In European countries, it is customary to divide linoleum into only two types: household and commercial. Well, in Russia they decided to single out another kind. This is semi-commercial linoleum, whose characteristics are only slightly inferior to commercial. That this material and what properties it possesses will be discussed in this article.

How the material is arranged and where

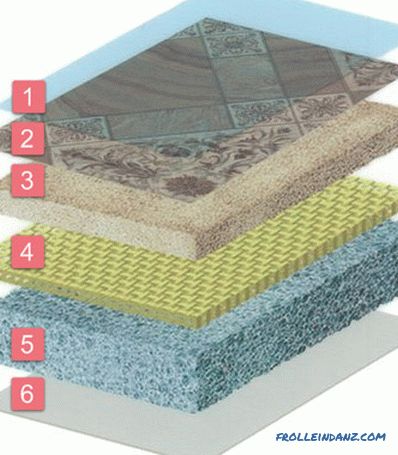

semi-commercial type linoleum is always composed of several layers (that is, it is heterogeneous).

The structure of the material is close to the structure of household linoleum:

# 1. The topmost layer is protective. It does not allow the floor to wear off prematurely, spoiling the drawing. This layer is thicker than that of household linoleum.

# 2. The finishing layer gives the product completeness and forms its appearance. Linoleum can be one-color (and the palette is very extensive), and also have a print under a tree, stone, metal.

# 3. Basis for drawing.

# 4. Fiberglass. This increases the reliability of the web and saves it from deformation.

# 5. Polyvinyl chloride base

# 6. The back layer with markings.

Semi-commercial linoleum is also called office, since it is mainly taken for office floors. However, it can be used both in polyclinics, and in kindergartens, and in stores. For home, this durable material also works well.

Since there is no provision for GOSTs for this material, it is somewhat difficult to classify a particular material as the so-called semi-commercial linoleum class. However, manufacturers of this material themselves maintain certain standards by which it can be determined that it is semi-commercial linoleum.

Usually this type of linoleum has the following parameters:

- The thickness of the product is from 2.2 to 4.5 mm;

- thickness of the upper layer (protective) - from 0.35 to 0.6 mm;

- weight of one square meter - from 2 to 5 kg;

- abrasion - from 10 to 15 g / m2;

- Standard width - from 1.5 to 5 m (with an interval of 0.5 m).

How semi-commercial linoleum is classified according to wear resistance

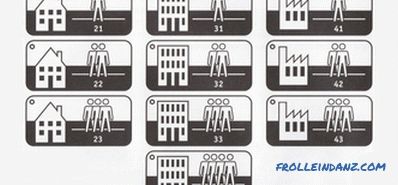

In order to select semi-commercial linoleum that is most suitable for specific conditions, you need to understand what the numerical designations mean in its labeling. This is not difficult. In our country, adhere to European standards for the classification of floor coverings and premises where they are used.

According to these rules, there are 3 types of premises:

- Residential type of premises is indicated by 2;

- office type is indicated by 3;

- the production type is indicated by the number 4.

In addition, another parameter is classified - the load to which the floor covering is exposed:

- low loads in the marking indicate the number 1;

- with an average load - the number 2;

- with the increased load - the number 3;

- with a very large load - the number 4.

To make it more visual, manufacturers are also nachki-icon placed next to the numbers. They depict houses and men. Looking at the figure and the number next to it, you can quickly figure out whether this linoleum will do.

Take, for example, the material marked with the number 32, it is suitable for office space, and class 31 is good for a house where a large family lives.

Abrasion group

Sometimes types of semi-commercial linoleum can differ significantly in cost. As a rule, more expensive material has less abrasion. This indicator is designed to determine how quickly the floor will wear. The abradability group must be calculated according to the European standard EN660-1.

The abrasion group is determined as follows: a sample of the tested linoleum is applied to a rotating disk with an abrasive applied to it. When this disk will pass 25000 turns, make measurements. By comparing the initial thickness of linoleum with that obtained after testing, you can determine how the coating has worn off. In accordance with this, he is assigned one of the abrasion groups.

This parameter depends on both the thickness of the protective layer and its composition. Pure PVC is the least susceptible to wear, with no impurities. This composition is usually covered with high quality semi-commercial linoleum. If chalk and quartz sand are added to PVC, the strength of the coating decreases.

The following abrasion groups are distinguished:

- Group T - material with PVC protection. When testing is erased by 0.08 mm or less.

- Group P - the average degree of wear. Erasing the top layer - from 0.08 to 0.15 mm.

- Group M - weak resistance to abrasion. When checking lost from 0.15 to 0.3 mm of the protective layer.

- Group F - material with an unacceptably large amount of impurities - more than 65 percent. Its strength is very low. Erasure - from 0.3 to 0.6 mm.

Semi-commercial linoleum has abrasion - from 10 to 15 g / m2 and group P.

About the thickness and quality of the protective layer

one of the most important characteristics of semi-commercial linoleum. Thanks to a protective transparent film, the pattern does not lose its freshness, and the coating itself wears out more slowly. After all, only this top film is erased during loads.

If the thickness of the upper protective layer is from 0.3 to 0.6 mm, then this means we have semi-commercial linoleum or, as it is also called, household reinforced linoleum. Naturally, with an increase in the protective layer, the price of the product also increases, but its service life increases significantly.

Some manufacturers add additional useful properties to the protective layer. So, for example, the company Tarkett, using its own technological developments, makes the coating comfortable for cleaning and especially durable:

- Thus, the EXTREME PROTECTION protection increases the strength of Tarkett linoleum seven times (compared to conventional type).

- The TITAN layer is an additional lacquer coating.

- TUREX is a special embossing method that makes Tarkett linoleum as similar as possible to one of the most expensive natural materials: stone, wood or ceramic tile.

Embossed linoleum.

Basis of semi-commercial linoleum

The basis of a semi-commercial coating can be:

Felt (needle material)

Polyvinyl chloride (foam type)

The use of PVC backing is a relatively new technology, had time to gain popularity. After all, the joints of such linoleum are very easy to combine with a special compound for cold welding of PVC materials. Moreover, the connection occurs at the level of molecules, so it turns out hermetic and completely imperceptible (in contrast to the standard way of joining - sills). Places of joints will not be afraid of moisture got - it will not pass inside.

But even the felt igloprobivnoy basis has its advantages. For example, it is perfectly glued to any surface, and also very durable to break. And on the linoleum with such a base less noticeable dents from something heavy, and the affordability of the price is more attractive.

The length and width of semi-commercial linoleum

Here semi-commercial linoleum boasts a variety. Manufacturers produce its width from one and a half to five meters (in steps of half a meter). This is not bad - you can always pick up the material that will give the minimum amount of waste. And the seams at the joints can also be done less. Well, the length of the rolls are not so different - usually they are from 20 to 30 meters.

Total Coating Thickness

This parameter affects properties such as noise insulation and heat insulation. And it is pleasant and comfortable to walk on thick linoleum - it springs thanks to cushioning. Usually semi-commercial coatings are made with a thickness of 2.2 to 4.5 mm.

How much does linoleum weigh?

Weight determines such characteristics of semi-commercial linoleum as density and strength. After all, it depends on the density whether the floor will withstand the heaviness of the legs of a loaded cabinet, the walking of shoes on sharp heels or the ride of a chair on wheels. Weight is determined per square meter - it usually lies in the range from 2 to 5 kg.

About fire safety

In accordance with fire regulations, all materials used in everyday life, at work and in offices, have a certain degree of flammability. For linoleum defined 4 degrees - from G1 to G4. Most of these coatings are attributed to the degrees G3 and G4 (combustible materials).

There is also a flammability index (B), for which 3 groups are assigned, as well as the ability of smoke formation that has 3 groups (D). The RP abbreviation denotes the degree of flame spread - it relates the material to one of four groups. There are a number of other indicators. The main thing is to remember the rule: the larger the number following the letters, the more combustible the material is.

In semi-commercial linoleum the situation is as follows:

- Flammability degree G3 - G4;

- flammability of group B2 - B3;

- ability to smoke - D3;

- ability to spread flame - FP1 or FP2.

What else should be considered - additional parameters of semi-commercial linoleum

On the roll with the material there is a certain number of icons, pictograms. It would be nice to understand them - it will help to avoid mistakes when buying:

- If you see an icon depicting a lightning, then that is good. It means that linoleum is antistatic and will not accumulate electricity, suddenly shocking it.

- Wheel icon, look for if you are going to move furniture on wheels on the floor - bedside tables, chairs, tables. Such linoleum will surely endure all this.

- If you are going to arrange underfloor heating, then buy linoleum with the "warm floor" icon.

- Finally, one more parameter - residual deformation. Semi-commercial coating has it at the following level: ≤ 0.17 - ≤ 1.33 mm.

Table: Properties and characteristics of semi-commercial linoleum

| Parameters | Values |

|---|---|

| Wear resistance class | 31, 32, 33 classes. |

| Group and degree of abrasion | From 10 to 15 g / m 2 , group "P". |

| Protective layer thickness | From 0.3 to 0.6 mm. |

| Basis of semi-commercial linoleum | Felt (needle-punched material); Polyvinyl chloride (foam type). |

| Length | From 20 to 30 meters. |

| Width | 1.5; 2; 2.5; 3; 3.5; four; 4.5; 5 m. |

| Coating thickness | From 2.2 to 4.5 mm. |

| Linoleum weight | From 2 to 5 kg / m 2. |

| Flammability | Degrees G3 - G4. |

| Flammability | Groups B2 - B3 |

| Ability to smoke | D3 |

| Ability to spread the flame | RP1 - RP2 |

| Residual deformation | ≤ 0.17 - ≤ 1.33 mm. |