The construction of the frame structure occurs quickly enough, and the technology of its construction is simple. Therefore, to build your own small frame house 6x6 with your own hands is quite able to non-professional. The house, built on frame technology, is durable and comfortable, it is possible year-round living. At the same time, the cost of building a frame house will be several times less than the cost of a stone building.

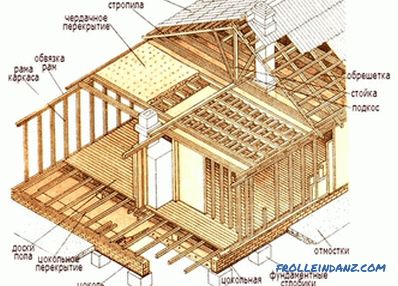

Schematic of the frame house.

Principles of building a house on a frame basis

When building a frame house, the main costs are related to the construction of the foundation. The foundation is more often used as a foundation and pile foundation. The frame house of 6x6 m has a small weight, which does not create a significant load on the soil. This makes it possible to build a structure on the soil of any type. For the construction of the frame can be used both wood and other materials.

The technology used is that the carrier is first mounted, then it is covered with panels.

With this method of building construction, no shrinkage of the house is required, therefore, finishing work can be performed immediately. High thermal insulation properties of the building contribute to a significant reduction in the cost of its heating. It is quite possible to build a frame house 6x6 with your own hands in a short time (about 2 months).

Construction of the house

The work will require tools:

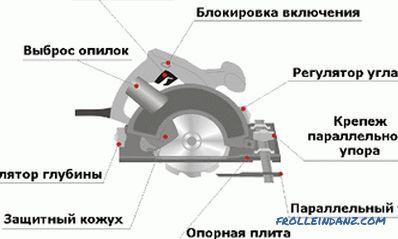

Tools for the construction of a frame house.

- construction level and tape measure;

- punch;

- Bulgarian;

- drill;

- hammer;

- nail puller;

- screwdrivers;

- ladder;

- scrap.

Materials:

- asbestos pipes (height 1.5 m);

- a beam treated with fire retardants and antiseptics (100x150x600 mm) 6 m long;

- timber 50x150 mm;

- boards;

- concrete;

- roofing material;

- anchor bolts;

- nails;

- pins;

- OSB plates;

- chipboard;

- insulating and waterproofing materials;

- plasterboard;

- siding;

- metal tile;

- communication.

When building a frame house with your own hands, you need to adhere to the following order:

Installing the walls of a frame house.

- To create a pillar foundation of a frame house in the soil with a step of 70 cm, holes for pipes (diameter 20 cm, depth 1 m) are made.

- The pipes are inserted into the wells, covered with earth and compacted well, then concrete is poured into each pipe.

- After the concrete dries out, a timber is laid on the foundation as the base of the frame, isolating it with roofing material. The position of the beam is controlled by the level, fixed bars with anchor bolts.

- A plank of the base floor is laid on the timber.

- On the floor with a step of 50 cm, lags are placed between which the insulation mats are placed.

- Carry out the bottom trim using grooves (50 cm step, 10 cm length) bars. The edges of the bars also connect with grooves.

- Install the pins for fastening the vertical posts, drilling holes for them in the slots. Then, bars are put on the pins (150x50 mm), starting with the installation of the corner posts.

- The vertical bars are successively tied with temporary stubs, the stands themselves are carefully fastened.

- After installing all vertical racks in a similar manner to the top, the bottom piping is performed, having the grooves identical. The upper trim is fixed with nails, the length of which is 10 cm more than the thickness of the trim bars.

- Temporary replacements are replaced by permanent ones, which, assuming part of the load, make the frame house durable.

Now the main frame of the house is built.

Finish work by erecting the roof and finishing the building:

- The ceiling beams (from a 150x50 mm bar) are attached to the frame, positioning them above the vertical posts and joining at the ends at an angle of 50 degrees. Rafters knock nails.

- The final construction is reinforced with an A-shaped horizontal board.

- Inside the house, 6x6 m will be equipped with partitioning beams supporting the boundaries of the interior.

- In 10 cm steps, ceiling girder boards are attached to the ceiling beams, which should protrude 20 cm behind the rafters.

- They install waterproofing, chipboard and install roofing material on the crate.

- The frame outside is sheathed with OSB, it is waterproofed and trimmed with siding.

- They lay communications, make waterproofing and screed the floor.

- Insulate the attic and install windows.

Now it is possible to equip a rainwater drainage device and carry out the internal arrangement of the frame house.

The use of metal profiles to create the frame

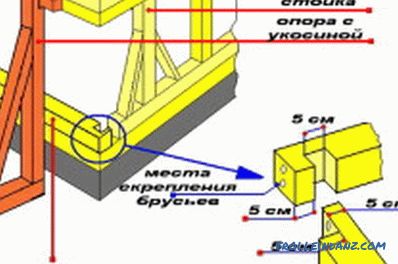

Scheme of assembly of the frame house 6x6.

A 6x6 m house can be built using LSTC. Such structures are galvanized steel profiles.Metal frame houses collected from them on the principle of the designer without the use of welding. Most building materials are non-flammable, and galvanized profiles are corrosion resistant. The strength of the steel frame allows you to make wide window and door openings and apply any facing materials. Weight 1 square. m of this house does not exceed 150 kg, so the building on the steel frame can be built on weak grounds. It is possible to purchase a finished building frame.

To build a house with your own hands, 6x6 m using a metal profile, you will need tools at the stage of building the frame and filling it:

- screwdriver;

- drill.

Materials:

- self-tapping screws;

- thermal insulation;

- OSB panels;

- drywall.

They work in the following order:

- After the foundation has been erected, a metal profile is prepared, cut into account with preliminary calculations and marked.

- According to the plan, a metal frame is assembled on the foundation using a screwdriver and screws for assembly.

- Fill the walls with insulating materials.

- Finish the construction of the final finishing of the roof and walls, laying of communications and the final interior decoration.

If it is decided to build a frame house with your own hands, then the size of 6x6 m will be optimal. Using a minimum of effort and building materials, you can quickly build a reliable, convenient and durable house. Such construction, adhering to the developed technology, it is quite possible to carry out independently. For successful work, you must follow the step-by-step instructions and carefully carry out all stages of construction.

Didn't find the answer in the article? More information on the topic: