Thanks to the exterior finish, it is easy to change the architectural appearance of the house. Making the facade will allow the laying of facing bricks with their own hands. The work requires accuracy and adherence to technology, it is quite laborious, but the result will please for many years.

Types of facing bricks

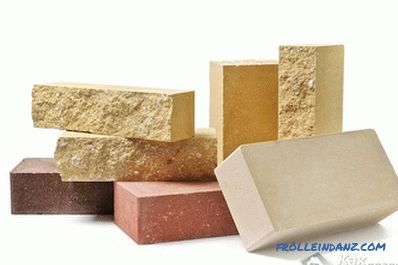

The main function of the facing material is decorative design of the house, therefore manufacturers offer a huge selection of shades and textures of the front part of the brick. The appearance and characteristics of the product are influenced by the raw materials and technology used in the production. There are several types of facing bricks.

Ceramic

Ceramic

Ceramic is a classic brick made of baked clay. Depending on the type of raw material has a reddish or white-yellow shade. The material is resistant to mechanical damage and ultraviolet, does not lose color from burning. It is made smooth and rough, with a smooth or wavy surface. The brick well passes steam, therefore in a laying the moisture does not accumulate.

Hyper pressed

Hyper pressed

The hyper pressed brick is made of shell rock or limestone with the addition of portland cement and dyes. Production is carried out by pressing under high pressure. The product is resistant to moisture and frost, its cost is lower than that of ceramics. The brick is made corpulent, hollow and figured.

The minus of the product is a smooth surface that makes adhesion to the solution difficult.

Clinker

Clinker

The clinker brick is made of plastic clay, which is burned after pressing. Bright shades of the material are obtained by adding dyes. The product is characterized by high sound and heat insulation, frost resistance, durability and durability. This material has the highest cost among facing bricks.

The low water absorption coefficient of the clinker brick increases the time required for masonry.

Features of the choice

Hollow

Hollow

All bricks for the facial finish can be divided into two groups:

- full-bodied - a material with a dense solid structure, characterized by high strength;

- hollow - a product made with holes in the body, this design reduces thermal conductivity and brick weight .

The facing material is characterized by stable geometric dimensions, inaccuracies are:

- in length - 4 mm;

- in width - 3 mm;

- height - 2 mm.

When choosing a material, you should inspect it for the presence of defects and chips. When visually assessing facing bricks, several criteria are taken into account:

- color gamut of the material;

- the quality of the front side of the product;

- the relief or smooth surface of the brick.

Recommendations for masonry

Technology

Technology

To achieve maximum quality masonry, you need to know the basic rules:

- How to start work? First of all, laying without mortar is performed to determine the amount of brick to be cut.

- The material is cut by a grinder, a disc is used for stone. Disc work on metal and hammer is prohibited.

- Masonry mortar is made from 1 part cement, 3 parts sand, 1 part water. Sand before mixing is sieved. The consistency of the mortar should be sufficiently thick, the brick should lie tightly. Color pigments are added to give the mixture a shade similar to brick. Pottery soaked before masonry.

- The size of a horizontal seam should not exceed 10 mm, vertical - 12 mm.

- If the face is contaminated with a solution, it is immediately removed with a trowel. Every 4 rows, facing brick masonry is wiped with a damp cloth to get rid of any residual dirt.

- To ensure the ventilation of the masonry, three vertical joints are counted and the fourth one is not filled with mortar.

- Facing the building is carried out at a temperature of + 5ºC.

Tools and equipment

- Concrete Mixer.

- Buckets for solution.

- Scaffolding.

- Trowel.

- Plummet and level.

- Hammer.

Mounting technology

Alignment

Alignment

Having determined the location during the dry unfolding trimming bricks and window and door openings, proceed to leveling the level of the cap. The first row of brick fits on it around the perimeter of the building. The solution is applied indented by 1.5 cm from the edge. After the first row, corner columns are formed to a height of 4-6 rows. Between the elements the thread is stretched over which the bricks of the remaining rows are being laid. This guideline helps to keep horizontal. To tie the cladding to the main wall, use an anchor with wire attached to it.

Making seams

Making seams

After the mortar is set, sew the seams with a special tool. In the process of work it is necessary to monitor the cleanliness of the front of the brick and wipe it.

Brick cladding gives the house a respectable and attractive look, and independent work allows you to save on the services of craftsmen.

Video

The technology for laying bricks can be seen in the following video: