Looking at the showcase with a neatly laid out tool, just the eyes run, impact drills, drills, screwdrivers. All of them are a bit similar in appearance, and it seems to many that this is one and the same thing. Let's find out in all details how the drill differs from the punch and in what case this or that tool can be useful to you. To begin, consider for what and in what cases you can use a particular tool.

Where and why use a drill

To begin with, let's talk about drills. Even a well-versed person knows that with this tool, if necessary, you can drill large or small holes in almost any material. If the drill is equipped with a percussion mechanism, then it can also punch concrete walls (that is, work in percussion mode). However, this mode is easy to turn off by switching to the traditional drilling of holes, which is very convenient. But on this area of use of the drill does not end.

Depending on what material you need to drill, different types of drills are used, which both look different and are designed for different purposes.

1. So, for drilling a wooden surface, drills for wood will be useful, but in most cases they are replaced with conventional drills for metal. In some cases, drill bits are used for drilling wood.

2. If you have to work with metal, then the drills need others - more durable, having a specific design.

3. And with tiles and glass it is necessary to be more careful - look at that, instead of a smooth hole, it will work. Therefore, to solve such problems, there is another type of drill - it is a spear-shaped drill for ceramics and glass.

4. For making holes of large diameter, the best option is a crown-type drill.

5. As mentioned above, when the hammer drill works as a hammer drill, it can hammer concrete and brick. Although it does not become a full-fledged perforator, it can perform works of moderate complexity. For these purposes, drills with pobeditovye tips.

To grind the surface with a drill, it’s enough to use a grinding wheel as a bit.

If there is a need to perform cleaning of various metal surfaces on the drill, it is enough to put on a special brush of steel wire.

If the wire in bunches of the brush is twisted, then the treatment will be rough. For finer finishes, use a grooved wire nozzle.

If you need to mix some weight, then the drill is easy to turn into a mixer. For this, too, there is a special nozzle.

Because of this, the impact drill is a versatile device that can perform many functions. In the presence of some additional tools, she can work with a mixer, and with a screwdriver, and a grinding machine, or, if the slotting mode is on, with a perforator.

Why use a punch

This tool is used to break any materials. It is often used as a steep "pro", engaged in the construction and repair on a regular basis is not the first year, and home craftsmen.

Using a perforator, you can:

- drill a hole in concrete, brick,

- blocks, remove the plaster;

- knock down tile;

- to break off bricks;

- to make concrete walls shaton.

Without this tool, you can’t repair or build a house. It is convenient to work with him - he is fast and has almost no return.

Tool attachments can be:

- drills;

- chisels;

- core drills;

- peaks.

As for a snap, it may have a tail of two systems. This is either SDS Max or SDS Plus.

The SDS Plus system is distinguished by the presence of four oval grooves for mounting. Two of them are in the butt and are open, the other two are hidden. When the shank is inserted into the cartridge, it moves along the open grooves, as along the guides. Special locking balls fix it in closed holes.

Drills with SDS Plus Shanks.

In the SDS Max system, there are not four, but five recesses for fastening. Now there are three open grooves, so the drill is holding more firmly. Such a system is most often used in professional tools.

The chisel nozzle is put on the punch when something has to be dismantled. Nozzle-peak is used for shtrobleniya walls before laying wires or to make holes in the wall. Nozzle-crown will help to make a large through hole.

Differences of the drill from the punch

The main difference is the system of the percussion mechanism

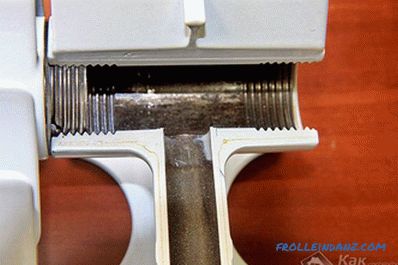

The most significant difference between the perforator and the percussion drill is the principle of the percussion system.So, at a drill for formation of blow two gear gears - a ratchet serve. The tool holder is rigidly connected with the first one, and its body - with the second one. When the impact mechanism is not needed, a stopper is inserted between the ratchets, and they have no contact. When the impact mode is activated, the stopper is removed, and the gear train converts the rotational movement of the cartridge into a forward-return movement.

This process is just beautifully shown in the next video clip, despite the fact that the speaker in the video constantly calls the impact drill a punch, in fact, the clip shows the work of a conventional impact drill. Just where the translators and the announcer know the difference between the drill and the blow function from the punch, they did not read our article :).

Video: The principle of operation of the hammer drill

The punch is different. The impactor can be either electromechanical or electropneumatic. The most commonly used is the first type. In this case, there are two coils that, with electromagnetic interaction, cause the core to move back and forth. Further, the energy is transmitted directly to the working part of the perforator.

The pneumatic mechanism can be of two kinds. Equipped with a crank drive transmission or a system with a so-called “drunk” rolling bearing. In the latter case, the rotating rotor drives the piston, which transmits the impact energy of the working part.

Video: Impact mechanism of the type “drunk” bearing

Well, and the crank mechanism of the crank type transmits its rotational energy with the help of a piston, which gives compressed air a push perforator.

Video: Shock crank mechanism

Well, and the crank mechanism of the crank type transmits its rotational energy with the help of a piston, which pushes the working part of the punch with compressed air.

Video: Percussion crank mechanism

Functionality - this is important

In this regard, the perforator is significantly ahead of the drill - because it has three modes work. This is rotation, punch with rotation and just punch. Accordingly, using an electric perforator, you can not only drill a wall, but also pierce it. To gouge a big hole, to pierce a groove for a cable, to chop off a piece of a wall - all this can be done by such a powerful tool as a perforator. But the drill with a hammer mechanism has only two modes - standard drilling and drilling using a hammer. Moreover, the force of this blow is not as powerful as that of a perforator.

How do the main characteristics differ?

For electric drills, the main characteristic is the torque, or torque, moment. The unit for measuring it is the Newton meter. Perforators are classified according to another feature. For them, the main thing is power, which depends on the impact energy. This value is measured in joules. A torque punch does not have to be large, it is often much smaller than the impact drill with a similar engine power.

Leader in performance

And then the puncher again takes the lead. After all, the impact energy of him, no doubt, more than the impact drill. Therefore, it is much more comfortable to work with a perforator - it is not necessary to press it so hard as on a percussion drill. Working with the latter, without significant pressure, it will be extremely difficult to punch a hole.

Main application

For a drill, the main area of application is the work of drilling metal, tile and wooden surfaces. Well, a perforator is designed to overcome the concrete and brick walls. Therefore, both in terms of hours or minutes spent and in quality, it is difficult to compare the result of work done by one and another tool. Indeed, for a drill, the impact function is only an additional one. However, as well as functions of drilling at the puncher. Do not neglect the instruction, using the tool "to the fullest" where only a short-term mode is allowed. Sadly it will end - a good thing will break.

Summing up

Now, imagining the difference between a hammer drill and a perforator, the choice will be made easier. Choose a similar tool, when you have all the details to present, for which you may need it. If you have to work with brick and concrete, then in the store look to the side, where perforators lie on the shelves. If such work as punching the walls, is coming very rarely, do not spend money on a powerful punch. It is quite possible then to do with a hammer drill. It will only be needed if you intend to perform such work often and for a long time.

Video: Impact drill or punch