Earlier, the arrangement of a heated floor was a pleasure not cheap, and only in the bath he could pay for himself. As for our days, now the situation is quite different. This technology has spread so widely that now many can afford it. Distribution of the heating circuit over the floor will allow to maintain a uniform and stable temperature throughout the living space. However, it is not always easy to implement. For example, what can be done in a wooden floor? Complicating the problem may be that the finishing floor material is linoleum. Is it possible to combine all this? A careful study of this issue, you can not only make sure that it is real, but also to test your strength and independently make a warm floor under the linoleum on the wooden floor. We suggest you to study this topic in depth.

Features of a warm wooden floor

Even in a wooden house with wooden floors, floor heating

Even in a wooden house with wooden floors, floor heating

The main principle of a heated floor is to transfer thermal energy through the floor surface to the room. This development is successfully used in the case of a concrete floor. The material has a high thermal conductivity. Moreover, it accumulates heat and creates a comfortable feeling in the legs.

In this case, the question arises: if this system is so efficient, why not take and replace wooden floors with concrete ones, or at least pour concrete screed over a wooden floor? It may seem that this is the right decision, however, there are some nuances here, although an effective system has been developed for filling the wooden floor with a tie. Even with a minimal layer of the screed, a minimum of 70 mm thickness is required for a water-heated floor, a constant pressure of about 300 kg will apply to a 1 m 2 wooden base. And given that the floors are not always smooth, you may need a larger layer to align them.

From this, it is reasonable to assume that it is risky and unreliable to hide wooden floors under concrete. The tree collapses with time. And even if this system of 30-40 years will not fail, your children can reap the bitter fruit, it is at best. Considering these factors, we completely exclude this process, all the more so since a technology has been developed that allows laying the heating circuit on a wooden floor. Plus, it has a number of positive aspects:

- the minimum weight of the heating "cake";

- thermal energy goes a little way before users feel it;

- the ability to combine with linoleum and other carpet materials;

- the installation time is significantly reduced;

- after installation, you can immediately put into operation;

- wet works are completely excluded;

- load per 1 m 2 up to 30 kg, this is 10 times lighter than the concrete system;

- additional load on the wooden structure is also excluded About overlappings, especially in cases when wooden beams are such;

- besides the weight, the size of the cake also decreases, which excludes the likelihood of a strong decrease in the height of the room.

However, for the sake of objectivity, it is worth noting that the wooden heating floor will not be able to act as the main heating. This material has a low thermal conductivity. Therefore, to a greater extent, such a system is an excellent addition to the main heating radiator system, which will help to maintain a pleasant microclimate.

In some cases, pouring a wooden floor can destroy the foundation

In some cases, pouring a wooden floor can destroy the foundation

Besides, you should also consider the floor coating, in this case linoleum. It is important to approach the implementation of this issue with a cool head, as there are some important points that will be discussed further.

Choosing linoleum for underfloor heating

Choosing linoleum for underfloor heating important action

Choosing linoleum for underfloor heating important action

In the question of choosing linoleum for a warm floor should be approached slowly. Now we look at the types of linoleum and find out how they react to the warm floor, or rather, whether they can be combined with heating.

Types of linoleum

Linoleum is divided into five large groups that differ in the binder:

- rubber, also known as relin;

- colloxylin (nitrocellulose);

- glyphthalic (alkyd);

- polyvinyl chloride (abbreviated name PVC);

- natural.

Let's compare PVC and natural linoleum:

| Specifications | PVC | Natural |

| Technical side | PVC linoleum today is made with different sub-bases:

| Natural linoleum is of two types:

Natural materials are mainly used as the basis. By its chemical composition, this material is closest to the original. It uses the following components:

The jute fabric serves as a base. |

| Strengths and weaknesses | When the temperature rises to 2% PVC, linoleum shrinks, except for foam-based material. It has a specific smell, which disappears over time. | Natural linoleum does not contribute to the spread of fire. It is easy to clean it from dust and other dirt. After installation retains its size throughout the entire operational time. The presence of flaxseed oil eliminates the accumulation of electrostatic discharge, in addition, it has a bactericidal effect. After a while, it does not fade and does not change its structure. The material is resistant to ethyl alcohol, fat and non-concentrated acids. However, under the influence of alkali is destroyed in case of prolonged exposure. This is explained by the fact that it contains limestone powder, which reacts with alkali. |

Why should we go into it? Knowledge of the composition of the material will make the right conclusion as to whether linoleum can be laid on a warm floor. So, according to the research, it is multi-layered PVC linoleum that is most adapted to floor heating. Why?

Fiberglass is used as a base, which is processed from the front side with a special PVC paste (impregnation). Next, apply a second layer of PVC. It contains other components. When printing and engraving can be used up to six colors. The final layer is a fixing transparent PVC layer with a thickness of up to 0.15 mm. As for the basis of fiberglass, it is protected by a substrate (it can be polyester, fabric, jute or foamed PVC). Just foam PVC substrate is considered the most adapted to the temperature expansion. Such a multi-layer structure completely eliminates the possibility of deformation of the material when it is heated. However, with regard to environmental friendliness, then by this indicator it is significantly inferior to natural.

Linoleum should be suitable for floor heating

Linoleum should be suitable for floor heating

Consider the features of other types of linoleum:

| View | Specifications |

| Colloxylin (nitrocellulose) | Elastic and moisture resistant material. It is a thin coating. Its structure is very sensitive to temperature changes. As a result, it is not recommended for use with heated floors. |

| Glyphthalic (alkyd ) | This type of linoleum is close to natural in its composition. It is based on glyptal resin, which is made from glycerin, vegetable oil and phthalic anhydride. It is worth noting that these components undergo oxidation. This material can be combined with warm electric and water floor heating systems. |

| Relin (rubber ) | This type of linoleum is mainly used in industrial premises. However, it contains hazardous volatile substances that, when the temperature rises, are extremely dangerous for the human body. The conclusion is obvious: the use of Relin in combination with floor heating is unacceptable. |

that all this information is presented for those who want to figure everything out on their own. Those who do not attach importance to this, the manufacturer simplifies the selection process. How? On the label to the packaging put a special sign / marking, the presence of which indicates the possibility to lay the linoleum on the warm floor.

Near the special marking should be an indication regarding the temperature regime.For example, for marmoleum or natural linoleum there are limitations up to + 27 ° С. For PVC linoleum limit is up to + 29 ° C. Considering this, when installing a heated floor, a mandatory requirement is the installation of a thermostat.

Temperature condition

Marking of linoleum

Marking of linoleum

Special attention should be paid namely, the temperature regime during the operation of a heated floor under linoleum. This material requires uniform and smooth heating, unlike laminate. Accordingly, the power of the heating circuit should not exceed 150 W / m 2 . With such power, the surface will warm up to a maximum of + 28 ° C.

If you ignore this requirement and put a heating circuit of greater power, then with intensive heating there is a risk of the following phenomena:

- color change;

- the base may expand and peel off ;

- large quantities of phenol will begin to be released - a harmful and dangerous substance;

- the material will become vulnerable to rupture due to softness.

If this requirement is met, it may seem that the floor is not warm enough. It is important to realize that the surface of the linoleum should not be too cold or hot. If there is not enough heat, then radiator heating should be carried out, and floor heating should be used as an auxiliary one. For example, in the period when there is no severe frost. Using floor heating, you can save money on energy, which will positively affect the payments for electricity / gas.

Choosing a heating circuit: water or electric

There are several types of underfloor heating:

- water;

- electric (cable);

- electric infrared.

Water heating

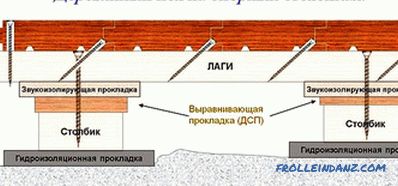

Underfloor heating on a wooden base

Underfloor heating on a wooden base

This refers to a system of pipes laid in a specific sequence. Thanks to the pump, the coolant circulates throughout the entire system. The combination of such heating with linoleum is complicated if you use a centralized system. Why? Although there are working diagrams for connecting a heated floor to a central heating system, there is always a risk of a temperature sensor failure. Much easier if you have an individual heating system that will allow you to provide the necessary temperature control.

Among other things, with poor-quality installation there is a risk of leakage, which negatively affects the concrete base, and the more so on a wooden floor. However, despite this, a system for installing water heating on a wooden floor was developed. In this case, special metal plates or flooring systems are used, made on the basis of expanded polystyrene and having corresponding grooves for laying pipes.

Water heating circuit laid in guides

Water heating circuit laid in guides

Ready-made modular chipboard with channels can also be used . Known and rack system, where the channels for the installation of pipes are formed independently. In this case, the channels are formed not by the milling method, but by packing the rails. As the rails can be used edged board or moisture-resistant plywood. The thickness of the slats may be in the range of 21-28 mm.

As regards the width of the channel, it must be sufficient so that the pipe does not deform in the process of moving the wood. At the same time, the distance should not be too free in order to avoid the heating contour bending with increasing temperature.

Video: Features of installing a water floor on a wooden floor

In this video you can see the principle of laying pipes in a wooden base. However, in this case laminate is mounted on top:

Electric heating

Electric floor heating under linoleum

Electric floor heating under linoleum

As for electric heating, there is more freedom of action. Today there are several technologies that are successfully used in combination with linoleum and wooden flooring:

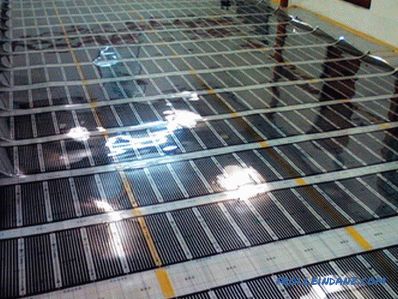

- infrared film with carbon heating elements;

- Unimat core mats;

- resistors heating mats;

- self-regulating heating cable;

- resist heating cable.

Video: which electric floor heating is better than

When using electric heating it is important to follow several rules:

- the heating circuit should not to have direct contact with wood and heat-insulating layer;

- if it is necessary to cross a wooden log, then it is necessary to cut it and the cable is insulated with foil or aluminum tape.

There is an opinion that film infrared heating is the best for organizing floor heating.This is true, but with a few nuances:

- the heated area of the room should not exceed 30 m 2 ;

- a prerequisite is to use a temperature sensor and thermostat for maintain an acceptable temperature under linoleum up to + 27 ° C.

Preparation of a wooden floor

Preparation of a wooden floor for installation of a heated floor

Preparation of a wooden floor for installation of a heated floor

Regardless of the selected floor heating system, the key step of the installation work is the evaluation and preparation of the base floor. The first is a visual assessment of the sex. For example, are there gaps between the boards, are there rotten boards. To determine the quality of the beams, it is necessary to raise a small portion of the floor. Considering that you plan to do a warm floor, the effort expended at this stage fully justifies itself.

If the floor has gaps, then they should be filled. Otherwise, there will be large heat losses and increased power consumption. You should also replace those areas that are prone to rot or mold.

If rotten beams are found, they must be replaced. If part of the beam is in good condition, it is possible to make partial cutting out with its subsequent replacement.

If necessary, the floor should be carefully polished to eliminate irregularities

If necessary, the floor should be carefully polished to eliminate irregularities

If the floor is relatively uneven , it is necessary to lay special pads under the supports, reinforce them with metal corners, and also provide additional fixation. If rotten boards / beams have been replaced, then to prevent such a phenomenon, floors should be treated with a deep penetration antiseptic.

A vapor barrier should always be placed between the support beams and the finished floor. The heat insulator is placed on top. It can be mineral wool, foam plastic, polystyrene foam, etc. The thickness of the insulation should be about 200 mm.

Among other things, there should be a space of up to 100 mm between the finishing floor and the thermal insulation. This will allow to organize the ventilation system in the subfloor subfloor. Considering this, small gaps should be left around the perimeter of the wall.

Installation of underfloor heating

In this section, we will discuss with you a few step by step instructions on how to install a warm electric / water floor on a wooden floor. As an electrical, we consider the technology of laying infrared film.

Installation of a warm water floor

Installation of a water heated floor with the manufacture of special channels

Installation of a water heated floor with the manufacture of special channels

The principle of operation and installation of such a system on a wooden floor can be found in the section "Water heating" in the prepared video. Although it shows the technology of installation under the laminate, the principle of installation work is identical.

In general, the technology is as follows. A special plate unfolds over the surface of the wooden floor. If you decide to use printed rails, then you should form the pipe laying step yourself. In the formed channels fit the heating circuit, which is connected to the distribution manifold. The pipe in the channels is placed in the foil.

After the installation is completed, the plywood is laid on top. After that, foamed polyethylene and linoleum itself creeps.

Installation of an electric infrared floor

We suggest that you familiarize yourself in all details with the technology of installing IR heating for linoleum on a wooden floor. Following all instructions, you can figure everything out, as well as complete the work yourself. Plus, it will be useful to get acquainted with the prepared video.

Precautions when installing electrical heating

It is important to follow safety precautions when working with electric heating

It is important to follow safety precautions when working with electric heating

It is important to remember that wood and electricity need to be isolated from each other. Therefore, when carrying out work, be sure to take the following measures:

- exclude direct contact of the heating cable with combustible materials;

- during installation observe safety precautions;

- do not stack heating elements under furniture and other large objects;

- when installing, be careful with cable insulation;

- the power of heating elements for a wooden floor should not exceed 80 W / m 2 ;

- Be sure to set the automatic thermostat.

Thermal insulation for infrared heating

Under an infrared heat-insulated floor, a heater

Under an infrared heat-insulated floor, a heater

There are different opinions regarding the question of whether a heater is needed for an electric floor heating. However, regardless of the quality of the base, the lack of insulation leads to 30% heat loss. Moreover, if you use a heat insulator, the heat loss is reduced to 9%. So, the conclusion is obvious - it is better to use a heat-insulating layer for electric heating.

When choosing a heater, you should pay attention to the following criteria:

- Thickness.

- Thermostability.

- Ability to reflect heat.

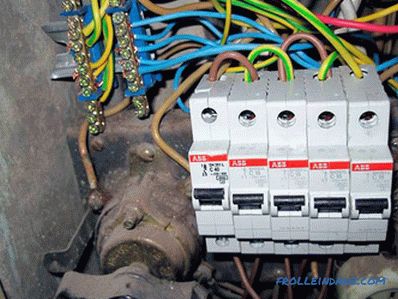

Checking the electrical wiring

Before starting work, always check the wiring

Before starting work, always check the wiring

Before introducing a warm electric floor, determine the quality of the existing wiring. Considering future high loads, it must be in good condition. Please note that it is prohibited to connect electrical heating to the outlet.

If, in the course of analyzing an existing transaction, you concluded that it is not able to cope with the intended load, then it should be completely replaced. Alternatively, you can draw a separate line from the panel, which will be used exclusively for floor heating. In this case, an RCD is mounted on the control panel.

Required material for work

The complete IR floor kit contains all the necessary

The complete IR floor kit contains all the necessary

So, for the work it is necessary to prepare the following materials and tools:

- temperature sensor;

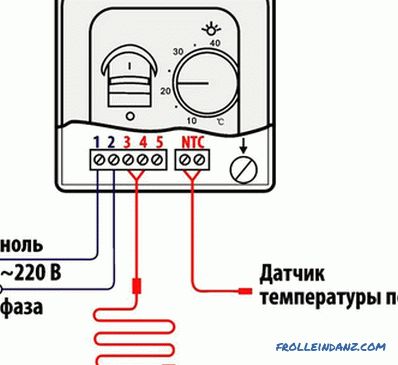

- thermostat;

- foil insulation;

- infrared film film;

- all components for IR film (usually provided in one package);

- ordinary and foil adhesive tape;

- 200 μm plastic film for the entire area of the room;

- plywood or other sheet material;

- linoleum

- acute assembling / stationery knife;

- pliers

- driver set

- tape

- marker or pencil.

Installation location of the thermostat and temperature sensor

Pre-determined place for installation of the thermostat and temperature sensor

Pre-determined place for installation of the thermostat and temperature sensor

Before starting work, it is necessary to determine the place where the thermostat will be installed. The ideal place is the wall. The recommended height from the floor is 500 mm. The selected location should be available for visual inspection and possible adjustment.

The location of the temperature sensor is also determined. It should be laid at a distance of about 500 mm from the edge of the film and in the center of its width. Some experts practice its installation in the coldest point of the room, however, this is not always possible. You can get acquainted with the working diagrams of the infrared floor heating.

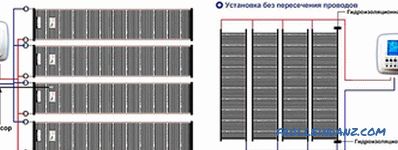

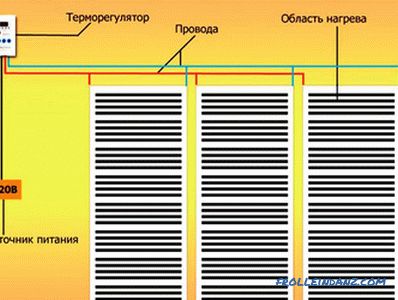

Circuits: connecting infrared film

Two connection methods

Two connection methods

Conventional connection scheme of the infrared floor

Conventional connection scheme of the infrared floor

Connection diagram of the infrared floor through the thermostat

Connection diagram of the infrared floor through the thermostat

Connection diagram of the thermostat with the system underfloor heating

Connection diagram of the thermostat with the system underfloor heating

Installation work

The entire work process consists of the following steps, which are presented in the table:

| Work steps | Description of the technological process |

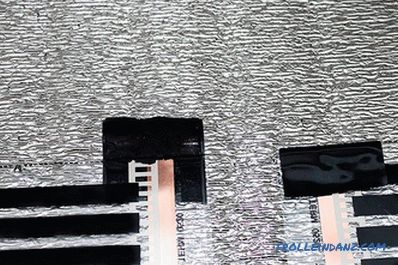

| Step # 1 | Before we had already done preparatory work on wooden floor. Therefore, the next step is to cover the entire area with a heat-reflecting foil substrate. Laying the heat-reflecting layer is recommended with a small allowance for the walls. After laying the infrared heating and plywood, it is then simply trimmed. Thus there will be a small gap between the wall and the plywood. It is important to ensure that the strips of material fit the joint to the joint. The heat-reflecting film is connected to each other with foil tape. |

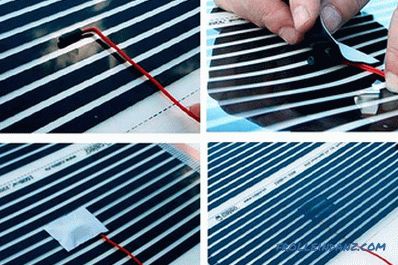

| Step # 2 | At this stage, it is time to lay out the infrared film. At the same time, it is important to control that the side with the copper strip looks at the heat reflector. Between the IR film nowhere should not intersect. On each strip there are conductive tires. Between them there should be a distance of about 50 mm. |

| Step # 3 | It should be noted that the IR film should be laid out according to the prepared project. In some places it will be necessary to lay small pieces. To make an incision of the film, specially designated for this place are used (the cutting line is located with an interval of 250-300 mm). For cutting you can use ordinary scissors. |

| Step №4 | Places where the tire was cut should be covered with insulation. This applies to places that will not be used. Usually insulation comes with the kit. Using it is important to achieve complete sealing of the tire incision. |

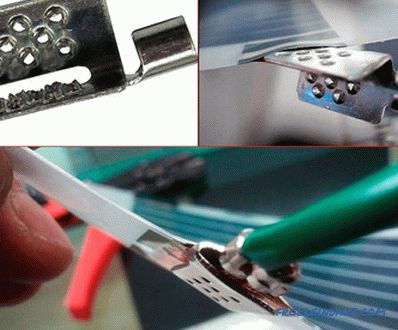

| Step No. 5 | Now it is necessary to connect the terminal. It should be brought in a small bundle on the film.It is located in the strip busbar. The terminal has two petals. One is placed inside the film, and the other outside. After the clamp is securely clamped with pliers. According to the chosen wiring diagram, conduct a similar operation in all places where the wire will be connected. |

| Step №6 | It is time to connect the cable to the already fixed terminals. So, you need to clean the end of the wire from the insulation and lead it into a special connector on the terminal. For good contact, the terminal should also be securely clamped with pliers. If parallel connection is chosen, then there will be two wires in one terminal. |

| Step # 7 | After connecting all the wires, insulation is a must. For this purpose, bitumen insulation is used. A small piece of insulation is glued to the top and bottom of the contact. This operation must be performed on all terminals. |

| Step No. 8 | Now the temperature sensor is fixed. It should be glued to the center of the central black strip with insulation. Pay attention to the fact that a special window should be cut out for the sensor and this will allow to hide the sensor. Due to this, the film coating will be smooth. Similarly, the wires are hidden. For them, you should carefully cut out small grooves. |

| Step No. 9 | When all the wires are fixed, the infrared film must be securely connected to each other with tape. All places where wires are laid, also sealed with tape. |

| Step # 10 | Now it is necessary to connect the temperature sensor to the thermostat. To do this, use the instructions from the manufacturer. Before you make the linoleum flooring, it is recommended to test the entire floor heating system. If everything works properly, then you can proceed to the final stage. |

Linoleum flooring

Linoleum flooring on a warm floor

Linoleum flooring on a warm floor

The final step is laying linoleum. In order not to damage the electrical part of the heated floor, plywood or similar sheet material is pre-laid. Previously, plywood is packed with plastic film, which must be glued together with tape. When installing plywood, all fasteners should fall on the sections of the IR film, where there are no heating elements and connection cables.

Before installing the linoleum, the substrate

Before installing the linoleum, the substrate

is always spread out. After that, you need to lay out the linoleum and leave it for one day . The material will settle, and it can be cut to size. Will you glue it or leave it to dry, you decide. Everyone chooses the technology of installation of linoleum, which he knows. However, it is important to take into account one technological nuance: if you decide to glue it, then note that when heated, the glue may begin to peel off. Therefore, it is important to choose the right glue, but in this case the substrate does not creep between the linoleum and plywood. In most cases, linoleum is not glued.

So, we have discussed with you how to make warm heating on a wooden floor and under linoleum. We invite you to leave comments on this article, what do you think about this.

Video: Features of mounting an infrared floor