Those who work with wood know how important circular saws are. This tool should always work properly and be in perfect order. It is known that any sharp-cutting tools have the ability to dull. Circular saws for wood are no exception. Sharpening them requires special attention. When the first signs that the saw begins to function poorly, should begin to sharpen, as in the future the tool will start to get blunt even more.

The sharpening of the circular saw is carried out in different ways: by file, by machine, in vice and by weight.

Circular saws for wood, sharpening of which is periodically necessary, is especially important when setting up a country house of wood. Circular saws are also called circular saws. This tool is important in that it can cut wood with high precision.

So is it possible to make sharpening yourself? Yes, self sharpening is possible. Timely sharpening circular saws on the tree will not only have on hand a sharp working tool, but also increase its service life. In particular, you need to monitor the condition of circular saws, whose power is relatively low, as a poorly sharpened saw begins to overheat. And overheating can completely disable the working tool.

Signs of deterioration of saw sharpness

When the following symptoms appear, sharpen the saw blade immediately:

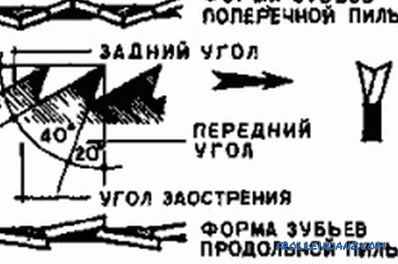

Circular saw tooth device .

- A noticeable increase in the temperature of the safety guard on the saw motor.

- Increased physical effort is required for cutting.

- Possible temporary smoke from the engine.

- The appearance of burning odor.

- The appearance of dark spots at the edges of the saw (carbon).

- The wooden bar does not move smoothly, but jumps around the machine.

- During operation, a suspicious noise is heard.

- There is a curvature of the teeth of the circular saw.

Work Requirements

There are also a number of work requirements that must be observed for safety and high-quality tool sharpening. When sharpening, the disc must be installed so that all the teeth are clearly visible. Only in this case high-quality sharpening can be guaranteed. The disc must remain in the same position during sharpening. It should fit very closely to the holding bars or grip.

In general, disc sharpening should be done on the machine. However, sometimes it is recommended to remove the disc and secure it in a vice. During the bending of the teeth you need to firmly secure the disk in a vice and use pliers. The angle of each tooth should be monitored all the time. If you do not observe the angle of inclination, the efficiency of the subsequent operation of the tool will be close to zero. Before you begin to turn down the teeth, you need to make appropriate notes on their original position.

Sharpening rules:

- First of all, care should be taken to remove metal evenly along the profile of the saw teeth.

- It is impossible in any case to press the disk to the grinding wheel, as this can lead to heat and heat the material, which leads to deformations.

- The profile and height of the teeth after sharpening should be maintained.

- It is also very important to use coolant when sharpening.

- It is impossible that burrs form during sharpening.

- As for the edges of sharpening, then in theory there is a rule: you need to sharpen either the front side of the teeth, or the front and rear. However, very often experienced masters sharpen it from the back side, because they consider that it is much more convenient.

Rules for setting the teeth

Rules for sharpening the saw blade.

Before you start sharpening a circular saw, you need to know that this requires wiring of the teeth. Teeth should alternately bend to the side and sharpen. However, it should be borne in mind that the bend of each of the teeth must be made at the same distance. In order to do this, use a special tool - wiring. With this tool, each tooth is retracted approximately in the middle of its height.

If the layout is correct, then the width is cut thicker than the saw blade. Proper sharpening assumes that the disk itself does not touch the material of the cut, and only the teeth layer by layer removed the surface of the tree. Therefore, the wider the layout of the teeth, the more volume will be cut and the less likely there will be a jamming. However, to achieve this effect is extremely difficult. Many begin to breed teeth with a key, but this method is completely unsuitable for costly quality saws. Therefore, you need to use only the tool that is designed for this purpose.

The type of wood that will be sawn also deserves special attention when sharpening a saw.For softer wood, a wider layout is required so that the cut is smooth and does not have rough edges and irregularities. The most optimal tooth deviation is 5-10 mm in one of the sides. The wiring must be done even before sharpening, as otherwise the teeth may be deformed and the saw will become unusable.

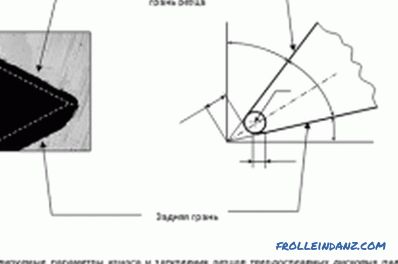

Circular sharpening scheme.

In total there are 3 main types of layout:

- Cleansing - with such a layout, every third tooth remains in its original position. This type is suitable for those cases when it is necessary to cut especially hard woods.

- Classic - alternately, the teeth are bent left and right.

- Wavy - with such a wiring, each tooth has its own position, as a result of which a wave of teeth is formed. This method is one of the most effective, however, and the most difficult. Experienced craftsmen leave a distance of 0.3-0.7 mm with this method.

Materials and tools used for sharpening

So, for work you may need:

- 2 bars;

- sharpened;

- vice;

- wiring;

- file.

Sharpening of the circular saw: the classical method

There are several different methods for sharpening circular saws, but the following method is a classic. Sharpen start from the back surface. The front end, which, when operated, runs over the material, remains in the same position.

In order to start sharpening a disk, you can either leave the disk directly in the machine or remove it from the machine and fasten it in a vice. In the first method, be sure to de-energize the machine by unplugging the power cord. To fix the disc in one position, 2 bars are used, which fix it as wedges. The bars should be pressed tightly against the teeth to avoid their movement. That tooth with which sharpening begins, needs to be noted by means of a felt-tip pen on lateral side.

While sharpening the first prong, you need to memorize the number of movements made with a grinding wheel or other tool.

All subsequent teeth should be sharpened with the same intensity and number of movements.

When working in a vice, the principle of operation is the same. Some more experienced craftsmen perform sharpening on weight, but for this you need to have a lot of experience. After complete sharpening the disc is inserted back into the machine. Next you need to cut some unnecessary wooden bar, while watching the work of the saw. It is necessary to pay attention to whether there are any extraneous noise and uneven movement of the beam. If there is extraneous noise or creaking, you must take a felt-tip pen and firmly fix it near the saw. Then slowly turn the dial. As a result, it will be seen where the height of the teeth is more or less than the rest.

Other sharpening methods

- Full-profile - is the most accurate and high-quality, as it is performed on a professional grinding machine. A special circle, which is selected in size, passes at once the entire interdental cavity along with the surface of the adjacent tooth. With such a sharpening, deformations of the teeth are excluded. The only disadvantage of this method is that different circles are required for different-profile saws.

- Sharpening the edges of the teeth - the convenience of this method lies in the fact that sharpening can be done both professionally and at home. If the work is performed on the machine, then you need to purchase special circles for different discs. However, it is still better to do work at home, as usually the amount of work is small and can be done using a regular file. For high-quality sharpening it is enough to make 4-5 movements with a file - and the tooth will be sharp.

A few tips from experienced craftsmen

Safety goggles should be used during work. When grinding, remove only the amount of metal needed to completely remove cracks and deformations. When grinding, the disc must remain all the time in one position relative to the machine.

With a long absence of sharpening, more material must be removed. The shape of all the teeth should be exactly the same, as well as the height. All remaining burrs must be completely removed.

Didn't find the answer in the article? More information on the topic: