In most cases, a well is made for the construction of an autonomous water supply at a dacha. So that she can give clean water for a long time, care should be taken to prepare the filter for the well. It will be immersed in the aquifer, so its quality must be appropriate. In this article we will explain how to make a filter for the well with your own hands.

Filter for well. What is it and what are the types?

Example of a plastic slotted filter

Example of a plastic slotted filter

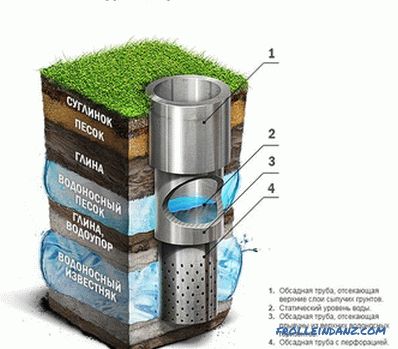

A filter for a well is an element located at the very bottom of the casing. In some cases, it is called a work site. It performs an important function of preventing the entry of soil particles into the structure, through which clean water flows to the surface. In addition, it provides additional protection against collapse. Making filters is carried out in several ways. In this article we will discuss with you the following filters that everyone can make:

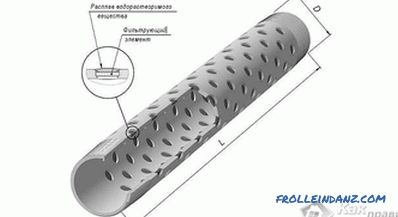

- filters with perforation,

- slotted filters,

- gravel filtration structure.

Filters with perforations

In an artesian well

In an artesian well

Speaking about perforated filters, their design is most popular. In their structure, they resemble the usual perforated pipe, which is covered with a grid. Make it yourself is easy. The most important advantage of such a filter is high efficiency. Also perforated perforated filter is applicable in a variety of rocks. It is used in most cases in the manufacture of artesian wells. The construction itself has the following components:

- filter,

- superfilter section,

- sump.

As regards the last section, large particles accumulate in the sump. It is located at the very bottom of the trunk.

Perforated

Perforated

You must first prepare the following construction material and tools:

- Steel pipe of appropriate diameter. In some cases, the use of plastic pipes is allowed, but it is important that the plastic is food grade.

- Drills for metal. The diameter of the drill should be selected according to the size of the granules that predominate in the soil.

- Power Drill.

- Metal mesh.

Grid selection can be performed by sieving sand from an aquifer. So, a grid that passes 50% of the sand will be the most suitable.

Making a filter with plastic perforations

Making a filter with plastic perforations

The filter manufacturing process itself takes place in such sequences:

- Measure the length of the sump.

- Positioning the pipe on a flat surface, mark it on it. The perforated area should be 25% of the total pipe length.

- Next, the holes are made. From the edge of the pipe one meter recedes. Between each hole should be an interval of 1-2 cm. Holes must be drilled at an angle of 30 ° -60 °. Angle direction from bottom to top.

- Every sharp edge should be carefully cleaned. Lightly knock the product so that there are no metal shavings inside and outside.

- In the next step, close the bottom of the pipe with a wooden plug.

- To prevent the holes from clogging, the pipe must be turned into a net.

So, the perforated filter for the well is ready!

Making the slotted filter

Slotted

Slotted

If in your case a rock predominates in the well that is prone to collapse, then a slot filter will be the best option. Its main feature is that it has sufficient bandwidth. On top of the product there is no deaf zone, and the area of the gap exceeds the area of the hole. To be objective, this design has one drawback. The slotted filter has a slight bending strength. For this reason, in the process of its manufacture, it is necessary to create stiffening belts that will not have perforations.

You will need the following building materials and tools:

- gas cutter,

- stainless wire Ø3 mm,

- brass mesh,

- pipe of the required diameter,

- Bulgarian,

- cutting wheel.

Production

Production

The principle of manufacturing a slotted filter is similar to the principle of manufacturing a perforated filter. The slots must be made in the zone order or in chess. The size of the gap is determined by the diameter of the granules, which predominate in the composition of the rock. As in the first case, the pipe must be wound with a brass mesh of brass weaving. Preliminarily, with the help of a grinder and a cutting wheel, make slots in the pipe. Before you lay the grid on the pipe, it is necessary to wind the wire in 2 cm increments in a spiral. It is recommended to solder the wire at a distance of 0.5 meters, which will allow you to make a rigid structure.The self-made slotted filter, made by this technology, is quite durable and has good throughput.

For better structural strength, the mesh can be soldered to the wire.

Gravel filtration facilities

Gravel

Gravel

Speaking of simplicity then this type of filter belongs to this category. At the same time, the gravel filtration construction will be no less effective than the above described filters. So, to make it, you need to take the following steps:

- The hole for the well needs to be drilled with a larger diameter.

- Next, gravel is calibrated and matched. The gravel fraction must be the same size.

- Then the well is filled with gravel, the layer of which should be 5 cm thick.

The average size of rock fractions should be less than ten times the gravel fractions.

Pebbles

Pebbles

The gravel filtration system is ready for use.

Video

Making a filter for a well: