Having a bath in the summer cottage or in the yard of a private house is always convenient. But in order for the steam room to function well and to please you with its warmth, it is necessary to take care of proper interior decoration. Especially if you equip a bath with your own hands. It makes no difference whether there is a sauna or a Russian steam room.

Lining in the bath will preserve the naturalness and environmental friendliness of the steam room.

If you are thinking about how to sheathe the bath from the inside, you may need the following recommendations.

To carry out the work on interior decoration, you will need the following materials and tools:

- non-coniferous wood paneling;

- wooden bars;

- insulation and metal foil;

- self-tapping screws, screwdriver, level.

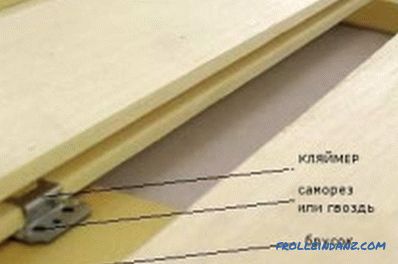

Installing the wall panel to the cleat.

First, the room must be warmed from the inside. As a heater, you can take any material that is not afraid of moisture. On a heater the metal foil fastens. Through the foil and insulation stuffed crate of wooden bars. Bars during installation must be set to the level to the walls turned out smooth.

How to sheathe the bath inside the clapboard? To do this, use only non-coniferous wood, from which the resin does not stand out at high temperatures. The best wood is birch. But you can also use linden and aspen. Lining fastened to the crate screws. To avoid burns, screws should be drowned in wood.

If it is planned to install steps in the room in order to sit on them, then under them also need to make a frame of the bars. The bars should be larger than those used for the batten. Steps are also sheathed clapboard. To protect the tree from moisture, it is recommended to fluff the linseed oil. The oil is absorbed into the wood and protects it from water.

Some important points

Popular lining profiles.

Do not fix the insulation and wood cladding directly near the place where the stove will be located. Wood may suffer from heat. It is best to decorate the walls near the stove with natural stone.

On the ceiling, the lining is made in the same way, only above the stove, instead of wood, a sheet of galvanized iron is attached.

The steam floor can be made of wood or concrete. In the second case it is necessary to lay wooden lattices on it.

For the convenience of cleaning the room, it is necessary to provide for a floor drain through which water will flow. This must be done at the initial stage of construction.

The furnace can be bought ready-made, or you can build it with your own hands from metal with a thickness of 8-10 mm or from a thick-walled metal pipe of large diameter. There are many options for how to make a homemade stove. Install the stove should be on a concrete base. If the design is homemade, made of metal, it should be lined with fireclay bricks so that the temperature in the steam room is more comfortable.

Do not install electrical wiring in the steam room. The lamp is best positioned near the entrance door. Of course, it should be designed for use in rooms with high humidity and temperature.

The door to the steam room can be hung wooden and sheathed with clapboard. The handle on the door should be wooden.

If the bath inside is properly sheathed, the desired temperature will always be maintained there, and the clapboard lining will last for a very long time without requiring any additional repairs.

Didn't find the answer in the article? More information on the topic:

-

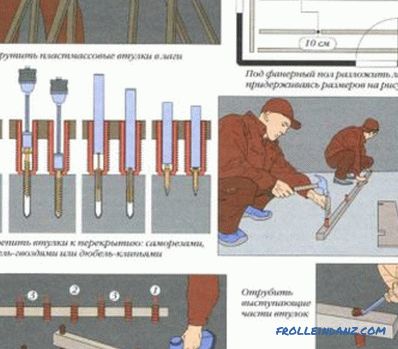

How to level the floor in a new building with your own hands?

Instructions on how to level the floor in a new building with serious drops in the horizontal surface of the base. Preparation and leveling of floors using log or cement-sand screed.