The overlaps on the wooden beams connect the floor of the building with the attic room, basement or upper floor. The design serves to evenly distribute the loads on the walls of the building and is the basis for a rough floor covering of the upper room and covering the lower ceiling.

Overlapping on the wooden beams is necessary for even distribution of loads on the building.

The device of overlappings using wood beams makes it possible to do without lifting equipment and make installation by a brigade of 3-4 people. The speed of installation of supporting structures of this type is higher than when using other materials. Overlappings on wooden beams are more often mounted in single-storey houses of the private sector, frame constructions.

Types and characteristics of overlaps on wooden beams

Overlaps with timber bearing elements may differ:

- design features;

- bearing material, enclosing elements and thermal insulation;

- by fastening connections.

Floor beams are made of timber or logs hewn from one or 3 sides.

Floor beams are made from a bar of calculated section, edged boards, logs, hewn from one or 3 sides. Recently, the use of glued laminated timber having standard dimensions and regular geometric shape has become common. This version of the manufacture of bearing elements is considered the most reliable.

Glued bearing elements are made to order, and they do not have to be brought to the desired dimensions. I-beams are also used with a combination of wood and OSB. For the equipment of floors used beams from hardwood and softwood. They are pre-dried for at least 3 months. To increase the strength, additional layers of plywood, OSB or particleboard from 12 mm thick are nailed to them. In places where the beams are laid on the inner walls, the joint is reinforced with clamps, brackets or planks with a thickness of 40 mm or more.

The overlap between the floor and the attic room can be either an independent structure or an element of the roof frame. In the latter version, the trusses rest on the beams. The combination of the roofing system and the ceiling reduces installation costs, but repairing the structure is more difficult to carry out. In addition, it has the worst sound insulation properties. When installing the basement flooring should be carried out reliable waterproofing.

Principles for calculating overlap elements

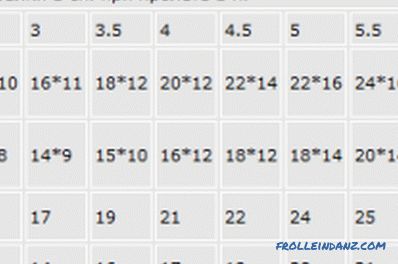

Auxiliary table for calculating the number of beams.

The interval between the beams, their length and section dimensions are selected in accordance with the parameters of the overlapped area. Taking into account the maximum load during operation, the type of insulation plates, the weight of the ceiling finish. The dimensions of the beams can be increased due to the design features of the premises. For interfloor structures, the load from equipment, furniture and people is taken into account.

Bearing elements must withstand a load of 200 kg / m 2 considering their own weight. Based on the design of the structure, the cross-section and spacing of the beams are calculated. Allowable deflection from the specified load is for the basement floors - 1/250 of the beam length, for the attic - 1/200. The limitation on the length of bearing parts for interfloor overlaps is 5 m, for garret - 6 m. The optimum ratio of height to width of the cross section of a rectangular element is 7: 5, to the length of the beam - 1:24.

Beams from logs are able to withstand heavy loads than cant, but with increased deflection. The fastening of paired bars with bolts increases resistance to loads by 2 times compared with non-fastened elements. To determine the exact parameters of the supporting structure, you can use online calculators or special tables.

Laying and fastening of beams

After the measurements, the workpieces are sawn at an angle of 60 °. Side view of the beam must have trapezoidal contours. This shape of the ends contributes to a better evaporation of moisture from the wood structure. The day before installation, the beams are impregnated with antiseptic and flame retardant compounds. The ends of the elements are not processed. The side surfaces of the edges of the timber, exposed to the seat, are coated with resin and wrapped with roofing felt.

Tools for laying floor beams.

For the installation of the floor structure, tools and additional materials are required.

- jigsaw and wood saw;

- ax, hammer;

- hydraulic level;

- tape measure, fishing line;

- keys, screwdriver;

- nails, screws, anchor bolts;

- brackets, corners;

- roofing material, heat insulation material;

- strong rope;

- construction goats, ladder.

First, set the extreme beams with the exposure level.Wooden linings, previously coated with waterproofing mastic, are placed under the ends for leveling. Every third mounted beam is fixed with anchors.

In the opening, the beam should be made at least 20 cm. From the wall, the end should retreat 5-8 cm. Approximately at the same distance, the outer beams should be exposed from parallel walls. In this space is attached rake, separated from the bearing part of the roofing material. From the extreme elements of the line stretched, on them exhibited the remaining beams. After adjusting the position of the beams, the landing slots are filled with a solution.

When laying on log walls, the beam is placed in the groove of the upper rim with preliminary laying of the waterproofing material. If the installation requires the hemming of the ends of the beam, it can be done not more than 1/4 of the element height.

Formation of the inter-beam space

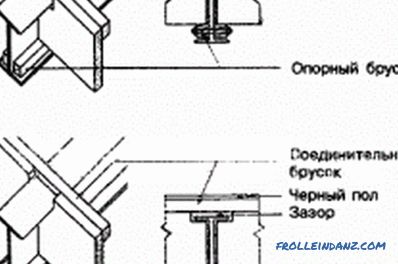

Mounting scheme of wooden floor beams.

In addition to the supporting elements, the structure of the ceiling includes a roll, an insulating layer, the floor of the upper room and the ceiling trim of the lower one. In order to roll forward, cranial bars (5x5 cm) are fastened to the beams, on which boards or panels are laid. You can use the croaker.

Some types of ceiling decoration require a flat surface. In these cases, along the ends of the run-up boards lying on the cranial bars, a quarter is sampled (fold). Rollout is covered with roofing felt, it can be made with clay mud and mud to the middle of the height of the opening.

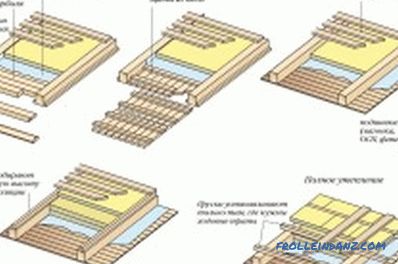

The openings are filled with various noise- hydro- and heat insulating materials. Mineral wool is often used as a heat insulator, sometimes foam plastic, polystyrene foam, etc. It can be filled with bulk materials (slag, sawdust, etc.) 3/4 of the height of the opening.

The thickness of the heat-insulating layer can be from 5 to 25 cm and depends on the purpose of the ceiling (attic, basement) and climatic conditions. Many experts do not recommend heat insulation slag or expanded clay. With modern standards of thermal insulation bulk coating will have too much weight.

So that the moisture does not penetrate into the insulation, a waterproofing film is attached before fixing the ceiling of the basement and arranging the floor of the attic.

Insulating material in the structure of interfloor overlap mainly performs noise absorbing functions. In order to reduce the penetration of sounds to the lower floor while moving on the upper floor, its ceiling is attached to additional beams that are not directly connected with the main carriers.

The device of the floor of the upper floor

The scheme of thermal insulation of the floor of the second floor over wooden beams.

After the installation and installation of thermal insulation material, a reinforcing mesh is applied and a cement mortar is applied. The concrete surface will serve as a subfloor. For the attic floor, you can install transverse logs on the beams and sheathe the floor with a tongue-and-groove board.

Installation of the floor can be done directly on the wooden beams or on the logs that are pre-fixed to them. The first method of the device of floors differs in the best durability of a design since the beams rigidly lean on the bearing walls.

It is easier to carry out the work on the flooring of the lagging, and this floor structure increases noise absorption by several times and contributes to better ventilation of the wood. Noise isolation increases with the device "floating" floor. The design is not fixed rigidly in the walls, which also increases protection against the spread of sounds.

The flooring can be made of chipboard or planed flooring, parquet, laminate or linoleum can be used as a finish. The ceiling under the ceiling is finished with sheets of dry plaster or plastered on the face.

The cost of the arrangement of floors can be 15-20% of the cost of installation of all basic structures of the structure. The cost of the work is about a quarter of the cost of the required materials. Therefore, the use of wooden beams as bearing elements and independent arrangement of the floor will help to significantly reduce construction costs.

Didn't find the answer in the article? More information on the topic: