Every person wants his home to have unique furniture made by himself. Making a table with your own hands is a fairly quick and uncomplicated process that can be realized even for a person who has not been involved in such things in life. The only important condition is to be able to handle the tool at least at the level of a confident beginner, so that there is no waste of materials.

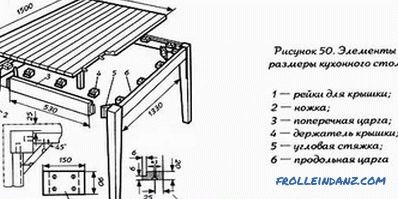

The device is a rectangular kitchen table.

The choice of materials for work

There is a variety of materials that are used to make a table with your own hands, and the choice depends only on financial possibilities and design preferences.

Chipboard is used most often for domestic needs, because it has a low price and is also easy to work with. This material has a huge color gamut, but it also has a minus in this regard - the whole gamut looks artificial, so even if you wish you can not disguise the product under an array or furniture board. Usually MDF is used, since it has averaged values. This economy option is very popular among middle class people, because the result looks quite simple, and you can use it for any purpose.

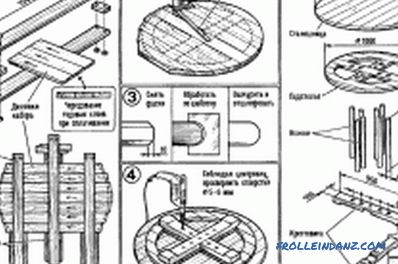

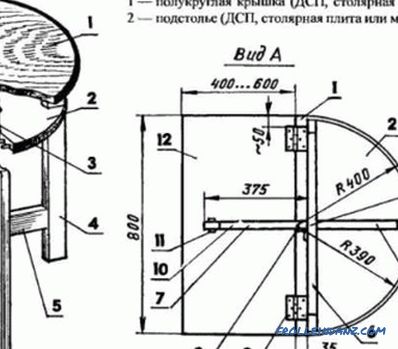

The design of the kitchen round table.

A plank made of edged boards is long and difficult, although the result is worth the effort. Financially, such a venture will cost about the same as chipboard, because the price of the material is lower, but additional investments in antiseptics, stain, varnish and brushes are needed. In addition, the probability of withdrawal is much higher. Rare use is caused by the need to process the material for a long time and carefully, and then expect a considerable amount of time.

The furniture board has a rather high price, which in practice is its only minus. It is easy to work with him, the material is very malleable, and the processing is simple. If the practice of making furniture has not yet been done, then it is better to postpone the shield for another time, since even a minor error costs financially very noticeably.

The array is the most expensive among its fellows, since no impurities were used in its manufacture. Completely environmentally friendly material, but working with it without prior experience is very difficult, because some wood species may behave unpredictably for a beginner.

A bar of medium or large section is traditionally used for the legs, and a bar is used for the shank.

Any wood, after it has been cut, is subjected to the most careful treatment, so that over time the moisture does not affect the service life. The composition dries quickly enough, but it is better to leave overnight after application.

Manufacturing work

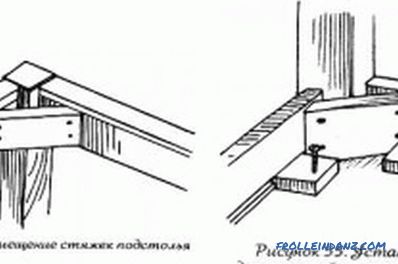

Installing the table cover holders.

Tools and materials:

- jigsaw;

- grinder;

- screwdriver and nozzles;

- tape measure;

- bar;

- bar;

- furniture panel;

- varnish and stain;

- brush flat.

First you need to figure out how the final construction will look like, after which you can start making its main elements:

- Legs (4 pcs.). In this case, 4 bars with a cross section of 75 * 75 mm are ideal, and the height depends on the preferences of the owners. If everyone in the family is tall, it is better to make 95 cm, whereas with a small or medium height, 800 mm will suffice (standard height of desktops).

- Tsarga (4 pieces). Their length depends on the future dimensions of the table, and the visible part of these parts is slightly shorter than the actual, since they will go deeper into each leg by 25-30 mm. Ideally, use a bar of 40 * 80 mm, so that the edge can be mounted to the tabletop without any fear.

- Tabletop (1 piece). Its dimensions are taken as a basis, and the legs are located in this case directly at the corners, which contributes to the ultimate stability. The optimal dimensions are 900 * 1500 mm. For such a table, it is better to use a furniture shield or cut the required number of boards.

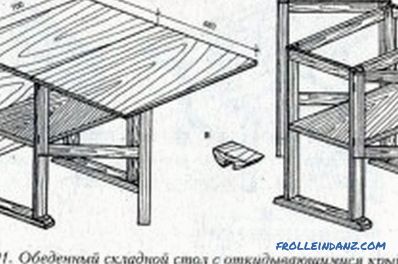

Drawing of a folding kitchen table.

After the legs are cut out of wood, holes should be made in their upper part to a depth of 25-30 mm so that there is still a thin plate of wood on top. Usually make round options, since they are easier to form nozzles on the drill with a drill.

Lugs of the same shape are formed on the tsar to fit right into the previously formed grooves. For this purpose nozzles in the form of crowns of the corresponding diameter are used.

At the joints of the tsargus and the legs, a little glue should be poured over the wood on the bottom of the holes, then the elements should be joined. If the glue was at the bottom, it will evenly disperse inside the entire area of the joint, and the excess will get out, after which they can be removed in any convenient way (most importantly, not with open skin of the hands, since the glue is slightly harmful in the liquid state).In this way, the entire support structure is formed.

Scheme of the ends of the kitchen table top.

At the very end, the table top is mounted to the legs with the help of special furniture corners. If there is a desire to provide a more reliable fixation, then you can use dowels, which are fixed between the table top and the edge of the bars. The method of their joint is identical to the method of joining the tsargi and the legs, but here you have to press the table top on top with some massive object (20-30 kg) so that everything hardened in that position overnight.

At the very end of making the table with your own hands, the entire surface should be covered with stain and varnish to give completeness in all features. It takes 36 hours to fully dry, even if the fingers do not feel stickiness after 5-6 hours, since harmful substances evaporate for a very long time.

Summing up

Before you make a quality home table, you need to get a decent tool. Cutting is carried out exclusively with an electric jigsaw, and if irregularities remain, they can easily be leveled with a grinder. Before purchasing materials, you need to carefully familiarize yourself with their structure. It is undesirable to use wood with knots, and the humidity should not exceed 20%, so as not to start playing.

The total manufacturing process can take 3-4 days, while the practical employment will be no more than 1 working day (8 hours).

The reason is the drying speed of all materials for processing.

Didn't find the answer in the article? More information on the topic:

-

How to make furniture yourself

How to make furniture yourself. What are the materials, and what is their difference? Variants of the drawings, as well as a description of the manufacture of an example. What else you need to know when deciding to do this kind of work?