Currently, timber is one of the most widely used materials in private house building. Many owners choose a felling for such qualities as practicality, durability, ease of operation, etc. However, in order for a house to last from a bar as long as possible, it must, among other things, be tiled. The lining of the log house can be started a few years after its construction, since the wood shrinks, and if the lining with bricks or any other material used for this is done ahead of time, it can be deformed and all efforts to enrich the structure will be in vain.

Facing the house with a bar can be made several years after the house itself has been built.

When is it best to veneer a log house?

Wood shrinks for 5-6 years. After the construction of the log house is completed, the wood should be sanded and treated with a special protective varnish. This procedure is carried out every 2 years for the time allowed for the shrinkage of the structure. If this is not done, the walls of the log house simply begin to rot. However, many experts recommend to perform facing of log houses at 2 years after the completion of its construction.

If the owner of the house did not polish the wood and did not open it with lacquer, it is impossible to tighten it with finishing the house for more than 2 years.

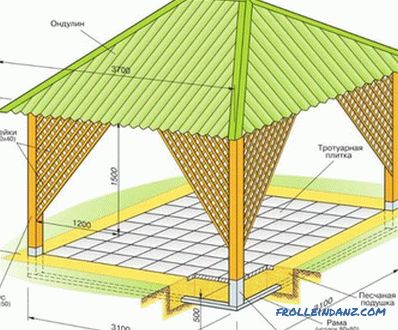

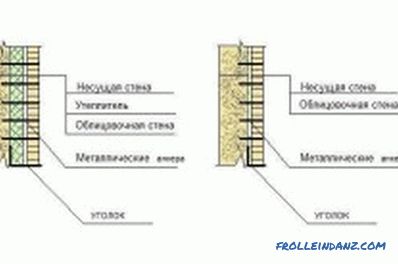

Scheme of facing a timber house.

In the modern construction market there is a huge range of materials that can be used for cladding a log house:

- Siding of various materials.

- Block house.

- Fiber cement panels.

- Thermopanels.

- Bricklaying.

- Wall paneling, etc.

In most cases, homeowners choose to veneer with vinyl siding and brick.

What material is best to choose?

To choose the most appropriate material for your case, you need to briefly familiarize yourself with the main characteristics of each of them.

So, vinyl siding is the most widely used material. There are many good reasons for this: the material does not lose its appearance and performance properties for several decades, it does not fade and does not need painting. And if a heater is secured between the siding and the walls of the house, this will save additional costs on heating bills.

Wall paneling helps protect your home from moisture and damp.

Wall paneling is the most environmentally friendly material among all listed. It will keep warm in the log house and protect it from moisture and damp. However, lining requires constant thorough care, for which most owners simply do not have the time or desire.

The block house is also a very good, but rather capricious material. It must be covered with special impregnations, which would ensure its reliable protection against various adverse external influences.

Metal siding is also very popular. It is characterized by high durability and fire resistance. Among the disadvantages of metal siding can be identified quite a lot of weight. It will exert a serious load on the foundation and walls of the house.

Fiber cement panels are represented in the widest selection of shades. They are made in a standard size, 300x90 cm. This material is well suited for facing the house. He firmly endures various adverse external influences, does not need additional care, retains its color during the entire time of operation. Installation does not require special skills and effort - the panels are simply fixed with screws.

Thanks to polyurethane foam insulation, thermal panels are able to protect a house in any cold.

Another popular and reliable material for cladding a log house is a thermopanel. In the composition of such panels there is polyurethane foam insulation. Thanks to this material, such cladding will provide excellent thermal insulation performance and will protect the house from the cold. The main disadvantage of this facing is its high cost.

Often, homeowners give their choice in favor of finishing brick with a log house. This material allows you to create unique design solutions. In addition, the brick provides the most comfortable conditions: in the summer it will keep the house cool, and in the winter - to protect from the cold.

Most often brick and vinyl siding are used for cladding a timber house.

The order of work will be considered on their example. Having dealt with the technology of working with them, you can without any problems perform the lining with the help of the other materials mentioned.

Step-by-step instruction on facing a house with siding

First of all, prepare the necessary tools.To independently revet the house with siding panels, you will need:

- Bar for assembling the battens.

- Thermal insulation material.

- Construction stapler.

- Level.

- Twine.

- Dowel-nails.

- Moisture proof membrane.

In addition to wooden, siding can be mounted on a metal frame. If you cannot find a suitable wood, use a metal profile. The skeleton is necessary, because the siding installation technology implies a ventilation device between the walls of the house and the panels. In addition, a layer of insulation must be laid.

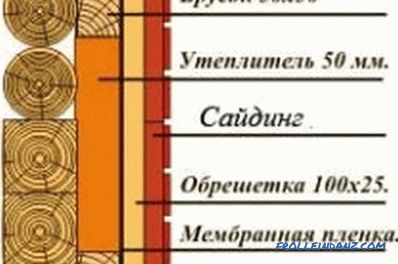

Scheme of the correct installation of siding.

Work begins with the attachment of the frame. Mount the vertical strips at a distance of 30 cm from each other. The cross section of the timber must match the thickness of the insulation. For fixing the batten, use the dowel-nails. Be sure to monitor the correct installation of the building level.

Lay the insulating material. The most commonly used fiberglass or basalt insulation. Attach a waterproof windproof membrane over it. Use for this construction stapler.

Next, you need to install the second row batten. Adhere to the same step of 30 cm. Thanks to this crate, a ventilation gap will be created between the waterproof windproof membrane and the siding. The gap must be at least 2 cm.

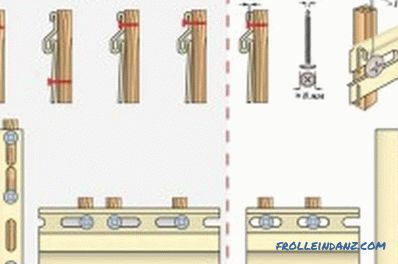

Take the construction level and twine. You will need to measure a distance of 77 mm from the lowest point of the wall of the house and draw a line around the perimeter. Above this line will be installed installation basement strip siding. It is fastened with screws or nails. On the panels for this created special holes.

The next step is to install the internal and external corner profiles. For fastening panels with each other special lock connections are provided. Gradually fill the entire wall from bottom to top. Siding panels are overlapped using a special H-profile.

A finishing profile is installed at the top of the wall. The edge of the last wall panel needs to be clamped and fixed in the finishing profile. If necessary, the panel can be cut to the width.

A guide to facing a log house with a brick

A plan for facing a house with brick.

Brick lining is performed using a whole set of tools, namely:

- Trowels and hammer-pick.

- Mashings and joints.

- Construction level and plumb.

- Wooden slats 2 m long.

- Cord-mooring and square.

- Reiki-order, folding meter and roulette.

A conventional mortar of 1 part of cement, 3 parts of sand, 5 parts of gravel and water is used to fill the foundation. For masonry suitable solution of 1 part cement, 3-4 parts of sand and water.

Before the start of the cladding, the house must be sheathed with insulating material. Simple sheet mineral wool will work well. More economical option - expanded clay. It is better to refuse use of roofing material. Wood is necessarily treated with antifungal agent. Processing is carried out 2 times. The second time it needs to be done a day after the first treatment.

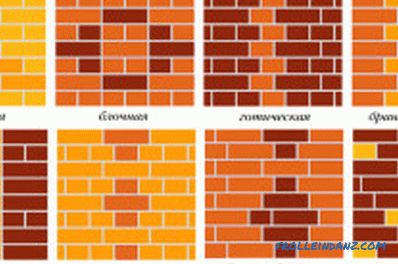

Types of laying bricks for facing a house.

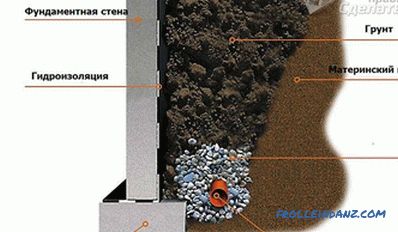

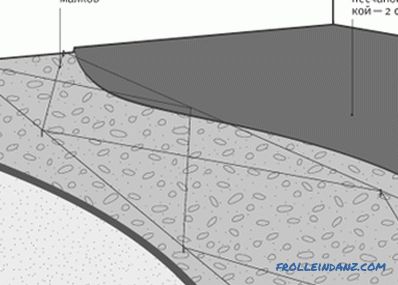

Brick cladding requires the construction of a full-fledged foundation about 30 cm wide. It will not be possible to manage with only a blind area in such a situation, it simply cannot bear the facing weight. Dig a foundation trench and fill it with mortar. Let the concrete harden and lay the roofing felt on it in 2 or 3 layers. The strip should protrude approximately 6 cm beyond the boundaries of the masonry on each side. Install the insulating material, preferably in 2 layers.

In the next step, you need to make a base. It is made of brick. Lay the first row of brick on the dry, taking into account the openings. Before you start facing you need to choose the type of brick and determine the required amount. At 1 m usually goes 50 pieces. Suitable silicate brick. If desired, you can use clay facing bricks.

Masonry is done in the usual way. In the solution you need to add so much water so that it does not flow, but it is also not too thick. Laying must necessarily be protected from adverse weather conditions. If it starts to rain during operation, cover it with plastic wrap. As a rule, cladding recedes from the wall of the house a maximum of 6 cm. Walls and masonry are tied with 10-centimeter nails. You can use chopped reinforcement, steel wire, etc. for this. Jumpers are usually used for openings.

Now you know how the cladding of a house built of timber is performed. By following these simple instructions, you can do everything yourself and save on the services of third-party craftsmen. You just need to spend a little time trying to figure out how to perform the lining, and you will succeed.Good luck!

Didn't find the answer in the article? More information on the topic:

-

Making a table in the bath with your own hands

It is easy to build a table in a bath with your own hands. Materials for the table use different, often take those that are on hand. Used wood has a number of requirements.

-

Installation options for sub-floor

Correct installation of the subfloor. Wet, dry and combined subfloor: styling features. Recommendations for the installation of the lower flooring. Necessary tool.