The main purpose of a circular saw is to cut such materials as: boards, soft metal, laminate, cant, drywall, etc. Due to its power, this tool is almost indispensable where precise longitudinal and inclined cutting is required. However, the principle of a circular saw has only one drawback - it is the impossibility of obtaining a cutting line of curvilinear shape due to the limited scope.

The main purpose of the circular saw is to cut various materials: boards, soft metal, laminate, beam, drywall, etc.

It is necessary to take into account one very important rule - despite the power of this device, it is forbidden to work with steel and other ferrous metals with the help of it . Circular saw is indispensable when building with your own hands. In addition, it is often used in carrying out repairs in the house.

If you decide to put laminate flooring in your apartment, sheathe the walls of the balcony with panels, repair the floors or ceilings with your own hands, keep in mind that you cannot do without a circular saw. With it, you can achieve the most accurate and accurate cuts. With large sawing volumes, the use of jigsaw is inappropriate, and the chainsaw will not be able to provide even cuts.

Design features of circular saws

The design of any circular saw is based on one similar design. Differences in this may be such qualities as:

The layout of the circular saw.

- performance;

- additional functions;

- drive power;

- slice thickness.

With the help of additional functions, the area in which the circular saw is used can expand considerably. Such a tool is characterized by increased security, and working with it is usually much easier and more convenient.

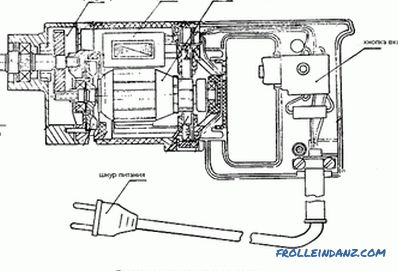

As for the device of the circular saw, it is presented in the form of a flat bed equipped with a drive, on which the cutting disk is mounted in a vertical position. Also on the saw there is a handle with a button for starting up and several auxiliary devices, which include:

The circular saw must be held very tightly at work.

- nozzle, which performs the function of removal of sawdust;

- ruler guides;

- hinge devices, with which the material can be cut at a certain angle.

Cutting is performed by pressing the frame against the panel (or some other material). The disk, which rotates up to 5000 rpm, begins to cut the material.

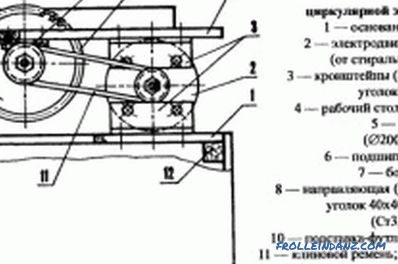

3 main categories of the device of circular saws

- With an electric motor power from 0.8 to 1.2 kW. The material for cutting in this case may have a thickness of not more than 45 mm. The diameter of the cutting discs of such a tool can be 130-160 mm. For cutting material with a complex texture, this device is not suitable. Its cost is quite small.

- With an electric motor up to 1.8 kW. As for the depth of cut of such a device, it does not exceed 60 mm. Diameter of circular disks of a saw not less than 200 mm.

- With an engine power of 2 kW. This device is equipped with cutting discs with a diameter of up to 350 mm. With the help of such a device it is possible to cut sheet metal. In most cases, the device of such saws has the function of stationary attachment to the workbench, which greatly facilitates many tasks of users. As you understand, the cost of such an instrument is quite high, but the professional level it possesses is worth it.

Basic requirements for a circular saw

When choosing a circular saw, attention should be paid to the presence of such frequently encountered additional (useful) functions such as:

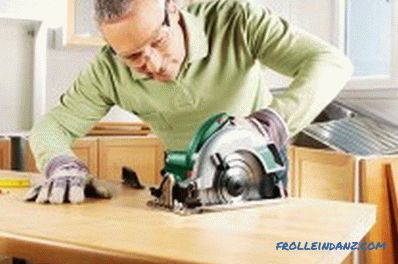

When using a circular saw, you should protect your eyes with glasses and your hands with gloves.

- Ability to adjust the speed of rotation of the disks. Keep in mind that the method of implementing this function can be of 3 types: mechanical and electronic. To achieve perfectly smooth and neat cuts (without the presence of a burr) is possible only by adjusting the speed of rotation of the discs, since each material requires a perfect approach. This type of tool is universal in its application.

- The function of immersion in the material when sawing. This quality is a great advantage of the tool. In particular, it is convenient in the process of sawing whole slabs. Due to the ability to offset in the vertical plane of the disk of such a circular saw, it is possible to cut the material immediately from its middle.

- Ability to quickly stop the rotation of the disk. This quality tool provides a safer work process.

- The presence of the built-in illumination and laser markings will make your work more comfortable and safer.In addition, thanks to these functions, the cut will be as accurate as possible.

- The soft start function of the rotating disk can also significantly increase the level of safety, since the possibility of a dynamic jerk is eliminated during switching on of the tool. In particular, the presence of this function is desirable for devices equipped with powerful electric motors. In addition, the mechanics of the tool and the electrical network are subjected to significantly less load.

The device of saws, equipped with powerful electric motors, has special elements designed to be mounted on a surface convenient for the job. This ensures the immobility of the tool. As for the sawing, in order to carry it out, the material is fed directly to the rotating disk. The presence of such a function greatly facilitates the user's work, especially if he is faced with the task of cutting a very large amount of material.

A bit about circular saw blades

For different materials it is supposed to use different discs.

The technical parameters that may differ with the circular saw blade include: the height of the teeth, their frequency or number, the geometry of the sawing profile, etc. The discs can have 2 main purposes:

- for working with soft materials;

- for working with metal.

In the first case, a positive sharpening angle is provided on the disks, in other words, the teeth are tilted in the direction of rotation. Metal cutting discs are manufactured with a negative sharpening angle. Their teeth have carbide soldering, which are tilted in the opposite direction of rotation. In a wide range of stores you can find discs specifically designed to work with a certain type of material (for example, for cutting laminate or plastic).

When compiling discs, several basic rules should be considered:

If the teeth on the circular saw disc are sparse, then the cut should be more ragged.

- In order for the cut to be as accurate and even as possible, it is recommended to select a disk with a large number of teeth. This tip only applies to soft materials.

- If the disc has sparse teeth, the cut will be more ragged. This disc is designed to work with resistant, solid materials.

- In order to accurately cut the board or chipboard, you should use a disk that has often spaced teeth, which number is about 100 pcs.

To work with wood that has a large number of hard knots, it is recommended to use a reinforced disc that has a minimum number of teeth - about 24 pcs.

As you understand, to get a smooth cut in this case will not work.

The designation of the size of any disk for a circular saw is always the same way. As a rule, this is the presence on its surface of 2 digits, which indicate the diameter of the disk and the diameter of its hole, intended for the mounting sleeve (for example, 160 x 30). Accordingly, when buying a disc for a circular saw, you need to know the size you need. It should be noted here: the installation of disks of smaller diameter, that is, those that do not provide for the construction of the tool, is not strongly recommended. Otherwise, there is a risk that a finger may get into the gap, which forms a protective casing, and the disc during operation.

How to choose the right circular saw?

When choosing difficult and dangerous electromechanical tools in operation, it is very important not to lose sight of any detail. Inspect the device as carefully as possible and get detailed advice from the seller on the operation of the tool. Save in this case is not recommended. When buying do not forget to get a guarantee on the reliability and safety of the circular saw.

A little about basic safety measures

When cutting material, it should be securely fixed. In no case the included tool do not turn the rotating disk upwards.

Before applying a disc, make sure that it is suitable for working with the material being cut. In carrying out the work, you must wear special safety glasses that will help protect your eyes from flying sawdust.

Didn't find the answer in the article? More information on the topic:

-

How to choose the right saw

How to choose a circular saw: the main parameters of modern tools. Selection of saws for cutting disc diameter, power, additional mechanics and electronics, ergonomics and other characteristics.

-

What house fretsaw is better to choose

Which jigsaw is better for home use? Attention should be paid to the functions of the tool.Estimated power equipment, the ability to adjust the course.