The construction of a frame house is considered simple and can be built in a short time. Therefore, the question of how to build a frame house with your own hands, is becoming increasingly popular. Such a house can be built on a plot not only for temporary, but also for permanent residence, and during construction it is necessary to take this into account.

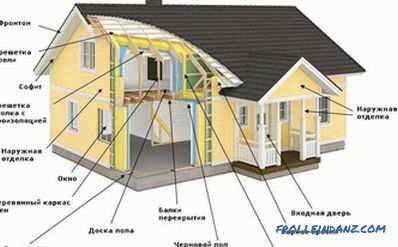

The layout of the frame house.

The cost of building such a dwelling will in any case be lower than a stone house. Simplicity allows you to engage in frame construction individually, possessing only basic construction skills.

Frame house construction - materials and tools

The list is quite impressive, but all these materials are affordable and popular, you can find them in almost any building shop. To build a frame house yourself, you will need:

Tools for building a frame house.

- concrete;

- reinforcement;

- waterproofing materials;

- boards (pine);

- insulation;

- polyethylene;

- plasterboard;

- lining or siding;

- metal tile;

- pipes, wires, etc. for various utilities;

- hammer;

- planer;

- chisel;

- nail-catcher;

- jigsaw;

- saw;

- construction level and plummet;

- drill;

- screwdrivers and screws;

- marker, pencil, construction chalk;

- step ladders, stairs, construction forests;

- brushes;

- antiseptics on wood.

Frame house with your own hands: foundation

Frame houses do not require a strong foundation, since they are light enough, shrinkage of the soil after construction is complete. They are made on screw piles, a strip of shallow foundation or columns. The choice and laying of the foundation depends largely on the type of soil and the number of floors of the planned building. If a simple one-story house is supposed, then even on capricious soil you can get by with just a columnar foundation.

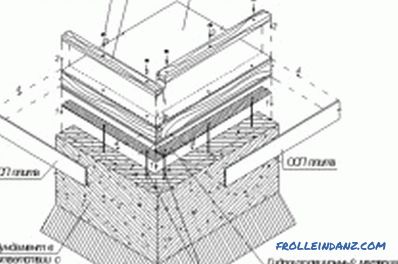

Scheme of the foundation of a frame house.

Building a small one-family summer house with a columnar foundation will require acquiring 120-150 columns for the foundation. Recesses are made in the ground with a diameter of 20 cm and a meter depth; an ordinary drill will be needed for this work. The distance between the holes is made about 80 cm, asbestos-cement columns or pipes are inserted inside. The free space left on the sides is tamped down, filling it with sand and rubble. Cement mortar is poured inside the posts; The advantages of such a foundation are that in order to continue the work, it is not necessary to wait for the concrete to solidify.

For the construction of a frame house with your own hands, a screw pile foundation is often used, which is currently very popular. It can also be made independently, without the involvement of workers and special equipment. On the contrary, for the foundation of piles, manual work is preferable, since they need to be screwed strictly in level. It is strictly forbidden to unscrew the piles after their installation. This breaks the tamped soil and may eventually lead to a skewed building, so it is preferable to leave the screwed up pile in place or turn it into the ground completely.

Technologies for the construction of a frame house

The technologies for the construction of a frame are conventionally divided into Finnish and Canadian. In fact, no matter what technique the master chooses to build, the steps and basic principles remain the same.

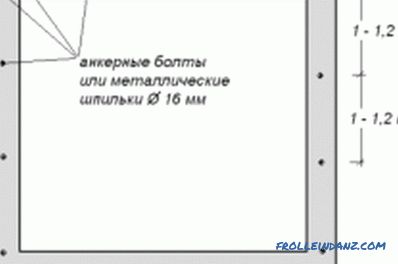

The layout of the studs for fastening the strapping bar.

Frameworks for the house, depending on the desires of the owner, can be steel or wooden. The most common are steel frames, hammered together from a bar, as they are easy to install, eco-friendly and inexpensive, are easy to install. Steel frames are priced at a third, on average, but since they are lighter, their use will save on the foundation. Steel fasteners can be safely used in metal frames, whereas for wooden structures it is preferable to use wooden pins.

By erecting a frame house, first of all, the floor is made, for which ruberoid is laid on its basis, it will prevent moisture from entering the foundation. Then, along the perimeter of the box of the house, a bar is installed for the foundation of the subfloor to outline the contours of the future premises and interior walls. Rough floor is made using one of the most costly materials - unedged boards. But before laying the boards of the subfloor, lags are laid out, and between them there is a heater that protects from moisture and cold. Boards and logs before the final layout must be treated with antiseptic or paint, so their service life will increase. All the correctness of the geometry of the house under construction depends on the calculation of the subfloor, and their location should be checked with a level several times.In this case, the angles deviation from the horizontal should not exceed 10-12 mm, and the boards are fixed with anchor bolts. The distance between the fasteners should not exceed 2 m, brackets can also be used for strength and compaction.

Following the assembly of the floor of the frame house, install walls. First you need to fully assemble them on a flat surface, and then completely install vertically.

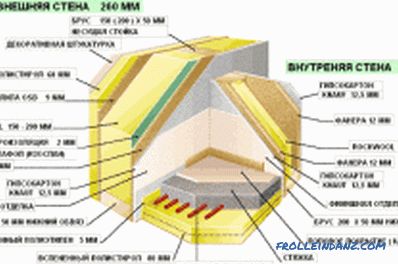

The layout of the walls of a frame house.

To knock down the walls of a frame house, you must choose a completely flat place, and collect all 4 walls there: otherwise, distortions are inevitable. First of all, it is constructed from a bar with grooves, the distance between which is no more than half a meter, the lower binding. The grooves are used both straight and with a bevel, they are also used to connect the edge of the bars.

When installing the walls, the ceiling height is determined, which is desirable to limit to 2.5 meters. This height is quite enough, and after a variety of decorative finishes, this ceiling will not fall below 2.3 meters.

Low ceilings in the room are not recommended, as this is depressing and a fire hazard, but a room with too high ceilings is more difficult to heat.

For this, vertical boards are measured and sawn of the required length. Then, in the locations of the racks, vertical pins are placed and the frame begins to be assembled from the corner bars, installed vertically. The bars, inserting them into the dowels, are fixed with temporary laths, other intermediate bars are installed in the same way.

When all intermediate bars are installed, the upper part of the strapping is constructed. The same bars with grooves and the same principle that was already involved in the assembly of the bottom are used. The location of the top and bottom should be identical, it is checked repeatedly in the process of working with a plumb and level, as otherwise the house can be very twisted.

Scheme of warming of walls of the frame house.

The upper strapping, unlike the lower one, is fixed with nails, and their length must be so great that they are not less than 10 cm into the ends of the vertical bar. Temporary jibs are dismantled, replacing them with permanent ones, they should not be completely removed. They give the frame additional strength and remove some of the loads from the upper and lower straps.

Then a bar is attached that serves as the ceiling beams. Each beam must be no more than half a meter from the other and must coincide with the vertical posts. At the same time, support bars are installed inside the house, they support the beams and are the basis for interior partitions.

After the walls of the frame house are installed, it can be sheathed with boards outside. The installation of windows for the house with their own hands should also be given close attention. It is believed that the size of the windows should not exceed 20% of the size of the entire wall, but otherwise any double-glazed windows can be chosen. Trim frame house also sandwich panels or siding, and when installing the roof you need to make sure that it does not flow.

Warming the house with your own hands

In order for the dwelling to become habitable, you will need to warm it up and then carry out communications and complete the final decoration. The choice of materials for warming a frame house takes a lot of time.

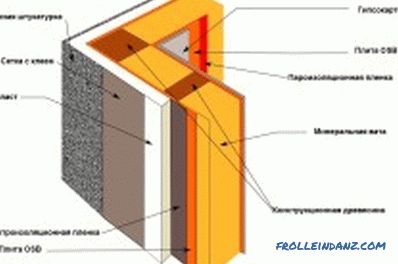

Steam insulation system for the walls of a frame house.

It is possible to make insulation both from the outside and from the inside, the preferred option for interior decoration of the house is drywall and mineral wool as insulation. An even better option in construction is vinyl drywall, with the same insulating properties having more pleasant aesthetic characteristics. With the use of this material the question of warming and interior decoration will be solved.

It is necessary to warm the house from the outside before it is upholstered with clapboard or siding, all works with thermal insulation should be carried out by this time. The first stage is the batten, between the cells of which and the walls are stacked layers of mineral wool. From above it can be covered with foam, and the gaps, if they are formed, fill with foam. The house outside can be warmed and in the absence of crates. The walls are treated in the same way from the inside. Insulation fits between the racks, additionally closed on top of the foam.

Vapor barrier of a frame house

A vapor barrier is necessary in a residential house, as it inevitably contains a bathroom and a kitchen, and these places are the sources of high humidity. The level of humidity in these rooms sometimes exceeds this figure outside. It is a vapor barrier that is often made with several common errors and does not work as a result. Often, instead of factory steam insulators, homemade materials and polyethylene are used.The film intended for vapor barrier is really very similar to polyethylene, but unlike it has a multi-layer structure on which condensate does not form.

Errors include a careless installation, during which the membrane breaks, or its seam diverges. Often the film is glued to the walls is not enough quality and quickly loses adhesion. Sometimes, as a result of confusion, a membrane is installed outside the box at home, whereas wind-proof films are more appropriate there. Vapor barrier should always be located indoors, even if the walls are thin and insulated from the outside. Mounting the membrane, you need to carefully ensure that it is turned the right side.

The membrane must be mounted on a thermal insulation layer in order to protect it from moisture and condensate, since these factors severely damage its properties. Already after a couple of seasons, the insulant constantly exposed to moisture ceases to function. Since the boards in the process of building a frame house are used thin or medium thickness, its walls consist of insulation by about 70%. With the destruction of insulation layers, the house will have to be re-insulated, and this is almost equal in time and cost to building a new one. Therefore, vapor barrier should not be neglected.

The use of polyethylene instead of membranes leads to the fact that the air circulation in the house is disturbed, which polyethylene does not let in at all. This will lead to the appearance on the inner surface of the walls of molds, which poison the air and quickly destroy the plasterboard coating. Polyethylene seals the room and even forced ventilation does not save it.