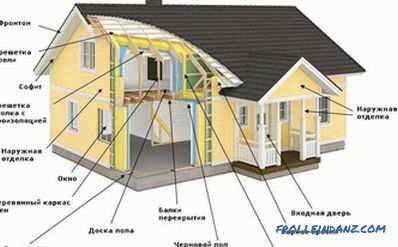

When building wooden houses, fixing issues occur quite regularly. There may be fastening directly to the boards to each other or to any already existing structures (fastening the beam to the wall or foundation). This occurs during the construction of timber and frame walls, internal partitions and truss structures.

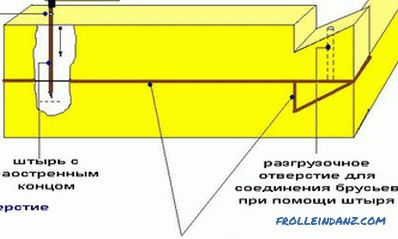

Scheme of fastening a beam using a metal pointed pin.

Types and nuances of fastening of a bar

Connections of elements during the erection of any structures are called cuts. Depending on the interposition of the parts to be joined, there are several types of nipple joints:

- Extension - an increase in length in the vertical direction. The load from the top of the joined parts is transmitted to the underlying part along the axis of the connection.

- Splicing - increasing the length in the horizontal direction. The load in this case can act in various directions: along the axis of the joint (compression or tension), lateral loads (in the horizontal or vertical plane).

- Splicing is a joint that increases the overall width of the part being produced.

- Knitting-fastening parts to each other at different angles in both horizontal and vertical planes.

Tools and working methods

The method of fastening a beam using the soft method with staples.

How to fix the timber? Fastening is mainly carried out due to the formation of a “thorn-groove” or “lock” system on the parts being joined. The elements of the fastening connection are made using:

- saws (electric or manual);

- ax;

- hammer;

- wide chisel or chisel ;

- drills;

- marking tools.

The formation of a spike on all types of joints is carried out by sawing a bar across the grain of the tree along the marking line and then removing excess material with an ax or chisel. A groove is formed by sampling wood with a chisel or chisel. To increase the stiffness of the connection (if the design permits), the fastening of the bars can be additionally reinforced with wooden (dowel) or metal fasteners (brackets, bolts, self-tapping screws).

Bar building: features

The simplest type of building is butt jointing. With this type of connection, the mating parts are connected to each other closely by detached ends. To resist random lateral loads, one or more dowel rods (or metal pins) or fastening brackets are installed at the ends, overlapping the parts connecting line (i.e. a peg is installed).

The sturdy butt joints are single or double spikes. The spike and groove in this case are formed with the help of tools directly at the ends of the connected products.

Splicing of a bar: nuances of

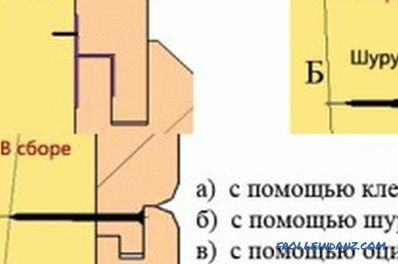

Schemes of rigid attachment of the bar.

Splicing end-to-end is the same as building up end-to-end, with the only difference that the parts are connected with additional brackets.

A kind of end-to-end joint is a joint called a butt flange. The peculiarity of the connection in this case is the formation along the entire surface of the end face on one beam of the ridge, on the other groove.

There are also splices with a straight or oblique overlay. The joint is a sample of half the thickness of the timber with each of the fastened parts. After which the products are connected and secured with fasteners. Splicing with an overlay is designed to increase the length of the structure; the main requirement for the operation of such a connection is an even, firm base on which the part spliced in this way will lie.

Bars spliced into the overlay do not withstand the tensile stress. Most often, splicing with an overlay is used to increase the length of an element when building walls of a house or when establishing a support beam on a foundation during the construction of frame structures.

In order for the joint to withstand the tensile load, splicing with a straight or oblique lock is used.

Structurally, such a connection is similar to a splice with a pad with a small spike (lock) added at the end of the splice site.

Unification: practical recommendations

“in a paw” and “in a half-tree” connection scheme.

When ralanging several products, you can get an element that is larger in size, which will work to resist the loads as a whole. This method of fastening is often used in the absence of the possibility of manufacturing support beams from solid material.

Distinguish:

Composite beam with keys. The element is attached to the element end-to-end, along the entire length of the mate grooves are made, where the inserts (keys) of hard wood are installed.The direction of the key fibers should be perpendicular to the fibers in the product itself. The width of the key should be 4 times the depth of the key socket. At a certain interval, the products are bolted together.

Composite bead with gaskets - the design is similar to the keyway. The difference is that instead of dowels used gaskets.

The arrangement of fibers of the gasket elements in this case will coincide with the fibers in the parts to be joined. Bolts are installed at the ends of the gasket products. The design allows you to attach the timber to the timber to obtain beams of increased thickness.

A special case of rallying is the wall of a log house. Here, on the entire upper surface of the product, a ridge having a quadrangular profile is formed. A reciprocal groove is formed along the bottom surface.

Tying a beam: some moments

The design of tied bars is very diverse and depends on the operating conditions of the connection.

The following types of knitting are distinguished:

- In a half-tree - on the joined bars it is cut in half a section.

- In a paw - it is used for the cabin of corners at construction of a felling.

- The slotted spike is a connection that is well opposed to uncoupling fastened parts to the sides. To prevent destruction in the longitudinal direction, it is additionally reinforced with bolts or pins, depending on the magnitude of the load. There are single and double thorn.

- A spike hem is a special case of butt splicing or splicing.

- Tooth trim - used for attaching rafters and truss elements. A groove is formed on the beam, into which a fixed timber can be fitted.

- The cutter is used for fixing the bars at a right angle. Works well in stretching. Visually, such a connection resembles the “dovetail” connection.

By the way, very often to facilitate and speed up the production process, the bars are fixed using special mounting brackets. However, In any case, do everything right, because a violation of attachment of the bars in an important joint can lead to the destruction of the whole structure.

Didn't find the answer in the article?

-

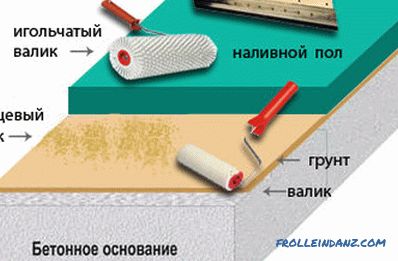

Floor alignment nuances

Floor leveling is quite possible . Zhno perform their own What tools are needed for this methods: cement and dry screed, self-leveling floor Which option is best