Concrete mixers actively use in their work not only professional construction teams, but also home craftsmen who use them to carry out both large and small construction work. At first glance, it is very difficult to determine which concrete mixer is the best of those sold in hardware stores. In this material we will try to answer this question by comparing the technical characteristics of these devices, their advantages and disadvantages of specific models.

Which is better forced or gravity type concrete mixer

To understand which concrete mixer is better to buy, you need to define several positions:

- For what purpose and under what conditions will the device be used;

- How much concrete should be obtained in one batch;

- What type of mixture should be obtained (liquid and soft or thick and tough).

All concrete mixers are divided into two types according to the principle of operation: forced and gravity. Some are more suitable for large-scale construction, others are more convenient for homework. Consider in detail each type.

The principle of operation of forced concrete mixers

In forced concrete mixers, the drum does not rotate, and the components are mixed by rotating the screw, which is installed inside the drum. Thanks to this design, the concrete mixer copes with the preparation of not only liquid but also viscous solutions. Due to the constant rotation of the auger, the concrete mixer produces a homogeneous plastic mixture. Use such devices for large construction work, when it is necessary to obtain a large volume of liquid mixture. To buy such a device in order to fill the garden paths in the country, there is no point. Since this purchase is expensive and will not justify the money spent.

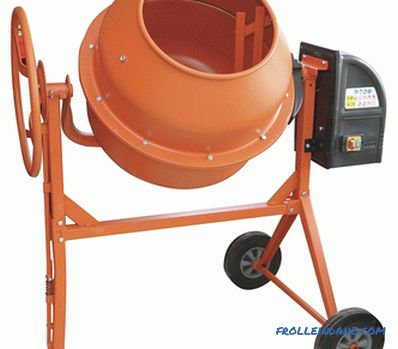

The principle of operation of gravity concrete mixers

If you are interested in which concrete mixer is better for the house, then you should pay attention to the device gravitational type of action. His work is based on the rotation of the drum itself, the blades that are inside are not moving. With the help of gravity concrete mixers, you can carry out repair and construction work in the house without the involvement of the construction team and the rental of professional equipment. Using a small device, you can independently make concrete and concrete mixtures of different plasticity in the right amount.

For performing professional construction work, it is better to use a forced-type concrete mixer. For homework it is better to buy a gravity-type device.

Which gravitational-type concrete mixers are better than crowned or gear-driven

When choosing which concrete mixer is better to buy among gravity-type devices, note that they can be two types: gear and crown.

Between themselves, these two types differ in several points:

- in cost;

- principle of operation;

- reliability and the duration of uninterrupted work;

- the possibility of repair and its cost.

Features of gearboxes

A concrete gearbox in the gearbox type is equipped with a separate gearbox in a closed housing, which is reliably protected from sand, cement or crushed stone. These units are more reliable and create less noise. However, they also require more careful operation and compliance with its conditions. If the gearbox still fails, then it is quite difficult to repair it. Independently, this process should not be taken. Repair of such a device is almost equal to the cost of a new device.

Features of coronary devices

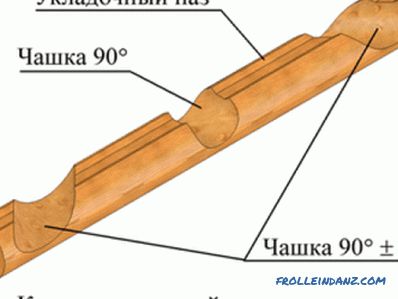

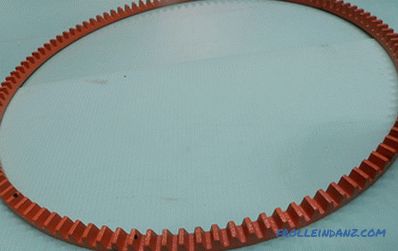

Coronary type concrete mixers are distinguished by an open mechanism, since the serrated vyshtampovka is mounted around the circumference of the concrete mixer drum. It is exposed to building mixtures, wear during operation, but it is not whimsical in work and maintenance. To fix the coronary mechanism is much easier.

Coronary devices are the most popular. They have earned their popularity due to the simple and clear design, which is easy to repair. Despite the fact that the gear devices are more reliable and durable in operation, they are expensive to repair and it is difficult to find a master who can do it. For coronals, you can pick up parts in specialized stores or order in online stores, and you can fix them yourself.

Which crown of the concrete mixer is more reliable

If you make a rating of concrete mixers for reliability, then, first, you need to pay attention to the material from which the crown is made. That he is responsible for the life of the mixer.

Pig-iron

Crown of cast iron is equipped with most concrete mixers of the average price category. The cast-iron crown is easy to manufacture: the cast-iron melt is poured into the mold; after solidification, the workpiece requires minimal processing. The inexpensive cost of the material and the simple method of manufacturing parts form the relatively low cost of the finished crown and drive gear. This is the main plus cast iron product.

There are several minuses at once:

- Cast iron is a brittle material, under mechanical action, the part may break;

- When reused, teeth will wear out;

- During operation, the heavy cast-iron crown makes a lot of noise.

Comparing the pros and cons, we can conclude that the concrete mixer with a cast-iron rim should be bought for non-systematic use with low and medium loads.

Steel

Steel is a very durable and reliable material that does not wear out as quickly as cast iron and does not burst when it falls or hits. By the way, in the process of work, the steel crown is much less noisy. However, it is worth an order of magnitude more expensive than cast iron. This is due to the process of manufacturing parts. First, the hot metal composition is poured into a mold and cooled. After extraction bring on the special equipment (grind and grind). In addition, the steel is subjected to hardening. All these processes increase the cost of detail, but at the same time contribute to its strength and reliability.

It is advisable to buy a device with a steel crown for daily hours of construction work, performed both outdoors and indoors.

Plastic

A plastic crown is the cheapest listed. It does not require large financial and production costs in the manufacture. One more plus of a plastic wreath is a silent work and its lightweight. The disadvantages include fast wear of teeth, which are erased from friction with the gear.

It is possible to buy a device of this type for carrying out small work at home. But in this case, you are not protected from the need for a quick replacement of the crown.

Polyamide

Polyamide is a modern durable and lightweight material that was used in the manufacture of concrete mixers not so long ago. It is not inferior to steel in strength, and plastic - in lightness. In addition, the material is resistant to high temperatures. Therefore, it is able to withstand heavy loads in the hot summer period, without being deformed or washed. Synthetic material is also resistant to the effects of natural factors - it does not rust from water, does not react to the effects of many abrasive products. Among the advantages of polyamide crown: strength; durability; ease; resistance to heat; resistance to electrical breakdown; collapsible ring design, simplifying disassembly and repair; quiet work.

Concrete mixers equipped with this type of crown are perfect for daily long-term work, both inside and outside the room.

Any crown, be it made of plastic or steel, is a toothed ring fixed around the drum. It sets the drum in motion by means of a gear that transmits motion from the engine. In the process of frequent operation, the teeth of the crown are erased together with the teeth of the gear under the action of friction and vibration. However, after wear, these parts can be replaced.

Also the wear of parts is influenced by the following factors:

- Ambient temperature;

- Water leaks into the drive mechanism during a rain;

- Sand, water or finished change into an unprotected mechanism;

- Incorrect assembly of the device;

- Shocks, mechanical damage, falling of a filled device.

Rating of the best concrete mixers according to user reviews

Next, we present to your attention the rating of concrete mixers for reliability based on user feedback.

Zitrek B1510 FK 024-1002 concrete mixer

+ Pros Zitrek B1510 FK 024-1002

- Fast uniform mixing;

- Powerful model;

- Really designed for making heavy mixture;

- Easy transportation after purchase.

- Cons Zitrek B1510 FK 024-1002

- When assembling, there are problems with the size of bolt holes, many customers expand them themselves;

- Noise during operation;

- Requires mandatory cleaning after use.

Results: ZITrek B1510 has a drum volume of 155 liters, at the output it gives out a concrete mix of 110 liters for 2 minutes. The drum is equipped with a cast-iron rim, rotated by a powerful engine of 1000 watts. Zitrek V1510 is designed to work on a small construction site or at home, suitable for mixing heavy concrete mixes.

Concrete mixer Lebedyan SBR-132A.5 95446

+ Pros Lebedyan SBR-132A. 5 95446

- Robust case and drum;

- Reliable blades;

- Withstand overloads (buyers loaded the drum instead of the recommended weight of 64 liters to 100 liters) .

- Minuses Lebedyan SBR-132A. 5 95446

- The drive shaft bearing is not secure (contaminated during operation, needs to be cleaned);

- The engine cover is heated during operation, the fans do not have time to cool it;

- During operation, the starter breaks down (the part is easily repaired, you can buy it for replacement).

Results: The concrete mixer is equipped with a cast-iron rim, kneads 64 liters of concrete and concrete solution in 2 minutes, it is possible to add a concrete fraction not larger than 4 cm. A special feature of the model is the possibility of partial extracting the mixture as needed due to the fixed tilt of the drum.

Concrete mixer Limex 165 LS 024 0240000

+ Pros LIMEX 165 LS 024-1008

- Large drum volume;

- It is convenient to extract the resulting solution in the right amount thanks to the latches ;

- It is convenient to move around the site at the expense of the wheels and a special handle.

- Disadvantages of LIMEX 165 LS 024-1008

- Does not withstand overload, if instead of the specified norm overload the device, the bearing breaks;

- The engine cover is heated;

- The starter button fails for some customers.

Results: The model was made in Europe, intended for the production of mortars and concrete mixes up to 110 liters. for one batch, equipped with a cast-iron crown. Differs in the convenient dosed way of supply of ready mix at the expense of a clamp. It can be transported around the construction site due to strong wheels and a comfortable handle.

Zitrek B 1308 FK 024-1000 concrete mixer

+ Pros ZITREK B 1308 FK 024-1000

- The design is really strong;

- Easy to transport and assemble;

- Not much noise.

- Cons ZITREK B 1308 FK 024-1000

- Those who assembled the model themselves for the first time had difficulties in assembling.

Results: The device is characterized by a reinforced, impact-resistant casing, equipped with a cast-iron rim, suitable for the manufacture of various concrete mixtures under home repair work or a small construction site. Kneads 80 l of solution in 2 minutes. The model moves around the site at the expense of wheels and a comfortable handle.

Concrete mixer Lebedyan SBR-132N / 220

+ Pros Lebedyan SBR-132N / 220

- Practically silent model;

- Quickly mixes a good quality solution;

- No open parts

- The drum turns around itself, due to which you can unload the mixture, deploy and load components without moving the concrete mixer (this feature is appreciated by those who have to work in cramped spaces);

- Simple assembly

- Minuses Lebedyan SBR-132 / 220

- No retainer for different degrees of inclination of the drum;

- Heated engine casing.

Results: The model is positioned as a high-speed one, producing up to 64 liters of concrete or concrete at a time. The device is equipped with wheels, it is easy to move around the construction site, and it is securely fixed in the workplace at the expense of a special handle. The design is reinforced by bolting.