are quite expensive. These elements are most often used to connect vertical beams with horizontal ones. Fastenings for rafters of this kind are widely distributed.

Some manufacturers offer to buy angles with oblong holes. They are specially designed for bolting. This is quite an interesting method of connecting parts. When shrinking, it will be possible to adjust the position of the constructs relative to each other. Are issued corners and at an angle of 135 degrees. They are used to connect elements at an angle to each other. The structure of the roof is quite complex, so they find their application here.

The T-shaped mount for rafters is also used very often. It provides a reliable connection of all perpendicular elements to each other.

Some features

In modern life, there are fasteners for rafters, which have very original names. An example is a crutch. This name he received for a reason. Such a device is used to connect the rotten elements of the truss structure. First you need to hammer it into the masonry, and then connect it with the beam.

Ridge connection scheme of the truss system.

If you use not perforated fasteners, but not perforated fasteners, during the construction of the roof, you can significantly speed up the process of connecting parts together. This results in a more rigid construction, which will not be scared of any external aggressive factors.

Thus, it can be considered that today numerous fasteners for rafters have been applied. All of them are used for certain purposes. Today, you can easily build a roof of the highest quality thanks to the development of fastening materials. Now you can purchase almost any element that connects the parts of the truss system to each other.

Moreover, this connection is not necessary to be located at a right angle or lie in the same plane with the beam. Here you can safely talk about mounting at an angle. This allows you to build competent facilities, in which there are no unnecessary details. At arrangement of a mansard roof not to do without special fixture. Save space is possible only if some elements will connect at a certain inclined angle.

Having considered the main features and nuances of such products and methods of working with them, you will be as informed as possible about the upcoming process and will be able to correctly make the right choice when buying. Good luck!

Didn't find the answer in the article? More information on the topic:

-

How to properly level the wooden floor

How to level a wooden floor with your own hands without using complex technologies? For wood flooring, fiberglass leveling compounds are the best and practical option.