With modern buildings, it became popular to use the old interior, not the exception being log buildings. To build a bath or a house of logs is considered the key to prosperity and taste.

A wooden house retains heat well, has good sound insulation, but in order for the house to retain all these qualities, you need to properly cut down the frame.

The buildings are able to keep warm and maintain a pleasant woody smell. Being inside, you can feel the warm and dry air. This is due to the fact that wooden walls are able to provide natural ventilation. But in order to maintain the quality for many years, you need to know how to cut a log house with your own hands.

The walls of the log and bar are more durable, warm and have good sound insulation. Of course, it is much easier to build log houses from timber than from logs, since modern wood processing technology makes it possible to obtain timber of excellent quality.

Before building a log house, it is necessary to take into account that this pleasure is not cheap, but there are some advantages as well. For example, with regard to the tool, you will need only:

To chop a log house you will need an ax, a saw, a chisel.

- ax;

- saw;

- chisel;

- pencil;

- plane;

- roulette.

However, installation requires a construction feature that is not easy to buy, but you can do it yourself. To do this, you need a wooden bar, the edges of which are rounded by sandpaper. Two metal strips. Hacksaws are sharpened on one of the ends of the strips. Using scotch tape, the blunt ends of the strips are attached to a bar - a handle. The ends of the plates for the limb to the desired value are fixed with bolts with thread and nut. Twisting the nuts, there is an adjustment of the sizes.

Before you start felling, you need to decide which species is better to use, but for this you need to familiarize yourself with each one individually.

Cutting into a paw: some features of

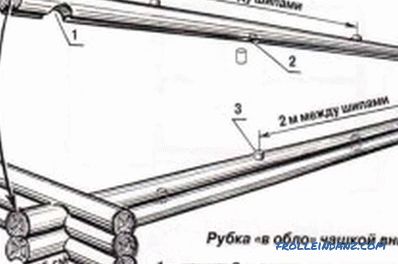

Cutting pattern in "flush".

This type of logging has its pros and cons. The advantages include the following characteristics:

- the least time-consuming process of cutting the connections;

- there is an opportunity for savings, since this type of installation is used to assemble the log in its entire length.

Minuses:

- because the corners are poorly protected, additional insulation will be required;

- the frame is considered unstable;

- its appearance is not very aesthetic.

The feature of log cabins is the correct form, since they have a “clean angle”, in order to give it an aesthetic look, the bars should be of the same thickness. It is also important to remember, the greater the thickness of the timber, the warmer the house will be. This is due to the fewest connecting elements.

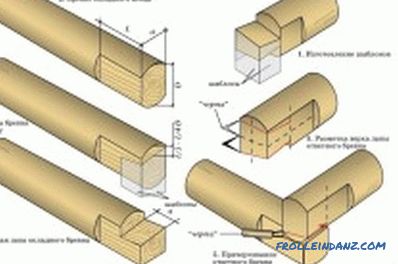

Marking a log for cutting into the paw

Using a grinding machine or a plane, one side of the bar is machined to a flat surface, which will serve as the inner side of the building. The opposite side should be processed only from the edge of about 2.5 parts of the diameter of the log. The remaining parties are also subject to processing.

Two logs are placed parallel to each other on a flat platform, and two more perpendicularly are placed on them. From the resulting square, the first crown is made by fitting. They should be customized using the level and after that make markup on both sides. It is important to remember that the size of the groove for planting logs should not exceed 1/2 thickness. The subsequent log is installed in the finished groove, and for a better fit, the upper part of the “paw” must be leveled.

If initially the “paw” was incorrectly executed, then it is already impossible to fix it, but you can level it by hammering a wooden wedge, but it is undesirable to do so.

At the initial stage, before you cut down a quality log house, you need to select the type of attachment of the logs.

This is necessary for a solid connection, otherwise the beam can be walked.

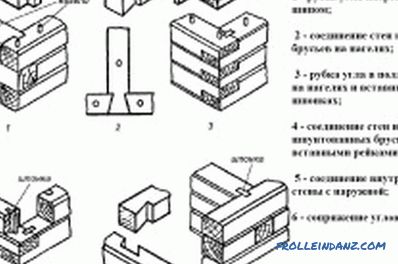

Schemes for cutting logs from a bar.

One option is to mount on the spike. In this case, a hole is made in the paw of the upper and lower lying logs and a straight spike is driven into it, of a slightly larger diameter. In order to avoid falling into the bottom spike, they are installed in a checkerboard pattern. For additional strengthening of the structure such spikes can be mounted in the entire length of the log, which will also help to avoid deformation during shrinkage.

Another option is better, but harder. For a beginner, he will not be able to. In this case, a spike should be left on the paw during preparation, which protrudes approximately 2 cm upwards. Thorn size should not exceed 1/4 of the working surface of the paw. On the log being laid on top, in its lower part, the corresponding groove should be cut, into which a thorn is inserted, where the legs lie on each other. Most often spikes are arranged in the inner corner of the log house.This method of laying bars is time consuming and requires jewelry work.

When laying the crowns, in order to avoid cold bridges, tow or other insulating material is packed into the gaps and gaps.

The final stage will be trimming the timber from the inside of the log house. But on this issue, opinions diverged. Some believe that such a finish allows you to make the interior more attractive and comfortable, a different opinion - the exotic natural material is lost, as well as the style.

After installation of the log house, the bars should be treated with antiseptic and antibacterial means of protection, this will help prevent material rotting and reproduction of tree insects and will increase the fire resistance.

A blockhouse “in the paw” requires additional warming of the corners inside or outside the wooden house.

Chopping of a log in a dovetail

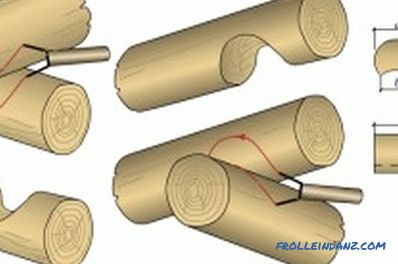

Compound of dovetail logs.

This method of cutting is similar to "in a paw". In addition, this option has all the advantages of felling "in the paw" and compensates for its shortcomings. In this case, the legs are not perpendicular, but have a slope angle. The angle has a radius that will allow to lay the next paw into the previous one. This kind of connection also has its disadvantages and merits.

The disadvantages include:

- the difficulty of making the paws at an angle with your own hands. The newcomer is not even worth trying without the help of a master;

- the tilt angle is able to pass moisture during rainy weather, this can be seen visually after drying the log house and when gaps are formed.

The process of laying does not differ from cutting into a paw, but there is one difference - at the completion of laying, there is a need to install waterproofing at the corners of the building to prevent moisture from entering. It is important not to forget that wet wood, after drying, is capable of deforming.

Cutting into a bowl: main characteristics

This type of log has its advantages:

Cutting "into a bowl"

- cutting into a bowl has a beautiful and aesthetic appearance;

- due to its connection this design is more durable and stable;

- such a frame has good thermal insulation;

- because of the aesthetic appearance, it does not require additional finishing.

Disadvantages:

- difficulty in mounting and felling;

- more material is needed, which means it will be more expensive than the cost of construction.

The connection is made by cutting or cutting the cups. Since the corners of the log have protruding ends of the logs, the area inside the building is reduced, but the stability increases, which allows you to build several floors.

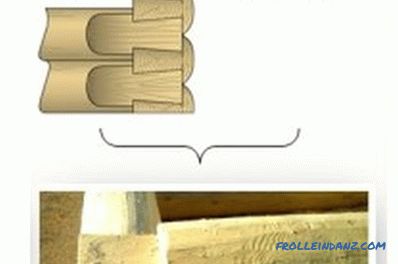

Preparation of logs before laying

The marking of the cups is carried out by a line that works like a compass. It is important to remember that the bowl should be located at the bottom of the log, as otherwise water can accumulate in it, which will lead to rapid deterioration of the wood.

When mounting a log, the logs should be stacked on top of each other so that the cup follows the contours of the lower log. The size of the bowl should not be more than half the cross section of the log.

Since such a method is more durable, there is no need to use an additional log connection using stake or spikes.

In order to properly cut a log house with your own hands, sometimes you cannot do without a master. This is due to the complexity of some nodes, and the accuracy of their implementation directly depends on the experience and skills of working with wooden elements.

Didn't find the answer in the article? More information on the topic:

-

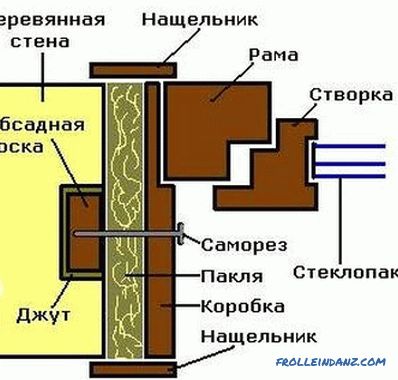

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.