The connection of the rafters is necessary when building elements, joining with a power plate, in a skate, with additional elements of the system (racks, tightening). Methods of fastening wooden structures are selected depending on the scheme trussing system, the preferences of the master, the characteristics of lumber. It is usually used planed timber or spliced across the width of the board.

Scheme of rafters.

There are slanting, hanging rafters that transfer the load from the power frame of the roof to the walls unequally.

Additional elements are:

- ridge runs;

- racks;

- struts;

- crossbars;

- fillies.

They give the spatial structure the necessary rigidity, increase the operational resource, safety of use. For any type of connection, fasteners are used.

Building rafters

With large dimensions of a building, the standard length of lumber is not enough, so the timber has to be increased. The connection of rafters along the length is made by several technologies:

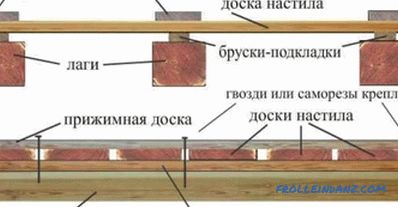

The splicing scheme of rafter legs.

- overlap - no trimming of the ends of the parts is required, the overlap is not less than 0.7-1.2 m, the chess arrangement of the hardware;

- butt - the elements are fixed by toothed plates or wooden overlays, self-tapping screws are offset;

- on the girder - the assembly is strengthened by resting on the longitudinal beam or board;

- oblique prirub - corner sawn timber, fixing in the through hole with studs / bolts (10-14 mm ) with wide washers;

- "three boards" - double overlap, excessive increase in weight of the truss system, maximum rigidity, strength design.

The last way to connect the rafters is used in the manufacture of complex roofs mansard, hip type. Empty gaps after the joint node are filled with sawn timber. using the same thickness of the board.

Connecting the rafters with bearing on the girder allows you to increase the pace of work - all the blanks of one slope are the same size, sawn off according to a pattern. When using half-timbered construction technology, metal parts for fixing are traditionally replaced by cutting all the elements into each other. This provides maximum rigidity. The method of oblique overlapping is more often used for hanging rafters, butt joint - for napsal variants.

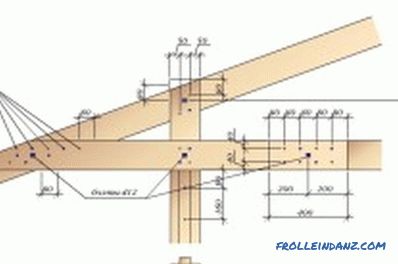

The upper ridge knot

The rafters in the skate mate rely on each other or on the ridge girder. In the first variant, the template method is used:

- triangular structures are prepared in advance;

- extreme triangles are mounted;

- the cord is stretched along them horizontally;

- average constructions are established.

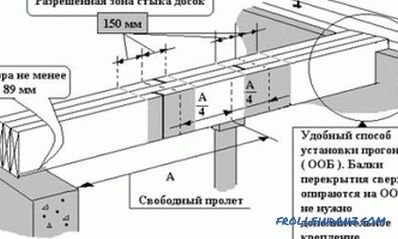

The scheme of splicing rafters in the skate area.

The connection of the rafters in the skate with the girder does not require horizontal control with a cord, the guide is the girder itself. Pre-assembling of truss trusses is not required, the roof is assembled from the sawn-top lumber in place.

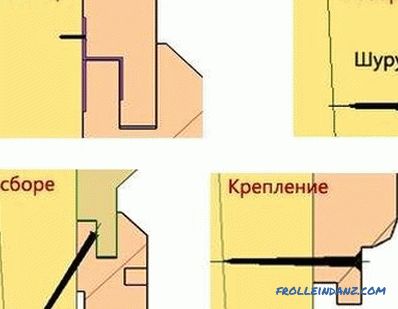

The connection of the ridge knot is performed using one of three technologies:

- overlapped - the ends of the rafters are cut off after fixing nails, self-tapping screws, transverse plates to each other;

- thorn groove - the connection is similar to the previous one, however, each edge has a half-tree selection;

- trimming the ends - the rafter is strictly vertical, the cutting angle is marked in place, the elements abut each other.

All connections should have the same degree of freedom, the minimum. This is due to the shrinkage of lumber in the first 1.5-2 years. Otherwise, the design will weaken, collapse under its own weight. Therefore, fastening with bolts or studs in through holes is always preferable to nails, screws.

Rafters can also be fixed with special hinged metal elements that are worn on the timber or attached to it with self-tapping screws. This slightly increases the cost of construction, but dramatically increases the resource, maintainability of the roof. Connection with two degrees of freedom is used in complex structures.

Lower support node

In the lower part (conjugation of the roof slopes with the walls of the building) the rafters rest on a longitudinal beam called a power plate. It is fixed in the upper perimeter of the walls in such ways as:

- wire strapping;

- putting on the studs;

- sanding into concrete, brickwork.

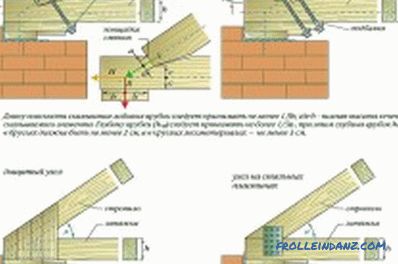

Options for cutting rafters into the beam.

Depending on the layout of the rafters, the loads either push the walls of the building or squeeze them.The hard connection between the rafters and the mauerlat has two types:

- retaining beam - rafters are cut at an angle, lean on the mauerlat inside or outside the building’s perimeter;

- The saddle is limited to a third lumber height to maintain load bearing capacity.

In order to connect the cut-out on the mauerlate, three hardware are used: one passes through the entire thickness of the leg at a 90-degree angle, the other two are mounted on the sides. When leaning on the mauerlat in the first way, lateral shift is excluded by fastening on both sides of the bearing angles. There is the option of supporting the puff when the cross beams that extend beyond the perimeter of the walls fall on the mauerlat. The triangular truss truss rests on these beams, the timber is fixed similarly to a heel with three screws or nails.

The main purpose of the puffs is to compensate for wall-pushing loads.

They perceive the efforts from their rafter legs, change their direction to vertical, which is favorable for the resource of the building box.

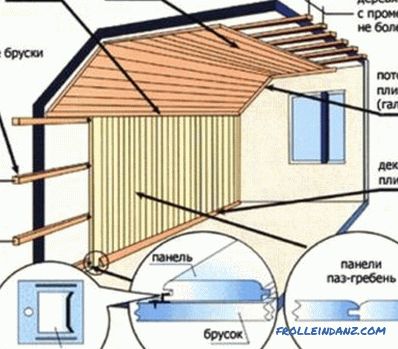

Sliding metal fasteners are often used for wooden cottages that are prone to shrinkage. It adds the required degree of freedom to the lumber in the longitudinal direction. This technology provides maximum maintainability of the roof, all loads are compensated by the system itself.

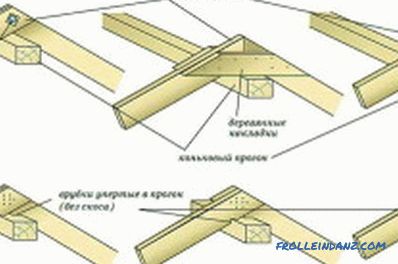

Crosscutting scheme of rafters.

Additional elements have their own methods of fastening:

- a board crossbar is overlapped on the legs;

- the squared crossbar cuts into the saddles of both legs;

- racks are usually cut into the legs, connected to beams-couplers with corners;

- ridge girders are built up by the methods indicated above because of their long length;

Pattern manufacturing techniques for roof trusses are always preferable to on-site assembly. In this case, the slopes are guaranteed to have a rectangular rather than a trapezoidal shape, which facilitates the laying of the roofing material, ensures maximum aesthetics of perception.

When using a cutter of the bottom of the rafter legs into the mauerlat, the saddle can be cut in any element of the structure, depending on the required size of the overhang of the eaves. In practice, the mauerlat is cut less frequently than the timber from which the rafters are made.

In hip roofs, each truss leg consists of two parts that join at an angle to each other. Ways of fixing timber, boards in this case do not differ from the above. The most commonly used method is the three boards with the filling of the internal space with scraps of lumber of the same thickness.

The choice of sliding fasteners is justified only in the case of a log, frame technology for the manufacture of walls. Panel, half-timbered structures do not shrink vertically, so the rafters to the mauerlat, the tightening beams can be fixed rigidly.

Didn't find the answer in the article? More information on the topic:

-

How to properly fasten eurolining?

Step-by-step instructions on how to fix the lining with your own hands. Materials and tools needed for work. Installation of this coating using klyaymerov.

-

Guide to covering the balcony with a tree

The process of covering wood balcony. The necessary tools and material for plating. Warming and creating a frame for plating. Features trim the walls of the balcony or loggia.