The independent production of the headset will not only save on its assembly by experts, but also get a beautiful and functional kitchen that satisfies all needs and differs little from factory-made products.

Independent production of a kitchen set will save on the call of an assembly specialist, and you will get a beautiful and functional kitchen that is not different from the factory one.

The design of the kitchen set

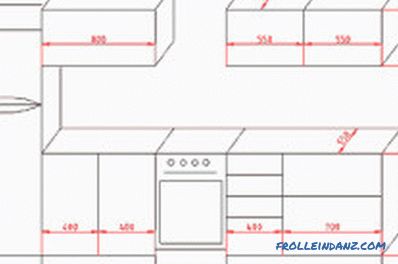

The production of kitchen furniture with your own hands begins with the design and development of the design project. If there are special computer programs, you can do it on the monitor screen or draw a diagram on paper, for convenience, using graph paper. Before making a sketch, it is necessary to remove all the exact dimensions of the place where the installation of kitchen furniture will take place, while not forgetting to take into account the irregularities of the walls, the size and location of the plinths. It is necessary to immediately determine the placement of electrical outlets, in order to transfer them to other places, if necessary, to ensure free access. The scheme should take into account the location of the stove, refrigerator and basic household appliances.

Required materials and tools for work

Before you start making furniture, you should make a project.

When the headset manufacturing project has been drawn up, it is possible on the basis of it to proceed to compiling an accurate list of the necessary materials. The front part is made of MDF, and for the internal partitions cheaper options for the material - laminated chipboard or fiberboard - are quite suitable. For the back wall, you can use plywood of average thickness, this will help to further reduce the cost of the project. Particular attention when choosing should be given to the tabletop. This part bears on itself the basic physical loads during operation and is better if it is solid, and not consist of individual pieces.

According to the compiled list, where all the individual structural elements have precisely calculated dimensions, they make an order on the basis of building materials, which provides cutting services.

Accessories and furniture edges for processing the ends of parts are also purchased there. Edging with ABS plastic edges can be ordered on site, but you need to be sure that the calculated dimensions of the parts are absolutely accurate and you do not have to make corrections by removing the excess jigsaw.

For the manufacture of furniture you will need: MDF or DF boards and fittings, as well as a set of tools: jigsaw, drill, level, screwdrivers.

Self-cutting of boards requires skill. If there is no experience in this work, it is better to use already cut pieces of the right size for making the kitchen. The list of accessories includes handles, door hinges, drawer guides and shelf fasteners. You will also need to purchase furniture fastener (confirmator) and screws for fastening small parts.

For the assembly, you need to prepare all the necessary tools:

- jigsaw;

- drill and screwdriver (can be replaced with a drill with spetsnadokami and adjustment of turns);

- tape measure, square;

- construction stapler;

- hex key;

- clamp;

- sharp knife;

- screwdriver;

- emery paper;

- household iron;

- pencil.

The process of creating furniture with your own hands

The process of creating a kitchen set: creating a project, buying material, assembling and installing in place.

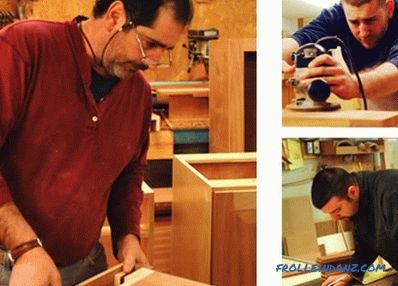

Before proceeding with the assembly, the parts must be carefully checked for compliance with the dimensions ordered, and if necessary, fit them. Next, proceed to the process of trimming, that is, using a hot iron to smooth the furniture edge to the ends of the parts, having previously placed a sheet of thick and clean paper under it. The protruding ends are cut off with a sharply sharpened knife.

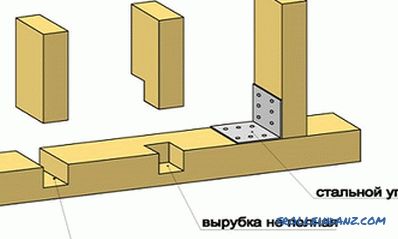

In the process of assembling the parts of the kitchen unit is connected using clamps. Under the clips is better to put a cloth or paper, so as not to damage the decorative surface. In marked places, drill holes for confirmators and screw them in without disassembling the tie rods. The back walls of plywood attach construction stapler. On the doors of the facade in the installation of hinges perform grooves. To do this, you need a special nozzle for a drill - a milling cutter. The installed hinges are fixed with screws and the door is applied to the kitchen module to determine the exact mounting location on it on the inner surface. The final adjustment of the hinges is done with a screwdriver.

Before installing in the countertop cut a hole under the sink. To do this, it is installed on the right place with the reverse side and outlined with a pencil along the contour. Then put a line repeating the outlines of the external contour, retreating from him by 1-1.5 cm.It will serve as a guide for the hole. The cutting place and the lower edge of the tabletop before installation are treated with silicone sealant.

Didn't find the answer in the article? More information on the topic: