The circular saw, which is still called circular by old memory, is an indispensable tool for the owner of a private household. It copes equally well with wood and drywall, non-ferrous metal or acrylic glass, but one of the conditions for quality and trouble-free operation is regular sharpening of the cutting disk. The purity and durability of this tool is much higher than other types of tools for cutting hard materials.

The circular saw (circular saw) is designed for cutting a wide variety of materials. In the process, the teeth are blunt and need proper sharpening.

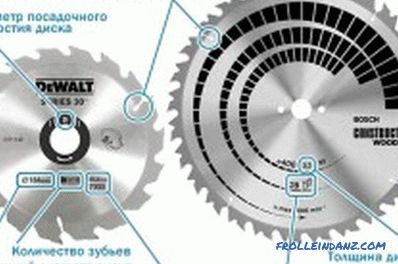

The circular in no way inferior to a popular chain saw chainsaw, and even in many ways superior to its capabilities. With its help it is possible to produce transverse, longitudinal or inclined cutting of the material necessary for the construction or manufacture of joinery products. The number of teeth on the disk of the circular saw depends on the hardness of the material being processed, but in any case, only correct wiring and sharpening of the teeth can ensure its unobstructed movement.

Signs of wear of the circular saw

Circular saws, in compliance with all rules of operation and meticulous care, have reliability and durability, but, like any tool, require preventive maintenance from time to time. If the operation of this equipment became noticeable and there were dark marks on the surface of the material, it means that the edges of the saw blaze from excessively heated saw teeth. In combination with smoke and an unpleasant odor at work, which can occur from overheating of the engine casing, this most likely indicates that the tool requires immediate sharpening.

Timely sharpening of circular saws to a large extent affects the smooth operation of the electric motor.

Circuit disk for circulars.

A blunt disk repeatedly increases the load on the mechanism and may lead to its complete failure. The main degree of wear falls on the upper cutting edge of the teeth on the circular saw blade. In order to avoid blunting of the tool, it is necessary to regularly check the radius of rounding of the cutting edge, which according to the rules should not exceed 0.1-0.2 mm. It is possible to determine that an urgent sharpening of the circular saw is necessary according to the shape of the kerf itself. Regular sharpening of the disk will not only prolong the equipment's uninterrupted operation, but also increase productivity, as well as reduce the time and effort that is spent on putting in order a completely worn-out tool.

Sharpening a circular saw with your own hands

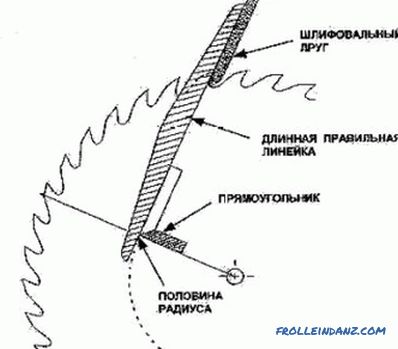

The method of sharpening a circular disk depends on the availability of the necessary tools. If it is not possible to use a special machine for this purpose, then a good result can be achieved with a minimum set of files, a vice and a pair of wooden blocks for fixing the disc.

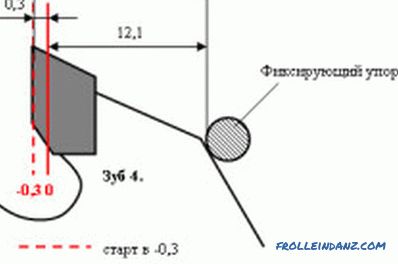

Scheme of sharpening a circular disk on the machine.

It will be more convenient to sharpen a part if you do not remove it from the machine, but first you need to remember to disconnect the equipment from the power supply. To begin with, it is necessary to ensure reliable fixation of the disk, using wooden blocks, planted under it on both sides. The gear disk, which is separate from the saw, is placed in a vice, holding it with wooden wedges. It is better to mark the first prong with which the treatment will start, using a bright marker, so as not to perform actions on the second circle.

Begin work from the back surface. When grinding teeth, it is necessary to control the uniformity of the applied efforts as much as possible and to try to observe the same number of file movements in each case. In order to train your hand in this action, you can use an old hacksaw for a start, which you will not mind spoiling.

Checking the quality of the grinding wheel is carried out during trial cutting. Uneven material progression and background noise may indicate that the teeth are at different levels. This can be identified by bringing the marker close to the cutting edge of the disk and making its full turn in the opposite direction to normal work. Teeth that have received markings require file re-processing.

Didn't find the answer in the article? More information on the topic:

-

How to sharpen a circular saw

To understand how to sharpen a circular saw correctly, you need to know what kind of tooth wear falls on the upper cutting edge. You also need to know the geometry of the tooth and the basic rules of sharpening.