A circular saw is easily made by hand at home. There are several methods for making a circular saw from a grinder, a circular saw, a drill and an electric motor. Such a machine can be manual or electric.

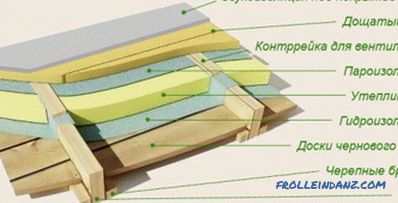

Diagram of the device for a circular saw.

Highlights

The circulation table is a stable structure, the frame of which is made of wood or metal. In a bed the cut for a saw is provided. Plexiglas, chipboard or iron sheet are used for its manufacture. The wire is attached to the last element. To gain access to the components of the machine will need to make a removable cover.

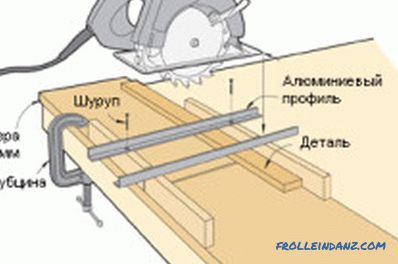

The bar is made of a corner fixed to the slab. This item may be sliding. In this case, the sides of the table cover should be parallel to each other. Sled made of steel or aluminum angle. If the last part of the circular saw is made of wood, then you get a large frame with a shorter service life.

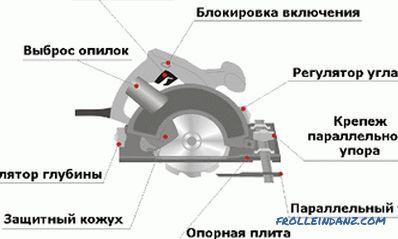

Barrel for circular saw.

To make a small unit, you need a round pipe with a diameter of 20 mm. On the crossbar set swing arm. The lower ends are fixed to the table with self-tapping screws. Along the cut, the fasteners are cut. To install the T-shaped lever, you need to cut the stick into 2 equal parts. Clamps are required for fixing them.

You can make a circular saw from the grinder. To do this, a circular saw is mounted on the last unit. The resulting tool is used for cutting. Installation work is recommended on the table top (bottom). For the nozzles of the main unit used machine for finishing thin boards.

The resulting tool is capable of sawing wood of the thickness for which the appliance is designed. For processing thick wood used a powerful electric motor. In this case, you need to make a pendulum frame. The frame is made of steel angle. One side must be in limbo. The height of the other side is adjusted by means of a screw mechanism. This design allows you to adjust the height of the discs.

The desktop circular saw is made by own hands according to a certain technology.

The difference between the stationary analogue and the desktop structure lies in the height of the bed.

If the tool will be used rarely, then you can make a light table saw. Otherwise, mount a more practical counterpart.

Step-by-step instruction on how to make a saw

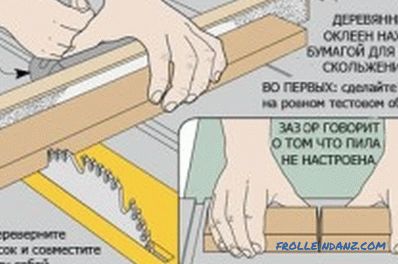

Circuit testing check circuit.

To make a table for a circular saw with your own hands, you need a galvanized sheet, a corner (80 mm) and a horizontal shelf.

To adjust the angle stop, use a corner whose length exceeds the table length by 400 mm. From the shelves on all sides cut off 2 strips (taking into account the length of the table). The ends must be bent down. In the lower shelves make holes. Put on the table emphasis, which is fixed with bolts. The limiter should be positioned between the circular saw blade.

The shaft is bought ready-made. Bearings are installed in 2 rows. It is necessary to provide special pins to protect the tool from sawdust and dust. The gear ratio of the unit depends on the engine speed and the rotational speed of the disc. The considered tool can be equipped with an asynchronous single-phase motor. The three-phase unit is used with oil-paper, paper and starting capacitors. Industrial motors require grounding and voltage over 600 V. The engine starts up to 3 seconds.

If a power unit with 3 phases and 1500 revolutions (power 2 kW) is used as a motor, then the frame is made of 30x30 mm shaped tube. The top cover is made of PCB with a thickness of 12 mm. It is attached to the metal frame using a similar shaped tube.

In this case, the lid rises (from the 1st side) and the shaft stands still. The lifting of the cover is regulated by a bolt. There is a nut and a large washer on the outside. Then the lid is lowered. The bolt is a reliable clamp. Cutting wood is made after a set of the desired engine speed.

It is necessary to work with a circular saw in goggles, at the same time norms and requirements of safety precautions are observed. In the room where the wood will be cut, there must be a first-aid kit with appropriate preparations, bandages, cotton wool, green paint and hydrogen peroxide. Similar safety rules must be observed when working at the factory equivalent.

Didn't find the answer in the article? More information on the topic:

-

How to choose the right face saw

How to choose a face saw? This tool requires high speed, accuracy of execution of specific operations, ease of execution of work.

-

Instructions: how to choose a miter saw

How to choose a miter saw correctly. General information about the tool. Characteristics of some models. What should pay particular attention when choosing a device.