Different materials are used for self-construction of the sauna room. Their choice is most often caused by their own desire, which does not go against the available material means. The most popular building materials for construction are brick and concrete.

Drawing of a bath from a log house.

Recently, the majority has resorted to the use of cinder blocks. But the priority for the construction of this Russian bath has always been wooden bars or logs. They have long been famous for producing beneficial for the body substances that are mixed with steam. Making a log cabin with your own hands is a task that almost everyone can do. After all, it is much easier to build a bath room from wood boards than from any other building materials.

Self-construction of a wood sauna

Materials, tools and accessories that will be needed to build a bath:

Laying of bars .

- logs of various tree species;

- protective mixtures for processing bars (antiseptics);

- boards, concrete mortar, crushed stone and reinforcement for the foundation;

- wooden pins or iron pins to connect the bars;

- hydro and thermal insulation materials;

- bitumen, roofing felt and slate;

- extended set of woodworking tools.

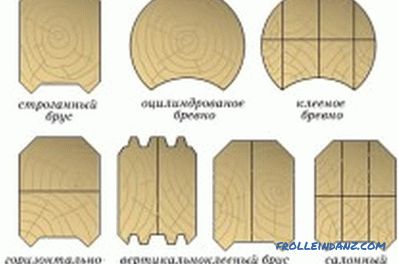

First you need to decide which building material will be taken as the basis of the building. Simple and round logs will require more experience in the construction of the bath. Even the most experienced builder will be able to make a competent log house from a wooden bar. In this case, it is enough to follow the instructions described below. In this case, do not even need the help of a qualified specialist.

Selection and sorting of wood

Before construction work, first of all, select high-quality wood, because the durability of the room depends on it, let alone its simplicity of maintenance. But the choice of a good building material does not guarantee good quality, because it needs to be competently processed and prepared for operation.

If you decide to make a log house from logs, it is advisable to mine them in the winter. It is not recommended to use young wood. In addition, after cutting a tree, it is best to let it dry for 30-40 days. Logs should lie down exactly in the form in which they were cut. It is necessary to start processing after the expiration of the period for drying logs.

Scheme of the first crown.

Independent production of bars will require careful processing of logs. First of all, you need to make a complete cleaning of the bark. In order to avoid cracks that may form at the moment of bark removal, it is necessary to leave strips at both ends of a log 15 cm wide.

Wood storage has some nuances that need to be considered:

- logs should be placed at a height of 20 cm from the ground;

- wood should be folded in bundles or piles;

- the interval between logs should be at least 5 cm.

Important The process is the selection of logs for the manufacture of the log house.

During the sorting, you should leave only high-quality wood, simultaneously discarding fragile and unreliable logs.

Inspect the building material being prepared for damage and cracks. If the bathhouse is built from such logs, it can collapse at the construction stage, let alone wear during the period of further operation.

Pay attention to small patches of dark blue. Their presence indicates the beginning of the process of decay from the inside, which is caused by fungal invasion. You should not risk and use such logs, it is best to postpone them for heating the sauna stove.

The same should be done with wood, which is eaten from inside by insects. It will be necessary to make sure that the affected and high-quality logs are far from each other, otherwise the infection may spill over and damage suitable construction materials.

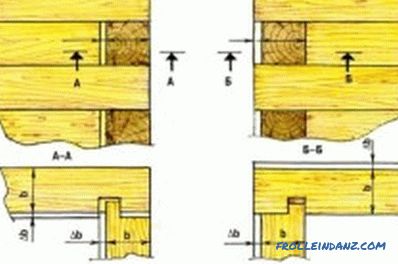

End connection of bars.

A bathhouse that is used to build a room should have a smooth and uniform surface. This will relieve you of problems when laying logs in the process of construction of the structure. You should not immediately mix them with firewood, since such logs are still useful for making small parts for door and window openings, as well as for the floor and ceiling.

In the process of building a bath-house, the type of trees that is used as building material is also important. The lower level is best laid mainly from larch, and subsequent levels can be stacked from cedar, pine and spruce logs.This is due to the increased resistance of larch to natural effects, it is more durable and tends to harden with the passage of time.

The bath walls are more protected from ground moisture, but they require enhanced thermal insulation properties, so coniferous trees are the best choice for their construction. In addition, they release substances that are beneficial to the human body, saturating well with steam.

Base of construction

The main convenience of building a room under the bath is laying the boards directly on the foundation. This greatly simplifies and shortens the construction period.

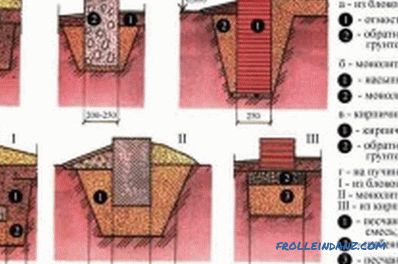

There are 2 methods of laying the foundation for a log cabin: tape and columnar.

Scheme of strip foundation varieties.

The belt method implies the arrangement of formwork along the edges of the entire area of the proposed building, which is subsequently poured with concrete. The foundation level must be at least 0.5 m from the ground. This will help protect the lower level of the log house from moisture and decay in the future.

The internal area of the base is filled with rubble or sand in the form of small tapes. The laying of the lower level of the bars can be carried out only after the concrete solution has completely hardened, that is, after 15-20 days.

The bar method is more common. In this case, supporting pillars on a brick base are erected at the corners and edges of the square. The same pillars must be built indoors, namely in places where bearing walls will be located. The interval between the pillars must be at least 150 cm. In certain situations, it can be extended to 200 cm, but no more. All support posts must be reinforced with concrete at the base.

Regardless of the foundation method, it will need to be strengthened with reinforcement, which improves the reliability and stability of the lower level of the log house.

The main element for ensuring the durability of a building is waterproofing. For this reason, it is necessary to lay the waterproofing material in 2 layers. It is located between the base of the structure and the lower level of the log house. First of all, the foundation should be covered with liquid bitumen, on which roofing material is laid. Once the structure has hardened, this procedure must be performed again.

Laying of the lower level of the log house

Splicing of timber along the length.

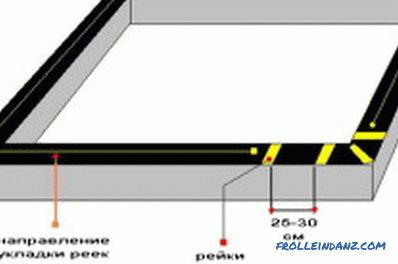

Laying of the first level of the bars is performed along the entire perimeter of the foundation. First of all, you need to equip the base rails, which were pretreated with protective mixtures. Their thickness should be no more than 1.5 cm, they are placed with an interval of 25-30 cm.

Reiki provide reliable protection against moisture and rotting of the lower level of the log house, increasing the durability of the structure. The empty cavity between the slats is filled with heat insulating material.

The main factor in laying the lower level of a log house is almost perfect uniformity of building materials, so you should choose the most even bars. Otherwise, the further erection of the structure can cause many undesirable problems that will require extra time and effort to fix them. Uniformity should be measured by the level of construction, evaluation of the suitability of bars by eye is unacceptable.

For the lower level, you need to make bars, taking into account that they will be used as support, that is, you will need to select the thickest and strongest during processing. The standard size of the log house for the lower level is 20 cm in diameter. The remaining bars must have a diameter of not less than 15 cm. The length is chosen on the basis of the estimated area of the room, and all the bars must have the same size.

The log house should not be laid too tightly, as in the future, the bars settle down and are compacted naturally. There is no need to fix the main level at all. With the passage of time, it will condense under the high pressure of the upper level bars. It also makes it possible to update the lower level without forcibly dismantling the outer walls.

Scheme of species and cross sections of the beam.

At the corner points of the joints of the bars, special cuttings must be made to ensure the reliability of the structure. This process will require accurate measurements that are considered at the log processing stage. Properly making cuts, you need to connect the bars into a single structure and fill the remaining cavity with insulating material between the foundation and the lower level.

The main level of the log house must be treated with protective mixtures from all sides, especially in places that are adjacent to the foundation. In addition to protective mixtures, it is recommended to apply slightly thickened technical oil to the bars.

After laying the lower level, you can proceed to the arrangement of the upper rows.

How to make cuts correctly?

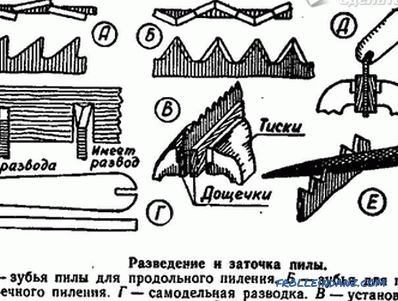

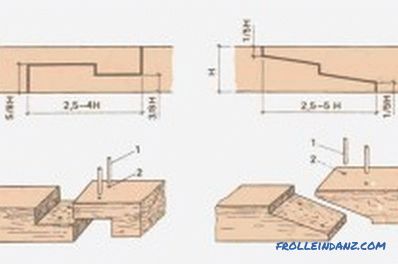

There are a number of methods for strengthening the bars at the ends, but the most popular and simple way is to cut the cuts.

Beam orientation schemes.

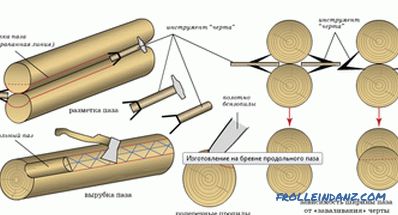

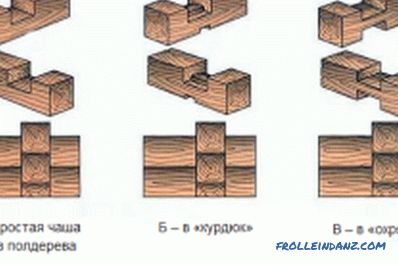

Logs with surplus in length imply cutting cuts in these places. Cuttings are of 2 types: one-sided and double-sided. The first type is made according to the principle of cutting a regular bowl into a half-tree, and the second one is caused by cutting out notches of different sizes at both ends, that is, into a rump or into the ocher.

In the absence of a surplus, the corner cuts are made in the main part of the bars. In this case, you can choose the type of reinforcement without the presence of insert elements (in the paw or in the spike). If the connection still implies their presence, then you need to use the half-tree method on the insert spike. The simplest method of cutting is the method in the paw, which will require less builder time and effort to equip the cuttings.

Having selected the most suitable method of corner mounting, you need to perform an accurate measurement of all the logs, on the basis of which the template for the cut will be created. After that, you can begin processing the bars. First of all, you need to make transverse cuts to half the diameter of the bars. Following this, you can cut longitudinal bevels. It should be borne in mind that the processing of larch logs is much more difficult, since this breed has a high density.

Construction of the upper levels of the log house

Connection diagram of the end connections from the bar.

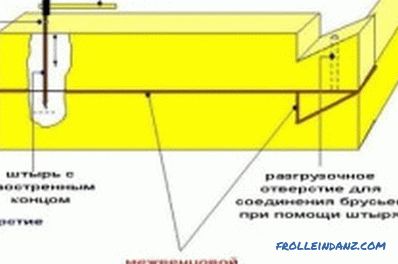

The walls of the sauna room are built in a certain sequence. Bars are placed, trimmed with the help of construction level and strengthened at the ends. In the role of fasteners are special pins made of wood or iron pins that must be hammered into the openings reserved for them. The size of the openings should coincide with the diameter of the fasteners.

The interval between the openings should be 1-1.5 m. The bars should be drilled through and up to half of the downstream log. Then you need to postpone the upper timber and drive into the opening of the lower pin, the length of which is equal to the height level of 2 logs. Before placing the upper beam will need to lay insulation.

This method is used to lay all the other rows, while the 2 upper rows do not need to be strengthened. In the future, the upper bars will need to be removed to arrange the ceiling.

During the design of a bath, it is necessary to take into account the locations of windows and doors. During the construction of buildings in the marked places leave gaps of small size, which are subsequently cut out, forming openings of the required size.

At the completion of the construction of the bath-house, it is necessary to prepare the building for a subsidence period that lasts about 6 months. To do this, lay on the upper rows of the log boards 4-5 cm thick, which are covered with slate.