Rafter systems are the main supporting structure and roof frame. Their design depends on many individual factors, among which were the rafters. Among the existing options the most popular were and remain rafters of uneven bars. They are eco-friendly, easy to install and fit.

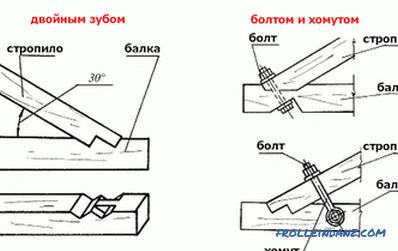

Connection rafters.

Types of truss systems

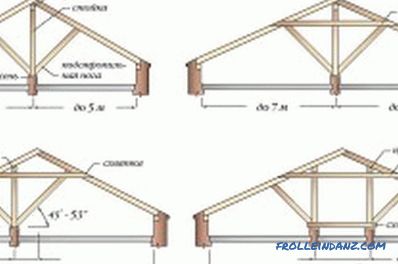

Truss systems are built according to the shape of the most rigid figure - the triangle. The choice of construction is influenced by the type of roof, the length of the runs, the actual loads, the presence and location of the supports. Modern architectural delights often require sophisticated roof systems with complex trusses and multiple beams. But if we talk about basic concepts, then in construction there are two types of truss systems used:

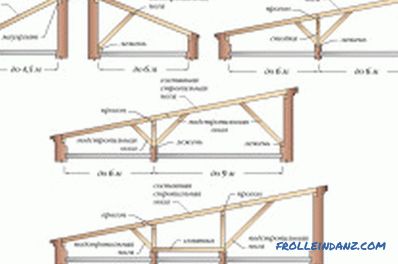

- slanting (with the ends resting on a binding bar, and in the middle - on the inner wall of the building or intermediate supports);

- Hanging (based solely on the Mauerlat).

Typical types of truss systems used.

Visual schemes help you understand the systems best. The choice in favor of a particular type is determined by the peculiarities of the future roofing.

Suspended rafters are installed if there is a wall between them or the supports are centrally located relative to the bearing walls of the building . The run between the supports should not exceed 6 m. The system allows the rafters to bend, as with beams, the design is very easy.

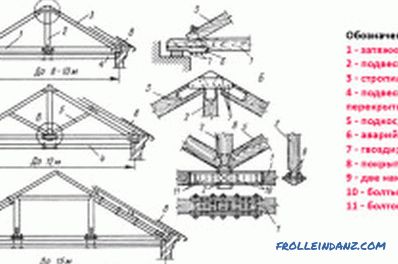

Hanging truss systems are used to block large spans where there are no buffer supports. The system works in bending and compression. It also gives a strong horizontal arching force, which is regulated by tightening (it connects the rafter legs with it).

Often, puffs are installed at the base of the rafters, so that the structure plays the role of a beam for the ceiling and allows you to make an attic. If this is not necessary, the tightening can be set higher. Keep in mind that with an increase in the installation level, the density of the puff itself increases (the higher it is set, the stronger it should be).

Truss systems can be alternated. Where there are supports, lay rafters slit, and where there is not - a hanging system is used. In most cases, the rafters are installed across the long side of the house, because of which the span is rarely more than 6 m. Otherwise, the system is supplemented with auxiliary elements. To clarify all the nuances, it is better to entrust the design and selection of the type of rafters to professionals.

Required calculations

Calculation of the truss system for a dual-pitch roof.

Any construction always begins with design and calculations. In this regard, the development of the system of rafters is a complex and time-consuming process, because the roof should not only provide protection from external factors and save heat, but also withstand a lot of loads, which is why calculations of building rafters cannot be done offhand.

All effective floor loads are divided into two categories. Permanent loads imply weight:

- rafters and other elements of the truss;

- roofing;

- waterproofing materials;

- battens and counter grilles;

- engineering systems, snegozaderzhateley;

- other types of equipment and devices installed on the roof.

A: variable loads should be understood as the mass:

- snow;

- the maintenance personnel of the roof itself and the systems installed on it;

- exposure to wind;

- exposure to seismic activity.

In the calculations, we take the maximum weight of all the elements that exert a load on one square meter of overlap. If this is not possible, then the mass of each individual element is taken into account.

Particular attention should be paid to the weight of wood and the type of rafters system; these two factors directly affect the specifics of the calculations.

Fixing units for the truss system.

Making a competent calculation of all the necessary data, taking into account the various nuances of a simple man in the street can be very difficult. Considering the above, it is better to entrust this matter to qualified design engineers.

If you decide to do everything yourself, you can apply a special formula to calculate the snow pressure on the roof:

S = Sg * µ,

where Sg is the mass of snow per m 2 of the horizontal surface, µ is the coefficient for calculating the pressure on the inclined surface.

The value of µ with a slope less than 25 ° = 1, up to 60 ° = 0.7. In cases where the angle is greater than 60 °, the effect of snow cover is not taken into account.

As in the case of snow, there is a formula for calculating the impact of wind:

Wm = Wo * K * C,

where Wo is the value of wind pressure, C is aerodynamic coefficient, K - factor accounting for changes in wind pressure relative to altitude.

rafters of a shed roof.

With a roof slope of less than 30 °, the wind tends to knock it down, and with a slope of more than 30 °, lift it.

The calculation of the mass of the roof depends on the characteristics of the building materials, and the calculation of the weight of the truss depends on the type of roof chosen.

The load on the linear meter of a rafter foot can be determined using the formula:

Qr = A * Q,

where A is the distance between the rafters, Q is the total pressure per m 2 overlap.

The calculation of the maximum length of the working section of the leg and the minimum cross-section of the beam has many nuances and is performed according to special tables, taking into account the inclination of the roof, the resistance and the type of materials used.

In view of the many nuances, it is better for specialists to entrust the calculation of wind loads. Professional calculation will help avoid operational problems, save your nerves and money.

Preparation and tools

The design of the roof system of a sloping roof.

Before the start of construction work, you need to purchase all the necessary materials. Their quality will determine how long the finished truss system will last. Take your choice responsibly. The rafters system consists of a mauerlat, main beam, shalevka and auxiliary materials.

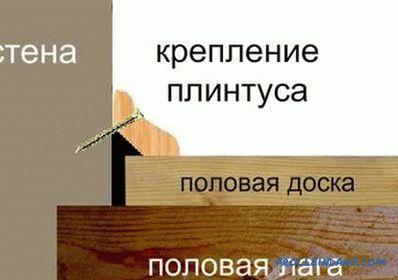

The Mauerlat (harness) is the foundation upon which the rafter legs rest. The objective of this design is to evenly distribute the mass of the roof on the upper part of the walls of the building.

For a classic dual-slope roof, a timber-mauerlat may be 100x100 or 150x150. But the size of the section and the length of the main bars is selected individually, based on the characteristics of each individual design. So, there are no universal sizes, there is a minimum and a maximum, which are equal to 100x50 and 200x200, respectively. However, it is not recommended to use them when building a residential house. The most commonly used bars are 50x150 or 80x180. The choice in their favor is explained by the fact that these options are strong enough and can withstand serious loads. At the same time, they do not overload the house.

The purchase of materials is completed by the selection of edged boards (shalevki), which are nailed across the rafters to form the plane of the slope, and additional materials.

Scheme of rafters.

Raising systems, created by hand, require special attention to the materials used. Their humidity should be 18-22%, and the timber itself should be made of softwood (preferably pine or larch) without defects. In addition, we must not forget about the preliminary antiseptic, biological and fire-resistant processing, good drying of all wooden structural elements. It is on these factors that the duration of operation and the quality of the rafters depend. A system of poorly dried materials tends to warp.

Preparing the box will help create a single template and size for assembling the base of the roof. The goal is achieved by aligning the walls and eliminating all differences in their sizes. For alignment of walls of brick, block or stone houses screeds made of sand-cement mortar are suitable. In constructions made of wood used different lining.

The necessary equipment for work must be of high quality, but not necessarily professional. What is important here is not the brand, but the completeness, reliability and completeness of the set, which will ensure simple and quick installation.

Tools needed for work: Bulgarian, plumb, construction level, drill, handsaw, tape measure, pencil.

To assemble the rafters, you will need:

- a pencil or a marker for marking;

- a tape measure (nominal is not less than the longest span);

- construction level;

- plumb;

- hammer (preferably several, of different weight and type);

- nail-catcher;

- ax;

- hacksaw;

- Bulgarian;

- saw (or chainsaw);

- drill with a set of drills;

- countersink for a drill;

- knife;

- mounting elements (screws, clamps, etc.).

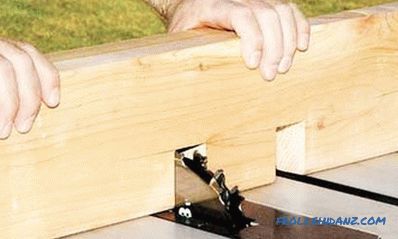

In addition to the "official" devices, home-made tools are often used, which greatly facilitate the process of assembling and installing the frame. For example, auxiliary templates are used to cut corners, control the distance between parts of a structure and collect sections of rafters.

The so-called barb will help facilitate vertical installation of the truss system. The fixture is made from a cut of a bar with a section of 6 to 6. On both sides of it, a corner of 40x40 is stuffed onto it. The ends of the corner are cut to get two sharp stops that prevent slipping and provide a safe lifting of the frame.

Insurance is also used to lift the structure. The unit is assembled from a cable, a lift and a hoist, it is used to adjust the length of the release, as well as to prevent the system from tipping over.

Assembly options

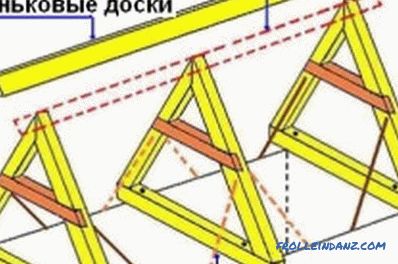

Key elements of hanging trusses.

Before assembling the rafters, you should be familiar with the type of mounting. It depends on the type of building. For wooden houses, use is made of a joint with upper crowns, of stone - with supporting bars. When installed on frame buildings, the system is fastened by means of a junction with a top trim.

There are only two options for assembling: assembling a roof truss on the ground and assembling directly on the roof.

The first option is suitable for lightweight frames and involves lifting the finished structure to the roof of the house. The second is used in order to assemble massive structures, which will be difficult to lift off the shelf without a crane.

A universal instruction that would fit under any construction project simply does not exist. Therefore, even if a complex rafter system is not intended, it is better to resort to the help of specialists.