Any lumber is produced by ripping a log. The result is the necessary for the construction and repair of bars, slats, boards of various thickness. In the construction are used only dry lumber. They have higher quality performance. For drying wood at home, a special lumber dryer can be equipped with your own hands. The construction process of this facility will take a lot of time. But as a result, the home master will always be provided with high-quality material for performing various works.

The quality of the timber depends on how dry the wood is. The humidity of the timber should be 12%.

Building a dryer

Building a simple dryer for drying small volumes of wood with your own hands in natural conditions consists of several stages:

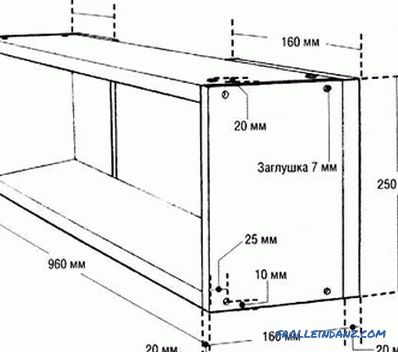

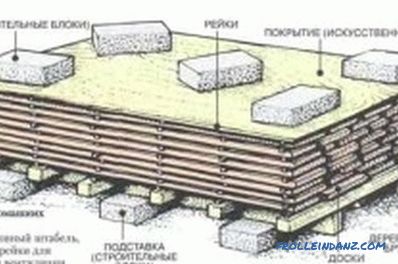

The device dryer for lumber.

- It is necessary to select and prepare an area to house the building. You can build a dryer on the house plot. For the construction of a small dryer fit a flat roof. The floor can be made of several layers of ruberoid, sprinkled with sawdust.

- The wood to be dried stacks in a pile no more than 120 cm wide. The optimal size for its width is 80 cm. Stacking height 50-70 cm. Separate layers of boards or bars are laid with slats at least 2 cm thick. Stack It is recommended to lay across the air flow in this area.

- Creates protection from rain and snow. Dry wooden bars with a section of approximately 50x50 mm are stacked on the top row of the stack. The iron is put on them, which is pressed by the same bars.

In such a dryer, the material is blown with air, the moisture gradually evaporates, and the humidity level decreases.

Drying chamber

The wood is most effectively dried in a special drying chamber. It can install automatic systems that control the entire process of drying wood of specific species. At the exit, the lumber will have a predetermined level of humidity. This camera can also be built with your own hands. But this construction will cost a lot of money. For construction you will need:

- aluminum profile;

- sheet metal;

- insulation material;

- waterproofing film;

- sawdust;

- heat construction gun.

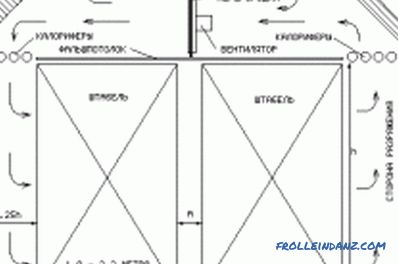

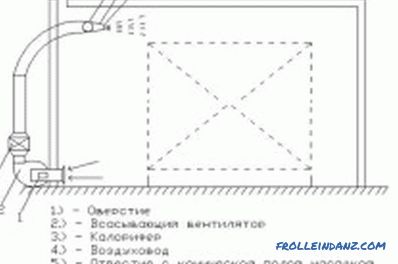

Scheme of wood drying in the drying chamber.

Construction is carried out in the following order:

- It should start with the construction of the foundation of any type. It can be piled, tape. For its construction, you can use brick, concrete, metal pipes and other materials. It all depends on the size of the camera.

- A framework is being built on the foundation. It is best to use an aluminum profile for this. He is going with the help of bolts and nuts. Other methods of joining frame elements are possible.

- The finished frame is sheathed with aluminum or steel sheets. They are fastened with screws, bolts, welding. The walls can be made of brick, concrete, other materials.

- Heat insulation is made of mineral wool 10-15 cm thick.

- The floor is covered with a waterproofing film and sawdust.

- For stacking of lumber stacks, supports of bars are prepared in the form of a kind of well. This is done in order to raise the bottom row of the stack above the floor level.

- Timber prepared for drying is stacked through wooden pads. Air must flow freely between the rows of boards. The height of the stack is limited only by the height of the ceiling.

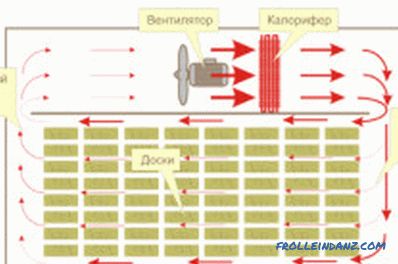

- For forced circulation of heated air, fan heaters or other heating devices are installed. The air flow should be directed across the arrangement of the boards in the stack. This contributes to a more efficient drying process.

Dryer inside the house

A small number of boards can be dried inside the house or cottage. The dryer is arranged as follows:

Drying wood at home.

- It is necessary to choose a room in which there is a fireplace or stove. Electric fireplaces and stoves can be used.

- The room is separated from the rest of the house by partitions. Installed tightly closing doors. Ventilation may be necessary for ventilation. All gaps must be sealed, since extraneous air currents and drafts adversely affect the quality of the dried material. The walls are also recommended to warm. Over insulation can be lined with brick, which is well supported by the heat from the stove and from electric heating devices. For forced circulation of warm air install fans.

- Raw lumber is stacked on specially made durable metal shelves.

Before drying, check the moisture level of the material. This is done using a moisture meter. High humidity causes early wear of buildings, mold and mildew. Overdried wood deforms due to moisture absorption and swelling. Drying wood is usually carried out to a moisture level of about 8-12%. So that it does not crack, experts recommend that the ends of the boards be treated with a mixture of drying oil and sifted chalk. According to its consistency, the mixture resembles thick sour cream.

Timber can be dried both with and without bark. Just need to remember that birch, aspen, poplar and beech in the bark can be affected by rot. In general, the drying process can last up to 2 weeks. During this time, temperature drops in the dryer cannot be allowed. There must be a fire extinguisher in the dryer room. This is required by the safety rules.

Operating modes of the drying chamber

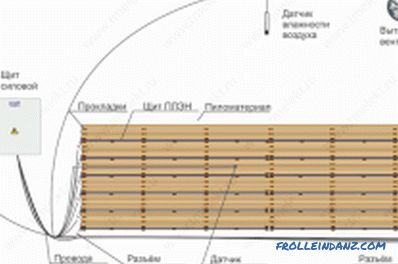

Infrared drying of wood.

The camera should not be immediately heated to a high temperature. In normal mode, it works as follows:

- For 15-20 hours, the air in the chamber is heated to approximately 45 ° C. The ventilation system is not working yet. Moisture should appear on the walls of the chamber.

- When the temperature reaches 45 ° C, one-third of the supply and exhaust ventilation systems should be opened. In about 2 days, the temperature rises to 50 ° C.

- The dampers should be fully opened and the temperature should be brought to 55 ° C. This is usually sufficient for a normal drying process. As soon as the humidity reaches about 8%, all the dampers need to be completely closed, turn off the heat. Fans continue to work during the day. After the temperature drops to 40 ° C, dry lumber should be ready to use.

Additional equipment

As an additional equipment, you can install an automatic device in the drying chamber. Its properties:

Scheme of the gas dryer.

- the system is able to work with cameras of different sizes and with different heat sources;

- costs relatively cheap;

- does not require special knowledge to maintain it;

- is easy to install;

- measures the temperature and humidity in the chamber;

- provides a fully automatic or semi-automatic mode of the drying chamber;

- automatically controls the operation of valves, dampers and fans.

For the operation of the system, it is sufficient to set the thickness and the species of timber, the desired final moisture. The system helps to dry various wood species: pine, spruce, oak, birch, beech, linden, ash, maple, alder, hornbeam, poplar, aspen, sycamore. Every 2 hours automatic equipment takes readings of humidity and temperature and makes the necessary adjustments to the work of all air heating systems and room ventilation. The approximate cost of such a system ranges from 400-450 $.

It is quite troublesome and expensive to build a dryer with your own hands.

But the result covers all costs. This is especially important for those who manufacture wooden products such as furniture and woodcarving. Dry wood is several times more expensive than raw wood. In addition, you can achieve a certain indicator of the moisture content in your own dryer. Everything can be done independently with a great desire and the availability of a suitable place.

Didn't find the answer in the article? More information on the topic:

-

The nuances of the circular saw

Circular saw device: design features, main categories. Requirements for a circular saw. The right choice of device and drives to it. Basic security measures.

-

Choosing the right home screwdriver

A few tips on what criteria you should pay attention to when choosing a screwdriver. Accumulators, shock functions, power supply voltage. What can be included.

-

How to choose the best screwdriver?

If you do not know how to choose a screwdriver, then you need to first determine your needs. For any purpose, you can choose the optimal device, if you follow the instructions for selection.