Some rooms are not designed for laying floorboard due to their purpose. For example, it is a bathroom, a kitchen, a place by the fireplace or a bath in the bath. How can we make so that the two materials are combined and looked in a winning light. Docking of the floorboard and tile with special materials will help. The combination made on conscience is difficult for distinguishing from the whole cloth - such it makes impression.

A joint between parquet and tile.

What are the difficulties of combining? It would seem that the two materials ideally lying on the floor of the joint simply do not require. However, such is only tile, and parquet is a material that changes with temperature, humidity, load and other things, that is, whimsical. There will be no problems with it if it is laid in a limited area without transitions to other surfaces.

The grooves and locking connections are securely coupled to each other and the movement does not move. The situation is different, if you want to make a flat floor in rooms, overlapped doors. For example, in the kitchen, dining room or living room.

The main materials used

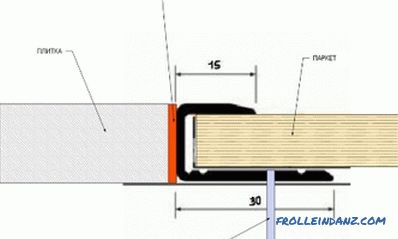

Stages of joining the floorboard and tile.

- Sealant. It must, of course, be in harmony with one of their coverages. But this method of joining has some drawbacks - it is very difficult to choose the initial background and the durability of the sealant is not up to par. It quickly comes to a sloppy look, falls off in pieces and has an unpleasant smell of vinegar during installation.

- Cork. These are pieces of material cut from the whole web. This joint looks beautiful in combination with the wood flooring and tile. But there is a nuance - the joints need to be done before scraping and grinding the surface, and this is work for the masters. However, an invaluable advantage of such material is the possibility of joining various geometric curves, since it is amenable to any action, and even floor cushioning, which will not allow the board or tile to be damaged during operation.

- Liquid plug. Material based on glue with cork added to it. Convenient because it allows you to firmly hold two materials together after solidification. Even unprofessional will cope with drawing. Installation is carried out before the scraping.

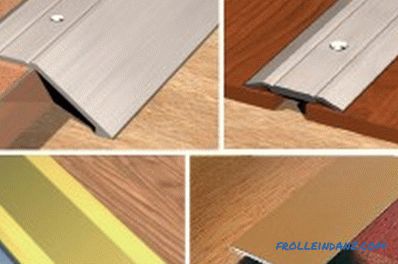

- PFH and metal profiles. The easiest to install, but decorative leaves much to be desired. Although if made without any complaints, they can be a border of two materials - boards and tiles. The minus is quite significant - such materials can only be used in a straight line, they are not subject to bending.

Installation with conventional sealant

What you need:

- composition;

- syringe gun;

- gloves;

- spatula;

- lubricating oil.

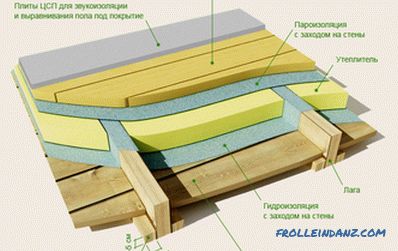

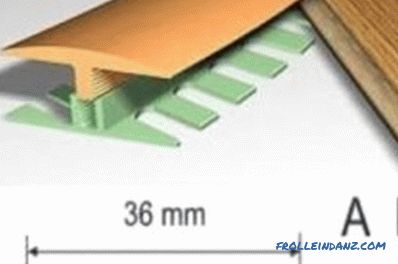

The cork compensator, when joining parquet and tile, makes it possible to make the floor surface perfectly smooth without sharp drops.

The joint surface is oiled. Can be used to machine sewing machines or automatic trimmers. It is convenient to apply a few drops from the bottle. With a clean cotton pad, you need to rub the drops on both surfaces. This is done so that the sealant, in the case of careless use, can be easily separated from the tile or board.

Then the bottle is inserted into the pistol, and in even movements without movements, the composition is found in the gap where the joint should be.

If you get too much protruding edges, then with the help of a spatula, surplus level with the floor is immediately removed. In this way, the compounds will be flawless.

It is best if an extruded and smoothed sealant layer is pressed into the seam. This will help its durability - hitting such a strip would be a problem.

Complete drying of the compound will occur after 24 hours. During this time, you need to try not to walk on this section of the floor, so as not to cause a displacement of the joint.

The method is not the most time consuming, but it requires accuracy.

Errors when working with silicone sealant:

- Make a thick layer of strip. When removing surplus, you can completely pull it back.

- Work on short lengths. The reason is the same.

Features of working with a cork

What you need:

- sheet or cork mat;

- scissors;

- clerical knife;

- measuring instruments.

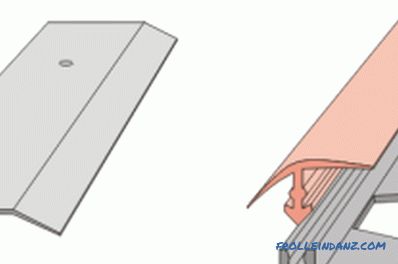

Options for patch slats for joining floor coverings.

Stripes are cut from the sheet to seal the seam. They are made in such a way as to be 2 mm wider than the gap. Because nothing will be used to fasten such material - the cork must fit tightly.

Next, the material is placed in the seams. There are no problems with such work. It is only important to ensure that it is flush with the edges of the board and tile. To do this, use the stationery knife - they cut off excess cork.

At the end of the work with the compactor, the paper should be scraped and ground. Then the connection and the appearance of both surfaces will be perfect.

Since installation involves the use of special machines for subsequent work, of course, skill in work is necessary. Better to trust the pros.

Errors when working with a stopper:

- Cut the material into segments. Need all the length of the joint.

- Make the material thinner than a seam or flush (a little more) so that the cork fits tightly. By neglecting this, it is possible to achieve that during scraping the material will fly out.

And if a liquid tube is used

Additionally you will need:

- a tube with the composition;

- a stationery knife;

- butter.

As with the sealant, two surfaces are wiped with oil using a tampon or cotton pad.

Then, gradually squeezing out the mass from the tube, fill the gaps between the tile and the board with a liquid tube. If the floor in both planes is perfectly level and represents a single canvas, then problems should not arise. Otherwise, it is necessary to focus on the edges of the surface that are higher. And on them to equal the cork.

Options for joining various coatings using powder.

After hardening, the excess is cut with a knife, while trying not to damage either the board or the tile. It will happen no earlier than a day. But the flaws from the surfaces must be removed immediately, so that the adhesive composition is not tightly pressed. Make it easy if the floors are covered with oil.

Then work on scraping and grinding. As is clear from the written, the work is simple, but the home wizard can not cope with the chiseling. However, if you dare, it will turn out and this.

Errors when working with the liquid plug:

- Do not use oil to protect the edges of different materials. In the end, she firmly stuck to the floor, and it is difficult to otkovyryat such glue. If the tile still somehow turns out, then the parquet can be spoiled.

- Do not level the composition above the surface. This is fraught with gaps and leaks fit.

- Do not allow the composition to completely harden. Day minimum.

PVC profiles and metal

List of requirements:

- a profile suitable for one of the coatings;

- a screwdriver;

- drill with pobedit drill;

- awl;

- self-tapping screws or decorative nails;

- tape measure and pencil.

First, the required piece of material is cut.

Installation of a flexible nut for joining floor coverings.

It is worth considering that its length is the entire length of the joint plus 1 cm. With a pencil you need to outline the border where the profile of the joints will be laid. Simply put, circle it around the contour so that the middle is just at the seam.

Then, you first need to drill holes in the tile. Make it will be very difficult, because it has a tendency to crack. Therefore, a good quality drill is used, with a diameter not less than self-tapping screws. The points where the drill will be directed, should be slightly knocked with an awl, slightly tearing off the top layer of ceramics. So it will be easier for the drill to enter and the risk of tile cracking will decrease.

If the profile already has ready holes, then it is simply applied and secured with screws through two fasteners. This is for a flat lining. Then spin and the rest. However, if the profile is clean, it must be prepared in advance - drill the holes in accordance with the places where the tile contains them.

It is convenient to hide profiles with elevation differences of different surfaces. Usually the parquet is lower than the tile, if it was laid by a non-professional, therefore the overlay is made in this correspondence. It is necessary to ensure that the fit of the profile goes completely. And if this does not happen because of the large difference in the height of the surfaces, then such a material for combining the joints should be abandoned.

This is how the floorboard and tile dock with PVC or metal profiles.

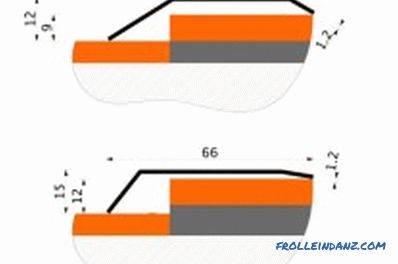

Sizes of multi-level powders made of stainless steel.

Errors when working with profiles:

- Attempting to bend it under geometric shapes. The result of decoration will be zero. If the floor has convolutions, then the use of the profile is best avoided.

- It is impossible to use a material with a threshold if its installation will be centered or diagonal to the floor. Such models are used only for doorways. Otherwise, every time you can hear the curses of the home, if they will cling to the thresholds of the toes.

- Attach a profile from different ends. Plastic models are very resilient, and “waves” can be achieved with this kind of work.

- Twist the screws to below the profile level. This way they will be less noticeable.

- It is impossible to make installation of the joint of the parquet board and tile with a profile, if the difference in height differences is significant - from 0.5 cm.

Care of joints of surfaces from different materials

All of the above options for sealing joints are too afraid of moisture. Except, perhaps, traffic jams. The sealant falls off, the profile can go rust.What to do, because wet cleaning is an integral part of keeping the house clean? The answer is one - do not overdo it. You can wipe, you can not wet. And be sure to dry!

Floors are the face of the house. Even if they are just clean, the impression of comfort is created immediately. And if the surface is a beautiful connection, then just no words. Their decoration should be done in detail. At first it is worth considering whether there is enough skill and patience for such work, and then proceed. One thing can be considered for sure - any independent process will bear fruit if there is a desire to make your home unusual and beautiful.

Didn't find the answer in the article? More information on the topic:

-

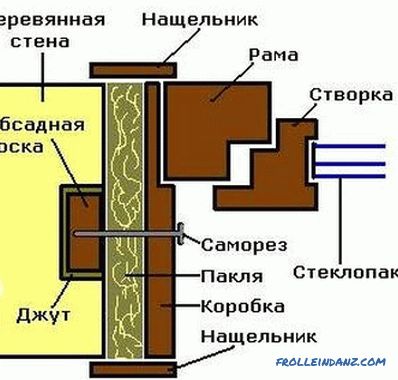

Wooden windows: DIY-making

Do-it-yourself wooden windows: the advantages of installing wooden structures. Varieties of windows from natural breeds. The stages of the manufacture of wooden windows, installation design.