Not in all cases in the house it immediately turns out to make the connection of the necessary communications. In most cases, the DHW is performed at the end of the repair or during the period when the cold season is approaching. As a rule, a boiler is often installed for this system. But as you know, during continuous operation, this device consumes a large amount of electricity. And in order to make water heating more economical, we suggest you understand how to connect it to the heating system. This will allow the water heater, during the heating period, to use the heating heat energy and only in the summer to heat the water with heating elements. Compare various techniques.

Connection to a double-circuit boiler

In order to get heated water from a double-circuit heating system to the water heater, a three-way valve is mounted. It switches the flow of coolant from the batteries to the water supply circuit coil. In such a scheme, it is important to ensure that a signal is applied to the three-way valve. There is also no need to install a recirculation pump on the coil. The main work is carried out by the heating system, which contains this device in its configuration. A recirculation pump is only required if the system includes a thermostat. As a result, when connecting a water heater to a dual-circuit heating system, you can select equipment based on your needs.

To increase the hydraulic circulating power of the heating system, a recirculation pump is mounted. Due to this, it is possible to control / adjust thermal inertia, i.e. hydraulic friction of the heating.

There are boilers with a built-in boiler, both wall-mounted and floor-standing. Such equipment is more expensive, plus you can completely get rid of excess fittings. But on the other hand, the floor has built-in water heaters up to 100 liters. This imposes obvious restrictions. Moreover, such samples cost around 60 thousand rubles. If we compare with the price of a water heater, then there is a significant difference, which varies within 4.5 thousand rubles. Given this, it is much more profitable to buy a device.

Indirect heating boiler

Let's compare several options for connecting an indirect heating water heater:

- Using a three-way valve.

- Two-pump system.

- Using the hydraulic arrow.

- Peak circulation method.

Three-way valve

At the base of this method are 2 circuits: the heating from the boiler and the heating. The three-way valve will distribute warm water between them. To control the valve is used automation (thermostat). As soon as the temperature of the water in the heater circuit reaches the set point, the automation sends a signal to the three-way valve. After this warm water enters the battery. This method is considered the most popular.

If you set the maximum temperature, it is important to foresee the extent to which the boiler heats the water. Accordingly, the temperature in the water heater circuit must be set lower than in the connected device. Otherwise, the coolant will be constantly sent to the water heater.

Two-pump system

The pumps will direct warm water to different circuits, i.e. the connection of the water heater takes place in parallel. Each line is equipped with a pump, whose operation is controlled by a thermal sensor.

A check valve is inserted into the system after each pump. This will prevent conflict between the two branches.

When the DHW is turned on, the heating temporarily stops working. Given the fact that water is heated in a water heater in a short period of time, hot water in radiators will not reach the critical temperature. If 2 boilers are used, the DHW heating and heating operation will be uninterrupted.

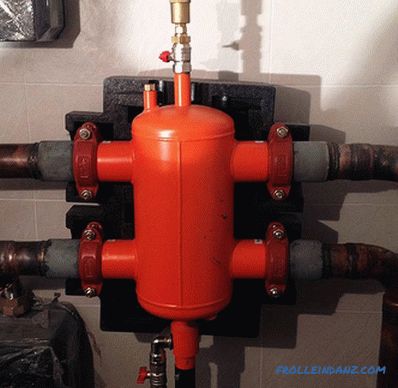

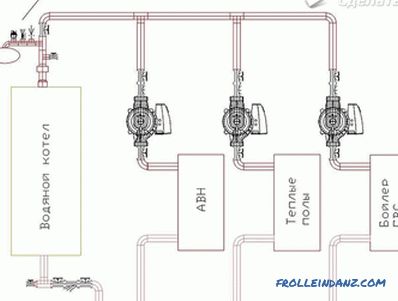

Diagram with a hydraulic arrow

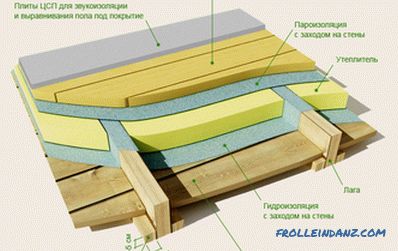

When using circulation pumps, it is important that the flows are equal. To do this, you can use the hydraulic arrow and hydraulic distributors. This is especially effective if it is necessary that the heated coolant is sent to the floor heating, boiler and radiators. To level the pressure difference in the circuits, parallel action of the hydraulic module with a hydraulic collector. Although they can not use, installing balancing taps. But in this case it will be difficult to install and adjust the system without the help of a specialist.

Return circulation method

This connection technique is only possible if there is a third input in the boiler. It will be possible to connect the coolant recirculation to it. Due to this, the process of water heating can be done very quickly. As a result, you will get rid of the problem of draining cold water from the tap until hot. This is a significant savings.

As a result, a loopback highway will be formed through which water will constantly (forcibly) circulate. You will also need to connect the following elements:

- Expansion tank. With closed taps in a hot pipeline, stable pressure will be maintained.

- Safety valve. It will protect the water heater from pressure surges.

- Automatic air vent in front of the non-return valve. This will completely avoid the airing of the pump before starting it directly.

- Check Valve. If a high pressure is in the system and, as a result, water overheats, the hot coolant will not get into the pipeline with cold water. It is installed at the entrance to the water heater.

The maximum pressure allowed in the expansion tank is not allowed above the set pressure in the safety valve.

Tools for mounting

Tools for mounting

So, we looked at the main options for connecting a indirect water heater . Let's highlight the pros and cons of this method:

Advantages:

- You can use several heating devices at the same time.

- Recyclable.

- DHW and heating flows are separated.

- High performance.

- The electrical network is significantly unloaded during the heating period.

- The inside surface of the water heater does not come in contact with running water.

Disadvantages:

- More costs are required to retool the heating system.

- The first water heating takes more than one hour.

- It is necessary to have a separate room in which all the equipment can be located.

Connection of a boiler to a single-circuit boiler

In this case, a scheme is used where 2 pumps are mounted. This will completely eliminate the use of a three-way crane. Above has been described a similar system, where the contours run in parallel. As soon as the thermostat gives a signal, the pumps leading to the tank are turned on. It is also necessary to install a check valve that prevents the mixing of the coolant.

To the gas boiler

With this connection of the water heater, the return circulation method is also used. In this case, the coolant circulates continuously under the influence of the pump. Due to this, heated water enters the faucet faster.

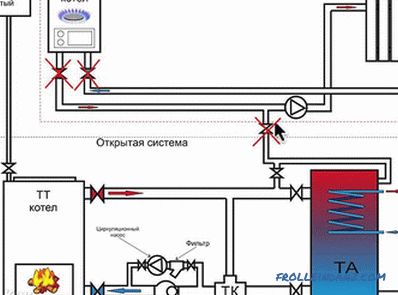

To a solid fuel boiler

In this case, it is allowed to have at the same time a system that will allow discharge of the heating medium in emergency order and the possibility of connecting the DHW. Thermostatic taps are often mounted on batteries, but be aware of the risk of overheating. If a water heater is installed, then there is no such problem, since the excess warm water will be directed to the tank. But remember that such a connection of the boiler is possible with natural circulation.

So, the following security group is necessarily mounted:

- Shut-off crane.

- Drain cock.

- Shut-off valve and check valve.

- Pump on the water heater.

- Inlet valve.

- Water heater safety group.

- Expansion tank.

Errors made during installation

When carrying out installation work it is important to avoid any errors. This can lead to unpleasant consequences. For example, it is important not only to take care of the proximity of the water heater to the boiler, but also to set the correct direction of the pipes to the pipeline for easy installation. Another common mistake is incorrect connection of the pressure pipe and the coolant inlet. Cold water is always supplied to the lower nozzle and hot water to the upper part of the water heater. There is also the risk of incorrectly connecting the pump. It is important to observe the parameters set out by the manufacturer.

So, we have considered with you possible methods of connecting the water heater to the heating system. We hope this information will be useful for you and will help you complete this task yourself. To help also provide schemes and video.

Video

The principle of operation of the indirect heating boiler is shown in the video: