Interior doors add completeness to the interior of any room. Skillful selection of doors is not so easy to do, given that the market for these products is saturated to the limit. There is a peculiar absurdity of the situation: the huge amount of the goods offered creates the illusion that there is still no necessary goods. Psychologists explain this by saying that you automatically compare ideas for the performance of a single product with other proposals and want to combine several of your favorite options in a single product. The very idea of combining and should lead to the idea that interior doors can be made independently.

After you have thought through the design yourself and made the necessary measurements and drawings, you can start making a wooden door with your own hands.

And why not? We take a pencil in our hands and begin to invent our own design. This will be the main stage in the manufacture of doors with their own hands. Do not be surprised that even your own idea, embodied on paper, can not cause excitement either to you personally or to your family members. Creating is always difficult.

Necessary tools and materials

Several design options will precisely lead you to the right direction, and you will get an idea that you want to perpetuate in material form. We start making the conceived door. The easiest way is to contact an experienced carpenter. By the way, not every master will begin to fulfill your order: an unusual or non-standard product requires careful study of all the details, and not everyone wants to do this. Yes, and such services will cost too expensive. But do not despair and stop halfway. Interior door can be made independently. To do this, you will need:

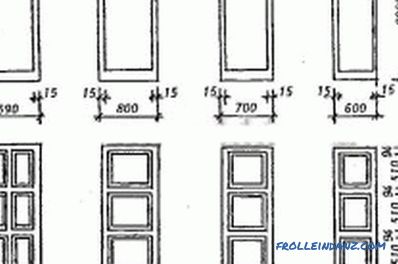

Views with the dimensions of interior doors.

- lumber;

- ruler and square;

- circular (milling machine for wood);

- reinforced glass (if the doors assume him);

- electric planer;

- grinder;

- drill;

- chisels and hammer;

- wood putty and rubber spatula small size;

- brush and varnish.

Your main task will initially be to prepare high-quality material. Wood (meaning lumber) must be chosen dry, without damage and bends. All the material you must carefully process: cut, planing, grinding. The prepared material is subject to markup. It’s good to have a complete product map on hand, which would significantly speed up the entire process. And so you have to work on the principle of "measure seven times - cut once." Inexperienced master can be recommended to initially consider and make the body of the future door. The most difficult will seem the articulation of parts into a coherent whole.

Subtleties of assembly and fastening

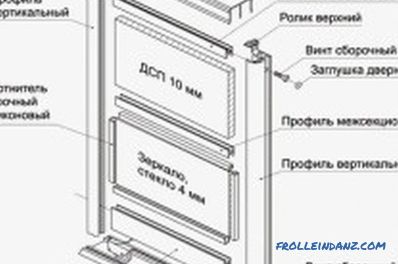

Hinged door assembly scheme.

It is not recommended to use metal corners for fasteners. The connection can be no less reliable and more beautiful with the help of the old ways. To do this, cut the end parts of the vertical and horizontal blanks (twice) across the entire width of the blanks to a depth equal to the width of the blanks themselves. It turns out that the end part of the workpiece is dissolved in three equal parts. At the horizontal part, we cut off the two outer parts of the board, and at the vertical part we gouge out the internal part with a chisel. Now try to connect the details. With proper performance of work and accurate markup, you will get a very good (externally) connection. It is not firmly held yet, as there is still to be made through holes in the junction and to plant parts on wooden studs.

Although this option of bonding is also less and less used in practice. Compounds on wood glue or fastening with a wedge driven into the inside of a horizontal part remain more popular. Even without these methods, you can get along fine if you think over all the details of the technology in advance and take them into account when sawing the ends of the blanks. Then the connection itself will be tight and reliable.

Production of paneled door.

All parts of the door need to be interconnected by one of the methods described earlier. Fix all finally not in a hurry. Details of the inner part to be carefully adjusted to the size of the resulting frame. About the connection of these parts among themselves and with the outer frame of the door should be thought in advance and give all the details necessary profiling. When all the parts are ready, they can be joined together. Joiner's glue is suitable for this well, but in most cases more modern tools are used.

Drying and decorating

We leave the interior door to be dried for at least a day. To dry the product must be in a horizontal position in a ventilated room.And after that, the door must again be carefully measured and a perimeter walk along the plane, especially if the angles are not entirely straight or there are differences in size. Fit to the required size, you will be able to cut off the extra part of the tree.

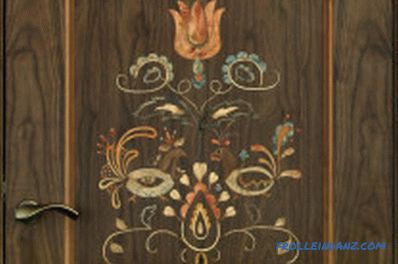

The assembled and installed door can be beautifully decorated, for example, with a painting.

And now you have to finish the interior door decoratively. Here, personally, your ideas will work. Perhaps it will be wood carving, perhaps the usual processing of wood stain. The main thing is that the interior doors in the room like you and your family. Wood lends itself to any kind of finish, so create. Before covering the product with varnish, it is necessary to seal all cracks and irregularities with the help of special putty for wood and once again carefully sand all surfaces. Varnish for the interior door is better to choose matte and apply it in two or three layers with an interval of 1 hour.

A self-made interior door will not look quite harmonious if the doorway, including the door frame, is made of factory-made parts.

Therefore, installing your product right away will fail. It will be necessary to make the mentioned parts in the same design with the door and to make an opening with them. Only after that you can equip with a chisel, a hammer and make recesses for door hinges on the doorposts and on the finished interior door. Ideally, even if the door hinges are made independently. Then surely everything will look like a single ensemble.

When installing the door, it is recommended to use the building level. If the door is incorrectly positioned, it will open (or close) on its own, which is also undesirable. Proper installation of the door does not complete all the work. Install the necessary and other accessories: handles, latches, locks.

Didn't find the answer in the article? More information on the topic: