Surely all the owners of private houses will agree that today, more than ever, it’s important than decorating the front of the house. Chasing the stunning exterior of the house and exclusivity, perhaps, makes no sense.

In any case, it is important to respect the middle ground and the finishing of the facade is also no exception. Without an objective assessment of the quality you should not choose budget material. Of course, carrying out these works will not be cheap anyway, however, you can choose a material that, with the same strength characteristics, will cost much less.

Literate approach to the choice of material

Front thermal panels

Front thermal panels

To make the right decision which will be profitable from the financial side, it is important to define as precisely as possible the criteria that reveal both the advantages and disadvantages of this or that material for finishing.

Pay attention to the already finished facade. Of course, the degree to which the lining is presentable depends largely on your personal preferences, which means that your own opinion cannot be objective. Consider the following parameters of the materials used:

- Resistance to visual defects and color fading.

- If you are thinking of purchasing an imitation product, then compare how similar it is to natural raw materials.

- The number of proposed textures and variations.

The facing material must be durable. It will be very unpleasant if a relatively inexpensive facade will need annual repairs. But, if the material that you like has a long service life, then you are on the right path!

You can see that it is not easy to choose front material. Having considered the pros and cons of different facing materials, you will be able to understand which material will be more reliable and durable.

Types of panels for facade cladding and their features

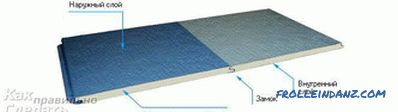

Polyplan panels

Polyplan panels

There are 2 main types of panels for finishing the facade of the house, namely:

- Polyplan panels.

- Sandwich panels.

A polyplan consists of three layers. The top layer is made of varnished aluminum. Outwardly, it resembles plaster or wood. Polyplane protects the surface of the walls of the house from steam and heat. Polyurethane foam is an internal filling of the panel that provides thermal insulation. The inner layer consists of alloyed foil and plays the same role as the first layer. Polyplan is fastened vertically with the help of special locking profiles called "Dolphin". Joints are almost invisible, which protects the walls from ingress of precipitation inside.

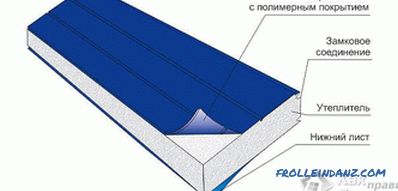

Sandwich panels

Sandwich panels

Sandwich panels are used to finish the facade, they also consist of three layers . The upper and lower layers are made of metal sheets, and between them is insulation. Details are interconnected by hot pressing. Due to this, the material is characterized by reliability, durability and durability. As insulating material in the manufacture of sandwich panels can be used foam, mineral wool, fiberglass and polyurethane foam.

When choosing a thermal insulation material, it is important to take the thermal conductivity coefficient into account, because the higher it is, the worse the material retains heat.

This facing material can be smooth, decorative profiled or regular profiled. Sandwich panels are a simple, inexpensive and quick way to finish a facade. Its small weight will not render loading on the base. Among the shortcomings worth noting the vulnerability to damage to the appearance and freezing at the joints.

Reliable stone

Wild stone

Wild stone

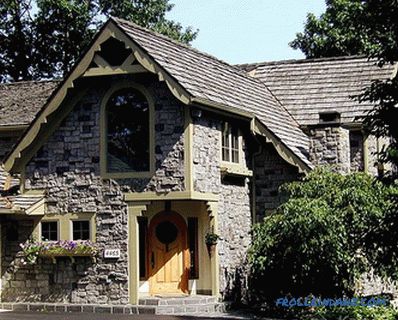

Everyone knows that stone is the strongest and most reliable material, the longevity of which can be envied. For lining can be used natural and artificial stone. Incidentally, the latter in appearance and quality is not inferior to its natural counterpart by nothing, as evidenced by the photo.

Breed, texture, size and color of a stone is a matter of taste and the choice here is simply huge. It is worth considering that the houses, the facade of which is decorated with granite or diorite look monumental and strictly. While houses decorated with travertine or marble look more natural and less severe. Whatever stone you choose, the facade of stone will look original. The frost resistance of the material in our country should be a priority, due to the severe winters that occur in our latitudes.

Natural stone is expensive, and its artificial counterpart is much cheaper. The texture, color and shape of the artificial stone is the most diverse. Material advantages: wear resistance, lightness and corrosion resistance.

Classic plaster

Facade plaster

Facade plaster

This type of finish is mainly popular from - for the low cost of decorative and cement-sand plaster.In addition, this finishing material allows you to improvise with color, pattern and texture. It increases the insulation of the house and its fire resistance. The coating dries quickly, is not afraid of water and shock. Traditionally, plaster of cement and sand is used for plastering the facade, but along with it decorative (bark beetle, lamb) and facade (acrylic, silicone) plaster are also used.

The cement-sand mixture consists, as the name implies, of cement and sand, as well as chemical additives. It copes with temperature extremes and high humidity. Acrylic plaster is the cheapest option for decorative plaster. It fits well on polystyrene foam, water resistant. With sudden temperature changes, there is a high probability that it will crack. Silicone plaster is more expensive. It is made from silicone resin. She is not afraid of direct sunlight, moisture resistant and durable. However, it is worth considering that the result of the work depends largely on the qualification of the plasterer. To cover always looked presentable, it is necessary to take care of him.

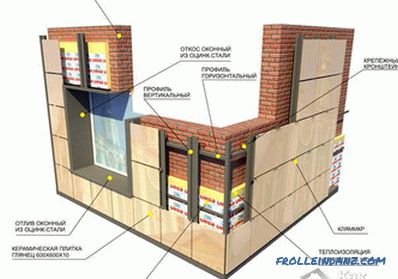

Ventilated facade

A ventilated facade is, in a nutshell, characterized as a layer cake. Between the facing material and insulation there is air space. In fact, this is a hinged structure, installed at a certain distance from the wall, which allows you to finish the facade of a wooden house in this way.

A ventilated facade allows air to pass through. Moreover, the excess moisture is discharged into the ventilated area. Rising air flows to the outside.

For the ventilated facade, different options can be used as the material for cladding. For example, it may be a low-weight aluminum composite sheet, or a heavyweight granite slab and other materials. Ventilated facades are distinguished by high energy-saving properties. They provide good noise and sound insulation. It is not necessary to trim the walls before installing the ventilated facade, while the mounted elements will hide all their irregularities and defects. If you want a modern and inexpensive veneer, then choose a ventilated facade.

Is siding good or bad?

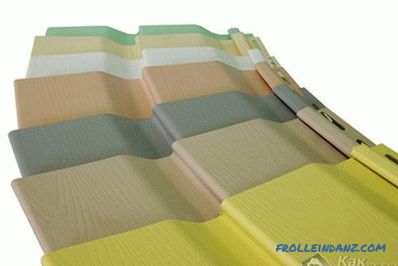

Vinyl siding

Vinyl siding

Siding, used for finishing the external walls of the house, there are two types - base and vinyl. In the arrangement of residential buildings is extremely rarely used aluminum siding. The main advantage of the material is ease of installation, safety and easy maintenance. The main drawback is that the material looks very artificial.

Although siding manufacturers claim that it can serve more than 45 years, in practice this is far from the case. In fact, it becomes brittle after frost, is prone to fading and is unstable to deformation. Unfortunately, it is often possible to see that siding loses its positive characteristics after 5 years and becomes outwardly unattractive.

If you decide to install siding during the cold season, you should consider that it has a high rate of thermal expansion.

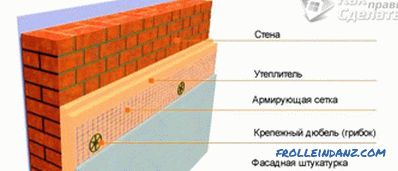

Wet facade

This is a multi-layered facade design. Each part plays an important role. It consists of 3 layers: base reinforced layer, heat insulation and decorative layer. With the help of a reinforced layer, you can even out the curvature of the walls and fix the insulating material. First, a grid is installed on the facade, to which an adhesive composition is subsequently applied. Foam polystyrene or mineral wool is most often used as thermal insulation.

Wet facade device

Wet facade device

The decorative layer is made of mineral or silicone plaster. It protects the internal components of the wet facade and externally decorates the house.

See how to glue polystyrene foam:

Front decoration with block house

Wall paneling imitating a round log is referred to as block house. The material is environmentally safe, because it is made from natural materials. A significant drawback is the high cost and comparative fragility, it is not refractory. All defects characteristic of wood may well manifest themselves at the block house.

The facade is decorated with a blockhouse

The facade is decorated with a blockhouse

Externally, the house, finished with a block house, looks very presentable. If you decide to purchase this material, then make sure that it is sufficiently dried, otherwise it may begin to rot after installation.

Since the block house is made of natural wood, it must be periodically covered with special protective compounds and opened with varnish or paint.

The better you take care of the facade, finished with a block house, the longer it will serve you.

Quality and durability of facing bricks

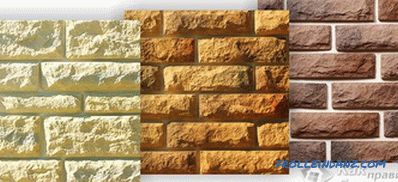

Decorative bricks

Decorative bricks

Ceramic bricks for cladding made of clay using a special technology.It is very durable, differs in good sound insulation, frost resistance and low moisture absorption. The clinker brick is fired at higher temperatures than its counterpart in ceramics. The physical characteristics of clinker bricks are also higher than those of ceramic.

The material has a large range of colors, shapes and textures. The only drawback is the possible appearance of efflorescence. But for the most part residential buildings, finished with clinker bricks, look presentable for many years. In order not to strengthen the foundation, facing the facade with a brick needs to be planned in the process of designing a house.

Advantages and disadvantages of facade tiles

It is not afraid of moisture, it is distinguished by reliability, durability and strength. If you lay the facade tiles qualitatively, it will provide a presentable appearance of the house. If the glue mortar is chosen correctly, then the facade tile will serve for more than a decade, without losing the original properties.

Clinker

Clinker

Among the shortcomings of the ceramic facade tile it is worth noting the high brittleness before installation, the need for preliminary and very thorough preparation of the surface of the external walls of the house and a straight seam.

This article has reviewed a variety of home decorating options, including those finishing materials that will cost the homeowner relatively inexpensively. The main thing is that your chosen house veneer will delight your eye for more than a decade. If you have any questions on the topic, then write comments.

Photos

Decorative bark and stone

Decorative bark and stone

plaster > Stone facade

plaster > Stone facade

Decorative brick facade

Decorative brick facade

Blockhouse and stone

Blockhouse and stone

Textured stone facing

Textured stone facing

Brick cladding

Brick cladding

Finishing with clinker tiles

Finishing with clinker tiles

Finishing with travertine

Finishing with travertine

Sandstone

Sandstone

Plastering

Plastering

Ventilated front: plank

Ventilated front: plank

Venetian plaster finish

Venetian plaster finish

Imitation ahverka

Imitation ahverka

Concrete and bricks

Concrete and bricks