Sawdust as a heater is waste after woodworking in the form of the smallest wood dust and chips. This recognizable material is used as a heat insulator for many years, because it is able to keep heat for a long time, emitting wood resins, which makes the material an ideal filler. The use of sawdust, providing warming of the attic, ceiling, roof, is ideal because they can serve for a very long time, ensuring a high level of thermal insulation.

It should be remembered that sawdust is a habitat for mice or other pests.

In which area chips are used

Low-rise construction is the main area of application for chips. Sawdust as a heater was always added to the clay in order to construct special ceilings for rural houses from this composition.

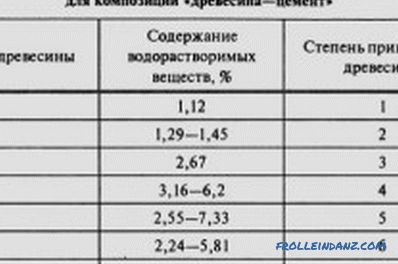

The thermal conductivity graph of opil.

If we use this technology to insulate the roof of sawdust as a basis, then today the industry produces already modern building materials. They include wood concrete, concrete with sawdust, wood blocks, which provide a reliable layer of thermal insulation.

In the use of sawdust in the construction process, developers of private houses are interested in the insulation of the roof, walls, ceiling, floor, attic with sawdust. It is possible to use sawdust as a heater in different directions due to their low cost. Roof, interfloor overlap, attic, ceiling, floor and wall structures, attic are insulated with various building materials. A solution of cement, chips and gypsum can be used to insulate the elements of the building, attic, which allows you to save money.

Why sawdust is subjected to processing

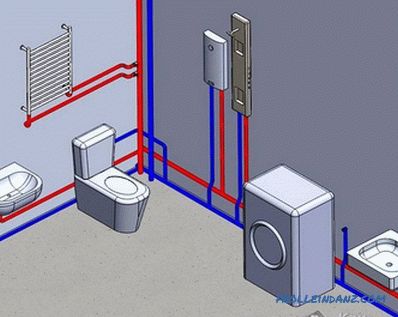

Floor insulation with sawdust.

To provide thermal insulation, use sawdust, which are pre-prepared in a certain way. If disinfection is not carried out when processing sawdust, then this material acquires two major drawbacks, becoming:

- Flammable.

- A habitat for mice or other pests.

Before working with sawdust, they should be mixed with the composition of lime, cement or gypsum, wetting with a special substance, that is, antiseptic. The prepared mixture will have fire safety and provide protection from pests. If you start building a frame house and attic or roof insulation using raw sawdust, this can have negative consequences.

Because of the ill-considered use of fire, a timber-frame house may burn out. Therefore, before the construction necessarily be carefully weigh everything. Sawdust can be replaced with other insulating materials, for example, ecowool, which also has its drawbacks. Any shortcomings are leveled by competent implementation of the material used.

Use of sawdust for the purpose of self-warming

The use of sawdust for home insulation

Often you can use chips with the purpose of the insulation of single-storey buildings. If you plan to collect heat insulator from sawdust yourself, then you should prepare the following types of materials and tools:

- Cement.

- Lime.

- Sawdust.

- Spade.

- Mixer.

- Antiseptic.

The thermal insulation layer can have a thickness, the size of which is determined by two factors:

- The conditions of the area.

- Multifunctional purpose of heat-insulated premises. A heat insulator with a width of 25 cm will be sufficient to install floor slabs up to 15 cm wide for walls.

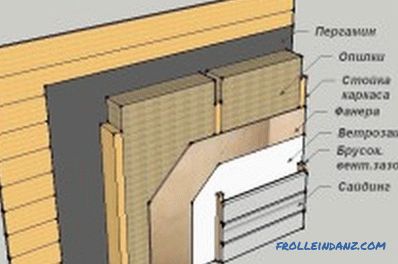

For this purpose, a special stand is mounted on the main frame, which creates space for filling it with sawdust.

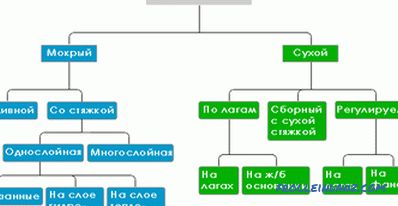

Scheme of wall insulation with sawdust.

In order to properly perform insulation using sawdust, you need to know the following points:

- Be sure to take into account the presence of objects at risk of inflammability, which include sockets, wiring, switches, insulated using material unable to ignite.

- Connect the electrical wiring and the chimney pipe.

- Electrical wires are usually hidden in steel pipes 3 mm thick.

In order for cement to not absorb excess water, it is necessary that insulation be provided. It should be noted that new sawdust contains special substances that prevent the cement from adhering to water. The consistency of the solution is not strong, therefore, this complexity can be prevented by wetting the sawdust before using them.

How to prepare a mixture on the basis of sawdust for thermal insulation of buildings

To create a heat insulator using sawdust and cement, the following materials should be prepared: for 10 buckets of sawdust take one bucket of cement and lime.All these components should be mixed for the perfect impregnation of sawdust with the prepared composition, carrying out the insulation of the roof or attic. Then it is necessary to dilute the antiseptic in water, pour this compound into the watering can to irrigate the mixture.

A check is made by taking a bit of the compound and squeezing it in your hand, if the water does not appear and the clump does not spill, it means that the solution is correct. In the next step, make-up of the composition with sawdust and cement with its layer-by-layer compacting is done. Full maturation of the blocks should be waited for at least two weeks.

Providing insulation of the ceiling, floor or walls with the help of the composition with chips, all work is carried out in a well-ventilated room. After two weeks, the places that were filled up, you need to inspect that will allow you to identify the presence of voids that occur during drying. In the presence of voids, they are filled with the composition with chips.

How to warm the attic, roof, floor, ceiling and walls with sawdust and will allow the insulation of the roof or attic. The solution is used to create plates, ideally stamped and dried. If chips are used in pure form without various impurities, then only to create plates. At the end of their need to carefully tamp and dry. The construction process does not use clean sawdust, because this material is highly flammable, it burns very quickly.

The construction process does not use clean sawdust, because this material is highly flammable, it burns very quickly.

Using chips, various heat-insulating materials are produced, such as pellet, ecowool, arbolit. They can produce high-quality insulation of attic, attic and other premises.

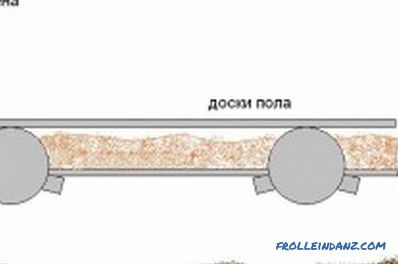

Preparation of sawdust for use.

It is possible to warm the floor using eco-wool with a special device for one-time use. Therefore, it is not recommended to warm the floor with ecowool with your own hands, as the device is expensive. It is better to entrust the solution of this task to professionals, and if you work manually, you can spend 40% more insulation.

To insulate the floor in the area where the air temperature does not fall below -20 ° C, it will be possible to use a thermal insulation layer 15 cm wide. At low temperatures, any 5 ° C frost requires adding a heat insulator with a layer of about 4 cm

By planning the insulation of the roof with sawdust, you can create blocks of chips. If you add cement and blue vitriol to moisten sawdust, they will replace the antiseptic. Then cement is added in the ratio of 1 to 10, which ensures uniform coating of chips.

In the presence of thermal insulation, the roof and other structures transmit heat, which is about 20%. Warming of the ceiling with sawdust should be carried out by performing the basic steps:

- Place asphalt on the ceiling surface.

- Process the boards with an ognebiozashchitny composition.

- Prepare a solution of cement and water (1 to 10) by adding 10 buckets with sawdust and 1.5 buckets of water.

- The mixture should be filled with a layer 2 cm thick over the entire overlap and compacted.

It is better to make insulation of the ceiling with sawdust in the summer time, since in this case everything will dry very quickly. The mixture after drying will not hesitate, but will only crunch under your feet. If you use sawdust as a heat insulator for walls with partitions, roofs, then the composition should contain lime and dry sawdust, taken in proportions of 1 to 10.

Did not find the answer in the article ? More information on the topic:

-

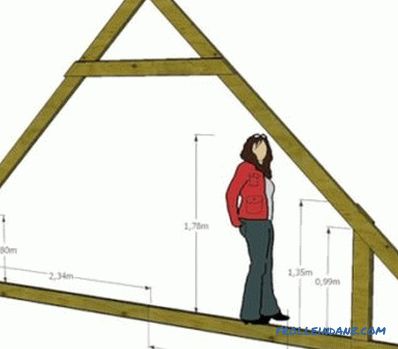

Types and features of truss

Roof truss structures: views, features of their installation. The elements that make up truss systems, their role in the overall design. The advantages of roof systems.