It is nice to get out of the hot steam room and dive into the cold water. To make this a reality, you can make a small pool with your own hands. Certain types of construction are easy to assemble yourself in the yard at the cottage or at home. This article will help the owner to please his family, you just need to make the most of those materials that are already in stock.

Types of pools

In order to have something to choose from, it is necessary to know about the features of various solutions and their relevance for specific conditions.

Inflatable

Inflatable

Inflatable pools. Such products are installed in less than an hour. The pool usually represents capacity which is made of PVC of a film. In order to avoid breakthroughs and the pool served for a long time, it is reinforced with additional polyester fibers. Inflatable is only one part - the upper edge. The whole scheme operates on the float principle. Water starts to dial inside, the side pops up. As the level of the wall increases, a full bowl is formed. Included are usually a pump, filter, ladder and assembly instructions. Of the positive qualities can be identified:

- high assembly speed;

- relatively low weight;

- reasonable price;

- possibility of deployment in any conditions ( the requirement is only sufficient rigidity of the base and its evenness).

An inflatable pool usually meets all intended requirements. But you should be aware of certain shortcomings: a high probability of water pollution, the relative fragility of the material (a fallen heavy branch or a sharp object can damage so much that you have to make a full replacement). The price of such products can not be called low, for some samples it will be necessary to lay out 30 thousand rubles and more.

Frame

Frame

Frame. Among the pools of this type there are a large number of different solutions. In the role of support can be metal tubes that are assembled into a closed structure, and a PVC bag is placed inside. When it is filled with water, the walls rest against the racks and their expansion is limited. Shield skeletons are assembled from individual sheets of metal, which has an anti-corrosion coating, which prevents its damage. The interior space is organized in the same way as in the previous version.

The installation of a frame pool usually takes a whole day. At the same time, he also needs a good foundation so as not to deform it with the weight of the water poured. Seasonal containers will have to disassemble the fall and re-install closer to the summer. There are those who can safely spend the winter. Usually they have additional stiffeners, and the main racks are large. This is necessary in order to resist the action that will occur when water freezes. Such pleasure will cost more than inflatable counterparts.

Fiberglass

Fiberglass

Fiberglass. In most cases, this design is a finished cast container. It has specified parameters: depth and capacity. Nothing to invent. It will only be necessary to dig out the corresponding trench, install the capacity and bring the required communications. One of the advantages is the high strength of the product. By some indicators, it even surpasses the concrete. Due to the properties of the components, the bowl is not exposed to linear expansion due to temperature fluctuations. This means that the service life can be very long with proper maintenance. Fiberglass is perfectly repairable. The walls are so smooth that the garbage simply cannot linger on them, which means that they are very easy and simple to clean. A large number of additional equipment is available, for example, you can buy a variety of slides or jumps for jumping. This will please not only children, but also adults. The low level of thermal conductivity prevents the rapid cooling of the heated liquid.

Polypropylene

Polypropylene

With a polypropylene bowl. By itself, this polymeric material has sufficient strength. He does not need an additional layer of waterproofing, which will prevent the outflow of fluid. Most often for the manufacture of such options are used blanks in sheets. They are blue or cyan. The assembly can be done by yourself, but for this you will need certain tools. Most often this is entrusted to professionals. The construction of the entire structure can take from several days to weeks. Such pools have a recessed structure, so large scale excavation is required, as well as the laying of a concrete base plate. The material is resistant to ultraviolet and chemically active substances. Because of this, it can be easily located in the open.

Concrete

Concrete

With a concrete base. To put it simply, this is the pit of arbitrary length, width and depth chosen by the user. It is filled with a solution. Walls and bottom can be lined with special ceramic tiles or mosaics. Implement such a project can almost everyone in any suitable place. For such a pool, it is important to think over all the required communications so that it serves as long as possible.

Dome

Dome

Dome. It can be any of the listed options. A special feature is that they all have a roof. It can be made from various materials. The main highlight is that the bowl is closed on all sides, which prevents the wind from blowing, and also contributes to the rapid heating of the water inside.

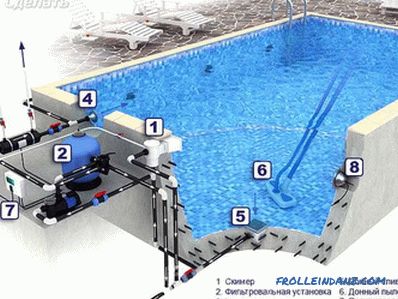

In addition to the differences in the method of erection, subspecies are also distinguished according to the filtering variant. These can be:

- Skimmer. In this case, water is withdrawn from the pool through technological openings that are located on the side walls. Moving through the channels, it gets into the filtering device. It is cleaned, disinfected and partially heated. Return to the tank is through nozzles.

- Overflow. This method is more spectacular, but also costs more expensive in construction. A mirror of water comes to the top of the pool. Water flows through the drain hole or the upper side and enters a special chute, and from it into the tank. In the latter there is a pump with a water sensor, which pumps the fluid into the filter, where it is being cleaned. Back the liquid flows through the holes that are located at the bottom of the pool.

Skimmer

Skimmer

Overflow

Overflow

Choosing a place

In addition to choosing a pool and even before creating its drawing, it is important to think about where to place it in your plot. To make it easier to decide on this, here are some rules to consider:

-

We need an open area Large vegetation. Greens and trees are always good. But for their life requires moisture, which they absorb through the leaves and root system. In the period when the water will not be enough, they will try by all means to move to its source. As it grows, the bottom or walls of the pool can be damaged, which will cause the outflow of fluid. Therefore, it is very important that such vegetation is not close. In addition, in the autumn period, the foliage will fall to the bottom and promote the formation of algae and silt.

We need an open area Large vegetation. Greens and trees are always good. But for their life requires moisture, which they absorb through the leaves and root system. In the period when the water will not be enough, they will try by all means to move to its source. As it grows, the bottom or walls of the pool can be damaged, which will cause the outflow of fluid. Therefore, it is very important that such vegetation is not close. In addition, in the autumn period, the foliage will fall to the bottom and promote the formation of algae and silt. - Wind direction. If the basin is rectangular, then its position should be such that the long side is along the direction of the average annual wind movement. This is done in order to properly install a filtration system, the fence for which will be carried out at the far edge, where all the garbage will be collected.

- The proximity of communications. If you plan to install a stationary version, then it is very important to consider this factor. This will avoid digging a large number of trenches and laying pipelines.

- Relief. The most convenient way will be to work on a relatively flat area. Thus, it is easier to sustain the required level, and you can also be sure that the soil will not be sprinkled from the walls. The sides of the future structure will also be uniform. But a small bias will still help in the organization of drainage.

- Need for drainage. In some areas, groundwater is very close. When installing a submerged pool during construction, liquid may accumulate in the pit, which will impede rapid progress. Therefore, it is worth picking up a site where there is no difficulty.

High ground waters

High ground waters

Frame assembly

Such a variant can do very cheap to manufacture. In order to realize it, you will need a bar of 100 * 100 mm, an edged board of 100 * 30 mm or 50 * 30 mm. You will also need a material that has good waterproofing and is able to withstand high tensile pressure.

Assembling a frame pool of wood and PVC

Assembling a frame pool of wood and PVC

- The site is selected as described above .

- A pit is dug 40 cm deep. Its dimensions should be 20 cm larger than the size of the planned basin.

- The bottom is well packed.

- A small slope is created towards the middle, where a small hole is excavated with dimensions of 50 * 50 cm and a depth of 20 cm. It will serve to collect water, which may overflow the edges.

- All space is filled with rubble of medium or small fraction. The layer should be 20 cm.

- Another 20 cm is sand. It is very important to tamp it well, so that the pillow is tough enough.

- The plane is displayed using beacons. This will allow the pool not to twist. In the role of guides can be metal pipes or wooden beams, which are laid using the building level.

- Racks are made of the wooden timber mentioned above. Their number should be such as to install through each meter. The total length equals the height of the pool plus 50 cm, which must be immersed in the ground.

- The part that will be in the soil is processed using bitumen mastic or wrapped in roofing material. In addition, it is necessary to cover the tree with an antiseptic composition so that rot from constant exposure to moisture does not occur.

- A pit is dug to a depth of 50 cm at the site of installation of each column.

- Corner posts are mounted. They are aligned with the construction level in the horizontal and vertical plane.

- The space around them is filled with sand and soil, which are well tamped to securely fix the element.

- The diagonals are checked to make the construction symmetrical.

- The fishing line is pulled between the posts. One should be at the bottom, the second at the top. They are necessary in order to facilitate the installation of the remaining reference points.

- The remaining parts are mounted with the specified step.

- With the help of the trimmed board, the supporting walls are packed. Elements are better positioned closely to create a uniform plane.

- After the frame has been manufactured, the material that will serve as a receiver for water is placed inside. This may be a dense plastic film. It is important that it be in one piece, since a leak will necessarily appear at the site of the seam, and water will seep into the ground. The edges must be wrapped over the top edge so that the material does not crawl during operation.

- If you wish, you can make a more durable option. To do this, you need a PVC base, which is used for sewing awnings for trailers, eyelets, riveters, construction hair dryer and rubber roller. The blanks are placed inside the frame and the markings are made, what bends will need to be made in the corners, how much should be left for turning, exactly where the seam soldering will be made. Separate sheets are interconnected with hot air. They are stacked with a small overlap. By means of the hair dryer the warming up is carried out to almost full softening. Rolling roller formed spike. This should be done on a flat surface without debris and dust. The top edge is bent by 5 cm. The grommets are installed with the help of a riveter. The distance between them should be 15 cm. Fixing the awning can be carried out to the inside. To do this, he simply presses a screw with a washer to a wooden base. Either the edge is bent over the top level, then a rope is pulled through the grommets and it clings to the prepared elements.

- The finished pool is filled with water.

Assembling the purchased frame pool

Assembling the purchased frame pool

To make the design easier to fit into the surrounding exterior, it can be partially or completely immersed in the pit. In this case, the bottom is organized in the same way as described. Drainage system can be improved. To do this, a sewer pipe is fed to the pit, which is located in the middle, the second end of which goes into the water collector or canal. Thus, water will be drained much faster.

Production of a concrete pool

Pit for a concrete pool

Pit for a concrete pool

Basic the task for such an option would be earthworks. Having defined the place and having marked the territory, a hole of the required depth is dug out. The bottom is formed in accordance with the recommendations listed above.

- The next step is to dig a trench. It should connect the pit to the groundwater drainage site.

-

Construction of a concrete basin Inside the recess, which is made in the middle of the pit, a pipe is laid. It is discharged through a trench to the place of collection of liquid.

Construction of a concrete basin Inside the recess, which is made in the middle of the pit, a pipe is laid. It is discharged through a trench to the place of collection of liquid. - The surface is covered with a layer of gravel.

- Ladders are installed at the site of the planned location of the drain holes. To them the eyeliner from polypropylene or other pipes becomes. They are wrapped in oilcloth to prevent concrete from falling into the middle.

- A reinforcing mesh is laid on the bottom. It is made of reinforcement with a diameter of 12 mm. It is necessary to slightly raise it so that all the rods are subsequently completely immersed in the solution. To do this, you can score posts from scrap materials.

- Additionally, you must install vertical bars, which will later ensure a good connection between the bottom and the walls.

- Mortgages are made - these are wooden boxes, thanks to which you can leave technological holes.

- It is better to order the concrete solution ready from the manufacturer.This is necessary in order to simultaneously fill the entire space. If the preparation will be carried out manually, then you will need several large concrete mixers. Cement must not be used below grade M350.

- The territory is carefully filled. After that it is necessary to make consolidation by the vibrator. The final touch will be the alignment using the vibrating rail or rule.

- In this condition, the resulting plate must be left for 2 weeks.

-

Foam block pool You can start building walls. They can be cast as monolithic, but it will have to make a lot of effort to exhibit formwork. Another option would be the use of hollow polystyrene blocks or foam blocks. They must be laid in such a way that the fittings, which were installed vertically, pass through the holes of the stone. Subsequently, the concrete solution is poured inside. In the course of laying it is necessary to provide for the presence of technological holes for lighting devices, as well as for the skimmer.

Foam block pool You can start building walls. They can be cast as monolithic, but it will have to make a lot of effort to exhibit formwork. Another option would be the use of hollow polystyrene blocks or foam blocks. They must be laid in such a way that the fittings, which were installed vertically, pass through the holes of the stone. Subsequently, the concrete solution is poured inside. In the course of laying it is necessary to provide for the presence of technological holes for lighting devices, as well as for the skimmer. - Next, apply the plaster with a layer of 1 cm.

- After drying, all the planes are carefully rubbed. At the same time, care must be taken to avoid large scratches that could later damage the waterproofing.

- In the case when the walls were made of stone, the outer side of them should be glued with foam plastic and tightened with waterproofing. The latter will not allow moisture from the outside to destroy the material, and the insulation will serve as a compensator for thermal expansions.

-

Waterproofing of the pool The entire interior space is covered with a special waterproofing compound. Next, apply the polymer composition, which will provide full impermeability. It needs to be cleaned up as soon as it grabs, since then it will be much more difficult to do.

Waterproofing of the pool The entire interior space is covered with a special waterproofing compound. Next, apply the polymer composition, which will provide full impermeability. It needs to be cleaned up as soon as it grabs, since then it will be much more difficult to do. - Laying a mosaic or tile. It should be glued on a special polymer mixture, and not on ordinary tile glue.

- The pool is being filled. In this state, he should stand for 2 weeks. If the water level is kept, then it can be cleaned, connect all the required elements, add an antiseptic and use.

Installation of the pool of polypropylene

Pool of polypropylene production

Pool of polypropylene production

With certain skills, installing such a pool does not take too much time. We will need sheet polypropylene (wall thickness from 8 mm), material for joining, a technical dryer, a plane.

- The first step is to prepare the bottom. For this, the sheets are laid out on a flat surface.

- With the help of a planer, a chamfer is removed at an angle of 45 ° at the end, which will be glued.

-

Installation of the pool The two elements fit closely together.

Installation of the pool The two elements fit closely together. - A special nozzle is attached to the hairdryer, which has a narrow nozzle, as well as a special paddle to feed the PP tape.

- Gradually warming up, the cord fits into the prepared groove between the two sheets.

- After the seam has cooled down, the projecting part can be removed with a chisel.

- The finished bottom can be set aside. The next step is to install stiffeners for the walls of the pool. For this, strips are cut. Their length should be 20 cm less than the height of the pool, width - 15‒20 cm. They should be glued butt to the outer part of the wall by the same method as described, but without chamfering.

- The final step will be gluing the walls to the bottom.

Stiffeners

Stiffeners

For the installation of such a construction, a ditch is prepared, its dimensions must be larger the product itself is 10 cm on each side. The bottom has to be filled in with solution and constantly. The vessel is immersed in the middle. Gravel is poured into the space between the walls of the vessel and the pit and is well rammed.

Polypropylene pool manufacturing technology is shown below:

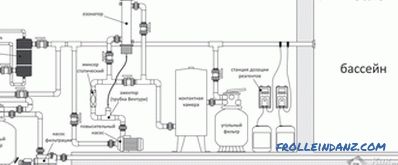

Filter system

A filter for a pool is an essential device that must be present. Without it, it will not be possible to use water for a long period of time. It will require frequent replacement. The device can be installed near the pool itself, as well as in a specially prepared place. There are a large number of ready-made options. For a small pool there is no need to take too powerful filter. If desired, you can collect it yourself. To do this, you need a plastic barrel of 100 liters. The main condition is the presence of a cover that can be closed tightly. A centrifugal or drainage pump, plastic pipes, fittings, and a filter cartridge will be required.

Filtration system

Filtration system

- A hole is drilled below the tank neck.

- A threaded nipple is inserted into the hole. Sealing rubber bands are put on both sides and lock nuts are screwed on.

- The same output is made 5 cm above the bottom diagonally.

- A pipe is connected to the upper adapter, which will take water from the pool.

- A filter cartridge is put on the lower inner side. From the external pump is connected. From the pump is the conclusion to the pool.

- Half coarse sifted sand is poured into the barrel.

- The installation must be below the water level in the pool. Liquid will flow into the tank by gravity. Passing through the sand, cleaned and fed back into the bowl with the help of a pump.

With the right approach to business, the pool will serve more than one year. Concrete or polypropylene construction can be easily made in the bath or basement of the house. But this should be planned at the construction stage in order to avoid unpleasant consequences from uneven load.

Video

Below you will see a video instruction on the construction of a concrete pool:

Photos

Small pool in the backyard

Small pool in the backyard

Ready tank for the pool

Ready tank for the pool

PVC pool installed in a concrete bowl

PVC pool installed in a concrete bowl