To get into the interior of your own house, you need to go through the porch. Without this extension, the house or cottage does not look quite finished. The porch performs several functions: aesthetic, the function of entering and leaving the house, protecting the house from winter drifts. To build a wooden porch with your own hands is not the most difficult task. By its construction it can be simplified, built-in, attached. Less commonly found porch-patio and other original forms.

By design, the porch can be simplified, attached or embedded.

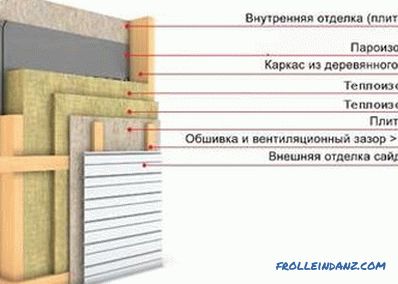

The design drawings for a wooden house under construction usually include the drawings of a porch with your own hands, from which, if desired, you can move a little. The porch patio is an intermediate option between the terrace and the ordinary porch. Its design is quite simple, but functional. This building is ideally suited to a wooden house located in a warm climate, where there is no snow. But such structures are erected in regions with precipitation in the form of snow. In this case, outside the wooden porch is recommended to finish with additional siding. You can build it without any problems.

Materials and tools

For work it is necessary to prepare the following materials:

- pine log or bar 100x200 mm;

- boards for the manufacture of steps, platforms , side racks and railings;

- 50x150 mm boards for building a roof over the porch.

Tools needed:

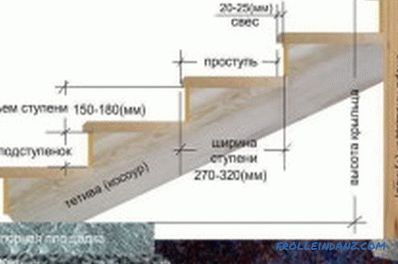

The size of the steps for the porch.

- hacksaw;

- hammer;

- shovel;

- level;

- nails and screws;

- screwdriver;

- tape measure;

- pencil.

Construction of the porch

The construction procedure includes the following main steps:

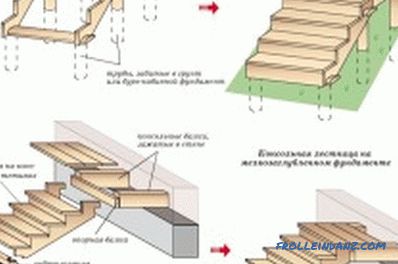

Stage 1. For the construction of a wooden porch is required to equip the foundation. The optimal choice of its design is considered the pile option. It is characterized by simplicity of construction and low cost. Pine timber from which supports will be made is treated with an antiseptic composition. A pit about 80-100 cm deep is dug out for the installation of each support. You can drill it with a drill of the required diameter. The lower part of the pillars is processed with hot bitumen, wrapped with roofing felt, installed in a pit, filled with soil and compacted. Instead of bitumen, used and waste oil. It is possible to fill the supports with concrete. Installed pillars must be trimmed so that they are the same height.

Schemes of stairs for a porch.

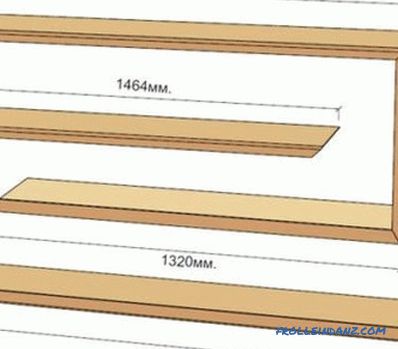

Stage 2. It is necessary to make a string and kosoura. The simplest string is the ledges carved on it. The variant with the steps cut into the string is more complex. The notches under the steps can be marked with the help of a piece cut out of cardboard in the form of a right-angled triangle. Its legs are equal to the size of the tread and the riser. The tread is called the horizontal part, the riser is the vertical part.

The recommended tread width is 37-45 cm, the height of the steps (risers) should not exceed 20 cm. The porch of a wooden house should have an odd number of steps. The width of the porch should be one and a half width of the door, to which the porch is adjacent. Marked parts are cut with a hacksaw or jigsaw. The finished elements are aligned with the level and attached to the upper end of the supports. For stronger fastening of all elements of a design use steel brackets and metal strips.

Stage 3. All work on the installation of flooring, steps and risers is carried out, and the railing is installed. These parts are fastened in different ways: with the help of grooves and spikes, nails, screws, screws.

The service life of a wooden porch depends on many reasons. Not least among them is the quality of materials. The tree should be well dried. In order to protect against decay and from various pests all structural elements must be treated with antiseptics.

Ladders on different types of supports.

Stage 4. Erection of a visor or roof over the porch. This detail is able to give the whole country house a complete aesthetic appearance, to protect the porch of a wooden house from the effects of precipitation. On the visors look good jewelry made of carved wood and metal forging. The shape of the visor, its color and material usually repeat the corresponding parameters of the main house. But this is not a prerequisite. Most often, the roof make a shed with a slope of the slope away from the house. As the material used traditional metal, slate, corrugated.

The roofs and canopies of colored polycarbonate sheets look quite effective. They easily take any form, differ in ease of installation and small weight. For their construction are installed additional wooden or metal racks. You can simply attach to the wall frame, welded from metal.You can use a frame made of aluminum profile. The dimensions of the shed above the porch usually do not exceed 100x200 cm.

Possible errors in construction

- The staircase attached to the house is attached close to the door. Frozen ground in winter can lift the entire structure. As a result, the front door can open with some difficulty or be completely jammed.

- The pile foundation is not deep enough or is not processed by bitumen. This will lead to the decay of wood and the gradual destruction of the structure.

- It is recommended to install a wooden porch 10 cm below the door leaf, and install a threshold in the doorway. These measures will prevent the onset of many possible troubles during the operation of the porch.

A few useful notes

The porch made of logs fits perfectly into the ensemble of wooden houses.

- The wooden porch is the most common type of such structures. It is great for houses made of logs, lumber and adobe. They are often trimmed with vinyl siding.

- In modern construction, instead of traditional logs, bars of different sections are usually used. An ideal material for the manufacture of bars, of which build a pile foundation, larch.

- You can decorate the porch for a wooden house with your own hands, making it especially attractive, able to charm guests who come into the house.

- Without proper care, protection of structures from mold and insects, a wooden porch can quickly lose its function and presentable appearance.

- If you plan to build a roof or visor over the porch, this building should be 20-30 cm above the entrance door.

- The area under the porch can be concreted in a layer 10-20 cm thick. strength.

- It is possible to build a porch of rounded logs by inserting steps of thick boards or of sawn along the same logs between them. For such a construction would require the construction of strip foundations.

- A lot of money is spent on building a country house, as a result of which they may not be enough on the porch. In this case, you can build a simple porch with the use of residues of boards and boards after the construction of the house.

- Railing is recommended to be installed with a porch height of more than 1.5 m. The optimal height of the railing is 80-100 cm.

- The internal volume under the porch can be used for household needs. For such use, you need to enclose the porch from all sides with boards, chipboard, other materials. It is necessary to equip a small door through which you can get inside the under-cover space.

Building a porch of any type for a wooden house with your own hands is quite a task.

To complete it, you need a minimum of tools. For the manufacture of the porch, you can use the trimming of materials remaining after the construction of the house. You can decorate the finished structure with wooden carvings, wrought metal elements. The main thing is to process all wooden parts with hot bitumen, antiseptic agents. This will significantly extend the service life of the porch.

Didn't find the answer in the article? More information on the topic:

-

Properly making your own shelves

Making your own shelves: planning, work features. How the appearance of the front edge made affects the shelf rating. Wood shelf processing, assembly work.

-

Frame house: we build with our own hands

How to build a frame house with your own hands: the device foundation, frame, floor, walls, roof. Carrying out wall insulation, installation of windows and doors in the house.