A folding table is an indispensable furniture in small apartments. Such a table with your own hands can be made of chipboard, MDF and wood.

A folding table is an indispensable type of furniture for small apartments.

From tools, you will need sandpaper, drill, 5 and 8 mm drills, jigsaw, brush, screwdriver, hammer drill, hammer.

Preparatory work

Experts recommend first finding a reliable system that can keep the table open. To install the table with your own hands, you need to buy corners with a shoulder at 350x550 mm. These parts are cut out of plywood or chipboard. They are fastened to the hinges with screws. Otherwise, you can buy special factory mechanisms.

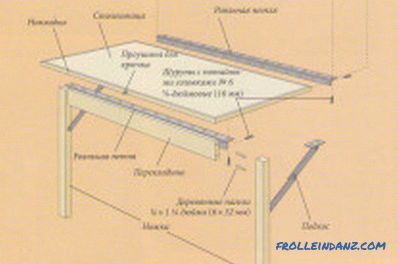

Drawing of the folding table.

Pre-prepare the drawing of the product. If desired, a folding table can be made with shelves and legs. The main thing is that the furniture frame should have the same width and be securely fixed to the wall. Anchor bolts are used for this. The main elements of the furniture will need to be made of laminated chipboard with a thickness of 18 mm. The component parts of the product include (mm):

- worktop - 650x1100;

- bottom and top of the shelf - 150x1100;

- partitions and side panels - 150x500;

- 2 niches - 150x400;

- a small partition - 150x241;

- the back part is 11x95x535.

From the accessories, you will need butterfly loops, anchors, confirmats 5x70, self-tapping screws 4x16.

Self-assembly

Folding table assembly scheme.

Parts are recommended to be cut to order. Similarly, you can do with pasting edge. The next step involves assembling the shelf. Details with confirmats. In the plane will need to make through holes. To do this, use a drill bit of 8 mm. Holes are made in the end with a 5 mm drill (60 depth). Then the installation of the hardboard and the installation of the piano loop are made (with a uniform indentation from each edge).

The last element needs to be mounted on the bottom of the shelf, which is attracted to the sides and partitions with the help of confirmatics. The distance from the bottom of the niche to the level of the floor should vary between 700-730 mm.

In order to assemble the mechanism with your own hands, you will need to mark up the forged corners along the holes in the corresponding hinges.

For this purpose, metal drills of 7 mm are used. The hinges are fixed with screws and nuts, the length of which is 350 mm. If necessary, drill holes in the loops for a similar diameter. Buy should only mirror mechanisms.

Then indent from the bottom edge of the hinged shelf (down 10 mm). Mechanisms attached to the wall. Plywood is screwed to the bottom of the table top (parallel to the wall surface). At the same time, a distance of 350 mm from the side, which will be fixed to the shelf, is observed. Piano loop opens. The table top is laid on the corners. If the design is smooth, then 4x16 screws are screwed into the 2 outer holes of the hinge. Folding furniture ready for use. Finishing works are carried out taking into account personal preferences and financial capabilities. If you wish, you can use the services of a professional designer.

Didn't find the answer in the article? More information on the topic:

-

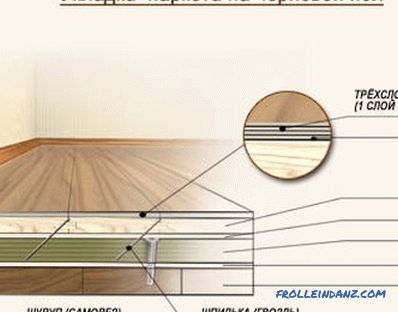

How to lay a wooden floor in a private house

In order for a wooden floor in a private house to serve for many years, certain laying rules must be followed. Better yet, make it multi-layered. This will improve the heat and sound insulation.