Construction of a log house involves the use of various technologies. A log house can be erected from a chopped log (manually cut) or from a log, rounded on a special machine.

Various technologies are used to build a wooden house with their own hands. Modern construction methods allow machining the frame to the desired shape, cutting a groove in the logs for subsequent fixation into the crowns. Each size is calibrated to an accuracy of 1 mm. The construction of a house (according to this method) is presented in the form of a designer's assembly. In carrying out such work will need to make a drawing.

If the house is built from a rounded log, then the bark and upper layers, including sapwood, are removed first. The next stage involves the treatment of wood with special impregnations. The diameter of each element must be more than 300 mm. The project, on the basis of which the log house is being built, can be bought off the shelf or be carried out independently.

Object walls can adjoin each other at a different angle. This is due to the fact that in logs you can cut out a bowl of the desired shape. Builders distinguish 2 methods of building a house:

The 1st method is characterized by the use of a forest of natural humidity. When choosing a material take into account its density. Logs should have a yellow or dark yellow surface. The cut should be smooth and dense, without resin pockets. The crack in the wood can have a depth of not more than 1/3 of the cut.

For self-construction of a log house you will need to buy beams, rafters, logs, roofing material, tape measure, level, buckets, boards, self-tapping screws, and screwdriver. Then prepare the plot for the future structure. Wood should be stored under a canopy. Since the building being erected has a small weight, it will be necessary to make a shallow foundation for it. To this end, experts advise to pour the pile foundation, slab, pile or recessed tape construction.

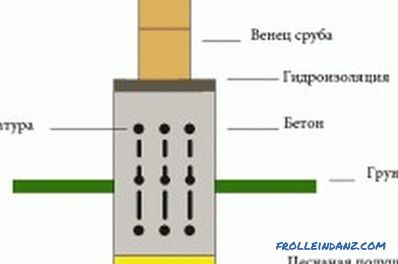

Scheme of the foundation for a log house.

For the arrangement of the pile-strip foundation, it will be necessary to mark the site. Then the top layer of the earth is removed. The width of the structure is dredged with a depth of 30 cm. Around the perimeter of the building are equipped with wells whose diameter is 180 mm and a depth of 150 cm. A layer of rubble and sand is poured into each well. From the reinforcement prepare the frame, which is lowered into the well. The next stage involves pouring the pit with concrete. Apply a vibrator to tamping.

Planks are used for arranging the formwork. The structure is mounted above the ground level in such a way that it protrudes 50-60 cm. For a strip base, it will be necessary to weld a frame that is associated with the reinforcement sticking out of the wells. The next step involves pouring the base. If the foundation has hardened, then it is waterproofed. To do this, it will be necessary to lay a roofing material (3-4 layers) on the surface, additionally smearing the material with mastic.

Rules for erecting walls

The mortgage (1st) crown cannot be mounted on the base of a log house. Pre-laid on the foundation board (linden). For this you can use a timber, whose thickness varies from 50-100 mm, and the width - no more than 150 mm. The next stage involves the assembly of a log house.

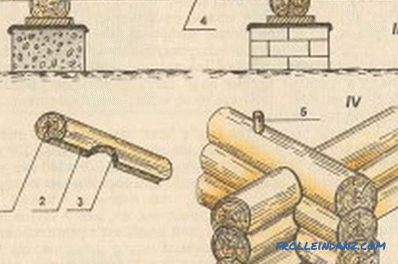

Scheme for building walls from logs: I - cutting down the cup down; II - chopping up; III - the correct laying of the log with a cup; IV - the angle of the log; 1 - treated log; 2 - groove; 3 - a cup; 4 - residue; 5 - nog (thorn).

Initially, logs (1-2 pieces) are placed on opposite walls of the base (parallel to each other). Each log house has a factory longitudinal and locking corner joint. The next stage involves laying wood on the other 2 sides. Top put insulation. The groove and dredging of the bowl are filled with moss, tow, jute and other material for the caulker. The heater is laid in such a way that it hangs down from all sides by 5-6 cm. A construction stapler is used to fix it. Since jute tape completely covers the groove, and in the bowl runs in the middle, in the last element the material is set in 2 segments. The notch is filled with insulation.

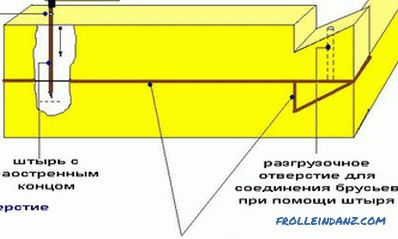

In each case, 2 logs are mounted on the transverse sides of the foundation. They rely on a mortgage crown. Between the wood you need to respect the angle of 90 degrees. Builders advise to regularly monitor their horizontal position. The remaining crowns set in a similar way. Some modern technologies of building a log house include the use of dowels (for fixing crowns).

The considered elements are presented in the form of wooden slats made of solid wood. In each log, you need to make a hole into which the nog is inserted. The remaining 2 crowns are not fixed (for shrinkage).In the factory logs provided holes for the door and window openings.

Installation of the roof

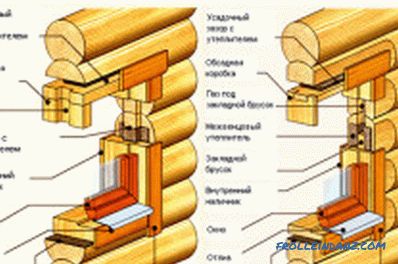

Installation of windows in a log house.

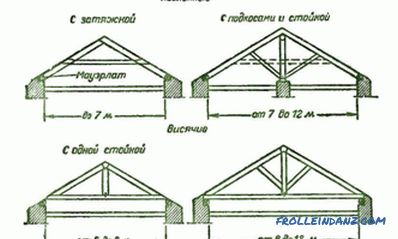

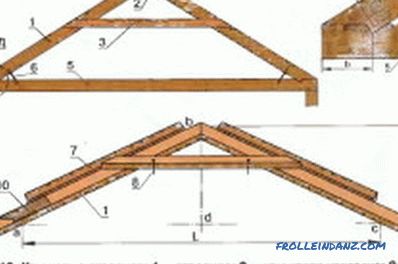

The next step involves installing the roof. Beams and rafters included. The last elements are mounted on the logs of the upper crown. If desired, pre-stack mauerlat. If a veranda is provided in the project, then shrinkage compensators are inserted into the supporting frame (vertical arrangement). To prevent the structure from being skewed, each vertical log is equipped with the latest elements.

Metal studs are used to connect ridge analogues. Rafters mounted in 600 mm increments. This will require a bar with a cross section of 50x200 mm. To fix the structure to the last crown used sliding support. Top lay waterproofing material. When mounting the batten, a step is observed, which depends on the type of roofing material used. The next step is to install the roof.

Upon completion of the installation of the roof will need to caulk insulation. This will require a special tool. The material is wrapped 5-6 cm down, pushing in the gap between the rims. In this state, the house is left for a year (for its shrinkage). After a specified time, the caulk process is repeated. Formed slots are jute or hemp.

Installation of the roof of a log house.

Some builders recommend holding the caulking of a building after its annual operation. An important point in the construction of a log house is the installation of doors and windows. Partitions and openings are mounted one year after the construction of the building. Pre-set casing with special fasteners. Windows and doors are inserted into the resulting structure. Since wood tends to expand and shrink, the process in question takes a long period of time.

Construction of the floor of a log house provides for a tie-in of a lag in the mortgage or a subsequent crown. The last elements must be securely fastened. The crown is in need of good ventilation. Experts recommend to mount the flooring on the upper crown lags. At this stage, the installation of various communications, including heating systems, baseboards, plumbing.

If the construction of the house is made from logs of insufficient length, then docking is allowed.