In the process of laying a floor covering a mandatory step is the installation of a sand-cement screed. With its help, the surface is leveled, on which this or that floor covering will be laid later. It acts as a strong foundation. The amount of components used in the process of mixing the solution, how it was mixed, depends on the strength of the entire screed.

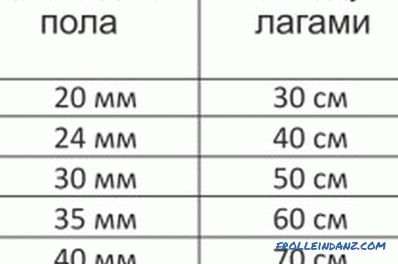

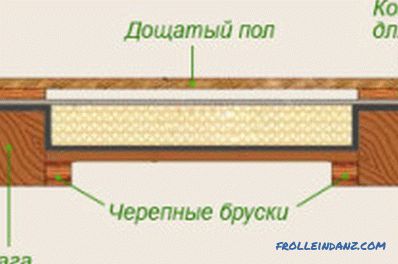

Scheme of arrangement of wooden floor in lags.

In addition, the type of overlap that the screed was made of affects strength. The most difficult option is to screed the floor on wooden lags.

How to prepare the foundation correctly?

Before you start arranging the screed, you need to calculate all its parameters. This list includes: how much cement is contained, the thickness of the whole layer, whether it is necessary to install a reinforcing mesh. If, nevertheless, it is not possible to do without reinforcement, then it is necessary to determine its type, diameter and size of the cells. If it is assumed that there will be increased pressure on the floor in the future, then reinforcement should be carried out in two layers.

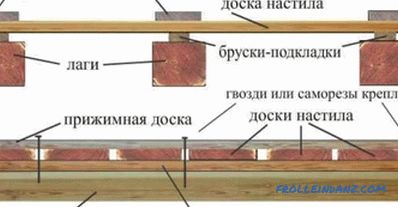

Table of the distance between floor lags depending on the thickness of the floor board.

To obtain a truly reliable mortar, it is first necessary to determine the amount of cement that is needed for screeding the floor. Initially, determine the strength that is needed, as well as under what brand concrete is produced.

In addition, it is very important to understand how much the solution will be used during the work. Once you get all the necessary data, you can calculate the weight of the substance.

After all the calculations have been made, you can start organizing the screed.

- The first thing to do is to prepare the surface. It is imperative to remove existing debris and dust.

- As soon as the surface is cleaned, it is covered with a layer of primer with deep penetration. The primer must be applied in two layers, the first one having to dry before the second one is applied.

- It is best to lay a polyethylene tape or other plastic along each wall. This is necessary to prevent deformation inside the material and to avoid cracks and chips.

- Next, fill and level the solution. It is best to fill in pre-mounted beacons. In their role may be trimming the profile for installation or the solution itself (or the logs themselves). Of course, it will take time to prepare the lighthouses, but in the future you will be able to save both time and material.

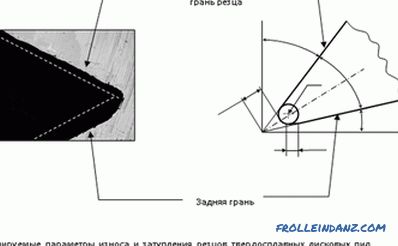

Organization of a cement-sand screed on wood logs

The cement-sand screed pattern on wood logs.

In most cases, the leveling mix is spread over the concrete base. But it happens that there is a need for arranging the screed on wooden lags (including in a wooden house). This situation is typical for the floor in a wooden house or for apartments in old houses. The whole difficulty lies in the fact that logs from wood do not have increased strength. Moreover, they can be damped by mechanical action, in particular, this applies to uneven loads.

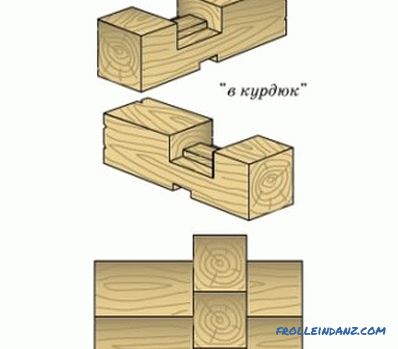

Therefore, there is a need to strengthen the construction of the lag. The density and elasticity of the solution must also be increased. It is possible to increase the elasticity with the help of special additives, in the role of which such substances as polystyrene, vegetable fibers, etc., can play. If there are two layers of reinforcement, the best option would be to make the frame from the channel.

Before the framework is installed, the gaps between the lags must be filled with insulation. In such a role can be expanded clay, perlite and other materials with a low thermal conductivity. Subsequently, the floor will be losing the least heat. Insulation gives an advantage in sound insulation.

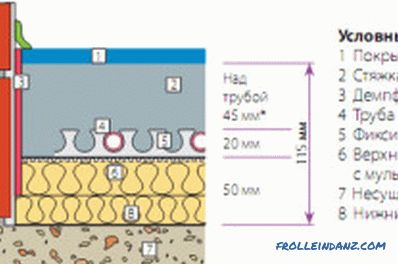

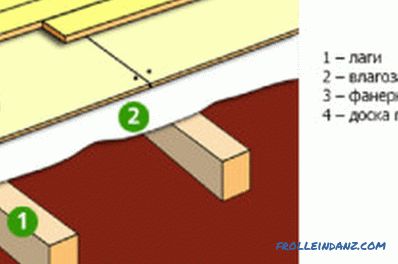

Floor cake on wooden lags with insulation.

After the insulation is filled up, you can begin to install the frame. Before laying the insulation on the base, it is necessary to spread a film of polyethylene. To lags attach channel with screws. After installation of the frame mount the reinforcing mesh in 1 or 2 layers. The grid should be located at a certain distance from the insulation. To correctly determine the distance, use clamps. On 1 square. m requires about 5 latches.

When the frame and reinforcement are installed, it is possible to fill the grout. As already mentioned above, it is best if the filling will be carried out according to the pre-set beacons. As soon as the mixture is poured, it must be leveled.

For this purpose, a vibrating rail is used. This tool removes bubbles from the uppermost layer, which increases strength. Next, you need to wait until the solution is completely dry and only after that it is ground. This process is needed to increase the strength index and create a more even surface.

Arranging the floor in a wooden house

Making a dry subfloor on logs.

Quite often, people living in a wooden house prefer a floor made of wood. In most cases, for the implementation of the planned pre-required installation of the lag. Lags are special wooden bars that are laid on top of the base. Only after that the final flooring is laid.

Nowadays, this way of arranging the floor is most often used in a wooden house.

How is the installation of dry floor on the logs in a wooden house?

Logs from wood are installed directly on the surface of the base. What should be the distance between the bars depends on the characteristics of the selected flooring.

If you plan to cover the floor with plywood, then the distance between the lags should be reduced.

The situation looks the other way around if solid wood boards act as floorboards.

Separately, it is necessary to say about the pleasant feature of a log of wood. It lies in the fact that this design can be installed on the base, made of virtually any material.

Arrangement of flooring by lags on a primer in a wooden house

Floor arrangement scheme for lags on a primer in a wooden house with moisture insulation.

- The first thing that needs to be done is to calculate the distance at which the lags will be and what is the distance between the supports. The distance depends on the thickness of the timber. The greater this value, the greater the distance can be.

- Columns for the foundation are used as the basis of the whole structure. They are buried in the ground, after which a waterproofing layer of roofing material and impregnated wood is laid between the concrete base and the ground layer.

- Brick columns are installed over the foundation pillars. Most of the underground reaches a height of 20 cm.

- A layer of insulation is placed between the posts (for example, expanded clay).

- After the heater has been laid, it is necessary to arrange impregnation with an antiseptic on it. She can be covered and the wrong side of the boards of the draft floor.

How to equip the wooden floor on the floor of reinforced concrete?

- The role of the base for lags in this case are pieces of fiberboard, which, in turn, must be impregnated with an antiseptic.

- The distance between the logs is not less than 60 cm. If you plan to use ceramic tile, then the pitch should be reduced to 30 cm.

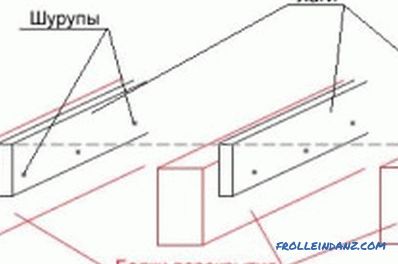

- The lag to the floor should be fixed with screws, screws and dowels.

- During the installation process, be sure to check the lag for evenness. For these purposes you will need a level.

Subtleties and tricks of mounting a wooden floor on logs

Lag installation scheme.

- In order for the finished wood floor to have an attractive appearance and to be visually perceived, it is necessary to position the bars perpendicular to the light from the window.

- In those places where people will move most intensively, the lags should intersect with the trajectory of movement, and the laid boards should lie along the movement of the stream.

- If you are arranging the floor along the logs in a city apartment, then under the uneven bars it is best to lay a sound insulation pad.

- In the process of work, do not forget about keeping the gap between the walls and the lags. Its width should not exceed 3 cm.

- If you prefer a tile made of ceramic, then while decorating the lag, take a step of no more than 30 cm. As a draft, it is best to use plywood, over which the gypsum plasterboard is laid.

- In order to increase the rigidity index of the subfloor, you can equip the lag structure in such a way that it will resemble a grid. The pitch will not exceed 1 m. This design is mandatory if laminate is used as a topcoat.

- As for such a flooring as parquet, it is better to install adjustable logs under it. The ideal horizontal level and the required ventilation are guaranteed.

So, you can equip the concrete screed and the wooden floor through the logs on your own, without the help of experts. The main thing is to do everything in order and not violate the previously thought-out technology.

Didn't find the answer in the article? More information on the topic:

-

How to build a house from a bar with your own hands?

Instructions on how to build a house from a bar correctly. Erection technology, tooling, preparation and calculation of lumber. Warming and finishing works.