Although this device is called a building hairdryer, it is not intended for drying hair; it is too powerful for that. But to weld linoleum, solder, melt soft tiles and cut roofing felt a good heat gun knows how to cheer. In this article we will tell you how to choose a building dryer, which will be a great help for a home wizard.

What is a building hairdryer for and what kinds of work can it be done with the help of a

There are a lot of works that a building hairdryer can perform. In particular, he:

# 1. It will dry the glue, putty, tile or stucco joints, joints of the material before laying the insulation.

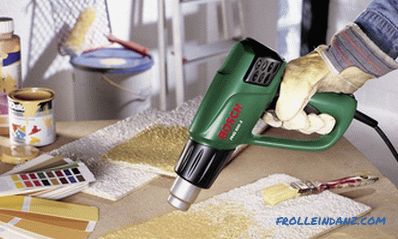

# 2. Removes varnish or paint, veneer or wallpaper, tile or parquet from windows, floor and furniture. To do this, use hot air and trowel-scraper.

# 3. Form polyvinyl chloride and polystyrene products (at 300 degrees). Well, at 500 degrees you can work with acrylic, and with plexiglass. The construction dryer with pipes and rods made of polyurethane perfectly copes.

# 4. It will freeze icy drains, pipes, locks, remove ice from steps and wires.

# 5. Disinfects wood by killing bugs and microorganisms, destroying anthills built into a stone wall or pavement.

# 6. Sticks together large parts with contact glue, increasing the holding period and heating the joints. In addition, a construction dryer will help accelerate the adhesion of two-component adhesives, remove PVC stickers, and unscrew the screw attached to the adhesive.

# 7. It will press and hot-melt polyvinyl chloride pipes, give the handles and hoses the necessary shrinkage.

# 8. Weld overlapping pieces of PVC film, tarpaulin. Pieces of PVC flooring thermohair dryer connected welding rod. Having melted bitumen, it is possible to repair the roof with the help of a thermogun, and cut the bituminous cardboard and roofing material or weld.

# 9. Solders pipes using tin or silver solder. For the latter need a temperature not lower than 400 degrees. Copper water pipes, wires and cable lugs can be easily soldered (or unsoldered) with a building dryer.

As you can see, the scope of use of a hot air gun is quite extensive, so it is extremely useful to have such a tool in the household. Now consider what its properties and characteristics you need to pay attention to when buying.

Photos of various types of work that can be performed using a heat gun.

Specifications that need to be considered when choosing a construction hair dryer

In general, all the models of industrial hair dryers are almost the same constructively. The ceramic insulator together with the heating element (spiral) located on it is in a durable plastic case resistant to high temperatures. There is also an electric motor with one or two impellers operating at high speeds. Its task is to disperse the air heated by the spiral to the nozzle, where it begins to work, falling on the guided surfaces. Next, we consider the main technical parameters of the device that must be considered when choosing it.

The device of the building hair dryer.

The maximum temperature of the air jet, performance, power

The maximum allowable temperature when working on most models will be 600 or 650 degrees. Although there are also very powerful specimens, in which this parameter reaches 750 or 800 degrees.

The amount of air passed through a heat gun per unit of time determines its performance. For middle-class models, this value ranges from 200 to 650 liters per minute. This parameter is directly related to the heating temperature. With increasing performance and temperature of heating, the device will have more opportunities. Its power, made up of the power of the spiral and the fan, will also increase. Power varies from 500 to 2500 watts. If it is more than 2000 watts, get ready for the fact that the device will be overall, heavy and expensive. so if you choose a device for home use, then look at models with power up to 2000 watts.

Adjustment of forced air volume

An important indicator is the adjustment of the volume of forced air. Such adjustment is not available in all models, but it can be extremely useful if overheating of the entire surface from which work is performed is not desirable or the part being processed is very light and can simply be deflated by air flow.

Hair dryer with the ability to adjust the amount of forced air.

Adjusting the heating temperature

The ability to control the temperature is an important parameter. It gives the master the opportunity to adapt the device to work with various materials.If the hair dryer has a class of "hobby", then this adjustment will be a step type (there are 2 or 3 fixed values).

A building dryer with stepwise adjustment of the charge air temperature.

In professional models, the adjustment is more interesting - smooth. They are subject to any material, even very difficult to handle. The adjustment method can be electronic or slider.

Smooth adjustment of air temperature.

Electronic system for maintaining a given temperature

The system for maintaining a certain temperature (otherwise, stabilizing the heat flux) is performed on an electronic circuit. It allows you to maintain a constant temperature of outgoing air and saves the heating coil from premature wear. As a rule, such devices have built-in memory, which remembers the temperature until the next power-up. It is more comfortable and faster to work with such devices, but these are usually professional models that are expensive. Therefore, if you choose homework tools, this is not your option.

Cold air blowing

The presence of cold air is a considerable plus. By cooling, for example, with cool air, the place where plastic pipes are sealed, it is possible to reduce the total work time. After all, wait until the hot place cools down by itself, do not have to. Depending on the model and manufacturer, this is constructively carried out in two ways: by turning off the helix or by having a second nozzle. The second method is more modern and "advanced", but the first method allows you to quickly cool the spiral after work by packing the device. In addition, the presence in the device of the second cold-blown nozzle allows you to glue together thermoplastic materials when the first nozzle warms up and the second immediately cools the glued surface.

Availability of a filter for incoming air

A filter for incoming air is good when the device is supposed to be used often where there is a lot of building dust. She, getting inside the construction fen with the air, can very quickly disable the spiral. If the air passes through an easily removable filter, then this problem will not happen.

The presence of the control display

When performing delicate work, overheating or insufficient heating of the workpiece can spoil the part. In this case, it is required to continuously monitor the temperature of the air flow. The control display can be made using a small screen, as well as using LED backlighting.

Overheating Protection

The Thermostat function turns off the thermoelement when overheating. And this can happen when the technical dryer is running perpendicular to the surface of the material. Air flow first goes to the treated surface, and then repels from it, finding itself on a spiral. This leads to overheating.

Thermal protection cover

The casing for thermal protection is located on the pipe through which air enters the device. It can be either removable or fixed type. In the first case, this cover can be removed in some situations. For example, to get to any gap. At the same time, it is necessary to work carefully so as not to get burns and not to damage the material. The body of the building hair dryer is always made of a material with heat insulating properties.

The shape of the handle and its type

Mostly the handles of these instruments are in the shape of a pistol. However, this is inconvenient if the use of a building dryer implies working in a hard-to-reach place. And then it is better to use a cylindrical handle straight shape. There are also models with a rotary handle. It is good when there are anti-slip pads on the handle. Also the handle can be open and closed. The second option is preferable, since it protects the worker from hot particles and hot air.

A heat gun with an open handle in the shape of a gun.

A closed handle for protection against hot air.

Technical hair dryer with a round handle that can be installed at any angle.

The rotary knob allows you to work in hard-to-reach places.

Parking methods

This device is sufficiently “gentle” - when it falls, the ceramic element often breaks or the spiral breaks. While taking a break, you will not put a vertical hair dryer on it, and you will not put it sideways - this is a problem. Therefore, it is good when there is a loop on the power cord that allows you to hang the device on a hook or nail. There are other options - sometimes supports and hooks are made on the body of the thermogun. Then it can be installed on any flat base.

About weight, dimensions, power cord

Typically, such devices weigh from 500 g to 1 kg. You should not take a lighter device, as this may affect the quality of the body and handle. And the power will be too low - not enough for a good job.The cord coming from the network, you need a three-meter, not less.

We select the configuration option

The nozzles attached to the building hairdryer are called nozzles, nozzles or nozzles. Basically they are cheap, and if necessary, you can always buy the necessary one. Here is a list of basic tips.

# 1. Round focusing nozzles are needed for working with copper pipes and welding tape.

# 2. Flat nozzles remove old paint, varnish, wallpaper, distort plastic sheets.

# 3. A reflex nozzle with a frontal rounded outlet is used to bend polymer pipes.

# 4. Slotted nozzles will weld overlapping PVC pieces.

# 5. The cutting nozzle has the form of a flattened tube, they cut out the foam.

# 6. Side nozzles (with glass protection) will help to clean the window frame without heating the glass itself.

# 7. Plastic mirrored nozzles are welded.

Species of nozzles on the technical hair dryer.

Another thermogun can be equipped with extension handles, scrapers and rollers, welding rods and adapters (for attaching thin nozzles). All this fits into the suitcase. Not bad, if it is made of metal - because such devices are very fragile.

Final choice: generalization and a couple of tips

When deciding which hair dryer to choose, you need to clearly know what the device will be used for. Construction hair dryers, as well as any other tools can be divided into two categories, these are household and professional.

Amateur technical hairdryer is suitable if:

- the uninterrupted work time that you need does not exceed 15 minutes;

- the required maximum air heating temperature does not exceed 560 0 C;

- there is no need for a smooth temperature adjustment.

The main thing here is that the brand is reliable. Good devices from Bosch and Makita, AEG, Steinel and Skill, Metabo, Kress, Sparki, DeWalt, Black. Decker.

A professional building dryer is necessary if you need:

- a function of smooth temperature control;

- an electronic function of temperature stabilization;

- the presence of a removable heat shield;

- the presence of a closed handle.

As for manufacturers, in this market segment such manufacturers as Bosch, DeWALT, Makita, Metabo, Steinel have shown themselves best of all.

Operating Tips

# 1. To prevent the thermoelement from failing, direct the air at a 45 degree angle. According to some data, 95% of all breakdowns of building dryers occur due to their overheating, therefore it is important to use this tool correctly.

# 2. Do not work near flammable, flammable liquids.

# 3. Ensure that the instrument and the processing surface do not overheat. But do not check the air temperature with your hand - you will get a burn.

# 4. After work, allow the heat gun to cool down - do not touch its work surfaces. Note that on a very hot day, the details of the device can cool for a long time.

# 5. Remove paint or varnish only with a scraper (included), and wear a respirator.

# 6. Work better outside or in a well-ventilated area.

# 7. Without technical supervision, the included technical hairdryer cannot be left.

Video: How to choose a technical dryer