Designers are very widely used method in which the combination of metal parts with wood. It touched the stairs. To make the construction durable, a metal frame is made, beauty and aesthetics are achieved by decorating surfaces with wooden elements. To answer the question of how to sheathe a metal ladder with wood, it is necessary to study the properties of the materials used for finishing, their technical characteristics. It is necessary to understand why metal and wood have the best combination, how harmony is achieved.

The metal frame of the stairs is very reliable and durable, and the wooden paneling adds aesthetic function.

Before sheathing a metal ladder, you must first select the appropriate design. There are several ways that answer the question: how to sheathe a metal ladder? You can decorate the frame of the staircase with a tree in different ways. You can make a staircase with steps, decorate the railings, decorated with wood.

Nuances of universal constructions

Natural wood has always created comfort and coziness in the house. It is safe to say that wood harmoniously combines with any interior, however, the frame of the stairs made of wood does not have great strength, it is short-lived. The use of a metal frame of a ladder as a supporting structure will be much stronger and more durable. Such a ladder is able to withstand a lot of pressure, it can have a variety of forms.

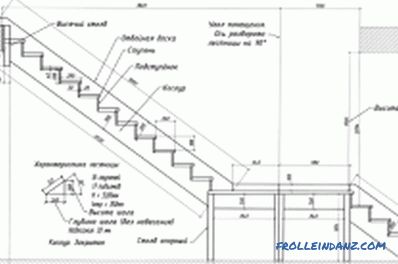

The layout of the metal ladder.

Stairs made of metal look very impressive, but if they do not have plating, they look unaesthetic. Moreover, the trim helps to reduce injuries in residential buildings.

With a more thorough acquaintance and study of facing materials, the conclusion is clear: in order to cover the metal frame, you need to use good wood.

The frame of the staircase is made mainly of light metals with high strength properties. To sheathe tread, hardwood is used. Other parts that wear much less are lined with low-cost and less hard wood.

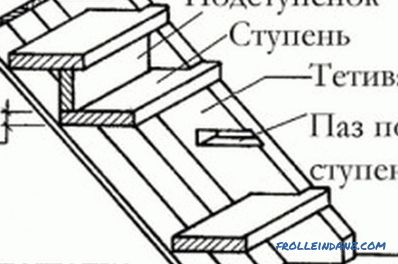

Ladder trim is made partial when the steel frame does not close completely. In most cases, make a full trim. The metal base, on which the wooden steps are held, is mounted on special bowstrings.

What material to choose for plating?

To emphasize the natural beauty, choose an array of oak. Such a tree will be an excellent sound insulator, the stairs will become more attractive and original.

Different types of wood and the developed design entail certain monetary investments. A project can be very expensive, but the cost does not always affect the result.

Scheme of metal staircase lining with wood.

The most demanded sorts of tree species are:

- Oak. Very durable, can serve for a long time. It has a large range of colors. Over time, it begins to darken. This makes it more attractive and luxurious.

- Beech. Elegant and sophisticated wood. It has a high density, very durable wood.

- Hornbeam. After a long drying, its hardness exceeds that of oak. This wood is also called white beech. Such a tree can be etched, fairly easy to handle.

- Ash. Characteristics of the tree are similar to the parameters of oak. It has high strength and wear resistance.

- Tick. Differs in the high durability, beautiful color shades.

- Coniferous trees are used when sheathing the risers, staircase fence parts, that is, in places where high strength and wear resistance are not needed. Such wood includes pine, cedar, etc.

I must say that the wood must necessarily have an excellent drying. Humidity level should not exceed 12%. If this figure is higher, the tree can "lead." Wood should not be cracked. Each wooden element is necessarily impregnated with an antiseptic to prevent the process of decay.

You will need the following tool to work:

- screwdriver;

- screws;

- rubber hammer;

- joiner's tools designed for cutting threads on wooden surfaces;

- planer;

- level;

- ruler;

- pencil;

- studs to fasten balusters .

Technology of performance of works

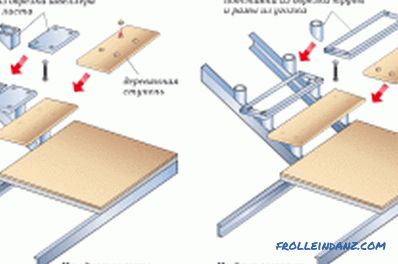

Scheme of the full covering of the metal frame.

To make a metal staircase paneling, it is required to know certain rules and procedure for the production of facing works. First you need to determine:

- ladder system;

- wood species;

- design;

- railing material.

Then it is necessary to measure the frame at the attachment points of the steps, determine the dimensions of the risers.In some cases, they may differ slightly from the size of the frame made. According to the measurements made, a sheet of plywood is taken, a substrate is cut out, which is placed under the treads. With the help of plywood eliminates a small slope of the metal frame. Then made parts steps. To make it easier to mount the risers, the masters advise treads to be made slightly wider than the metal frame.

Plywood backing is held together with mounting glue. Pre-set the treads, fastening them on both sides, then screw the risers to the details of the frame. The heads of the screws must be hidden, they are covered with mastic or covered with special furniture plugs.

The process of finishing the stairs with wood.

In the next step, ladder fence is installed. It is attached to the treads or, if the width permits, to the end of the march.

The next step is to mount the metal frame and the wooden parts. For this purpose, a screwdriver is used. Markup is preliminarily made on the parts where the fixing will be performed. To do this, you need to put a part on a specific section of a metal ladder, make marks with an ordinary soft pencil. Each step must be equal to the specific details of the stairs.

Fastening begins with the steps. They need to be fixed so that they slightly come forward, approximately 1 cm. It will look very beautiful, will create maximum security. Work with the screwdriver should start at the top, slowly moving down. When the last step is screwed, you need to check the structure for strength. How smoothly installed steps, determine the plumb.

Practical recommendations

Stairs with wooden elements that protrude slightly beyond the metal surface look very beautiful.

It is desirable to use hard wood for linings.

In order to avoid chipping of the skin, you need to make chamfers over the entire area of the wooden panels, all corners must have a round shape.

Balusters should be installed at the edges of steps along the entire length of the stairs. When the level shows absolute verticality, the balusters are fixed with special studs. Then fasten the railing.

When stair designs are made, it is possible to combine metal and wood. For metal parts, even scrap metal will do. It will only be necessary to choose the most suitable option so that it fully meets the functional, aesthetic and financial possibilities.

Didn't find the answer in the article? More information on the topic:

-

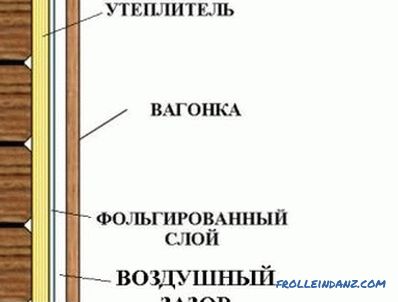

Upholstery clapboard with your own hands

Instructions on how to do the upholstery clapboard at home or giving: do the job yourself The list of necessary tools, stages, features of fastening material.