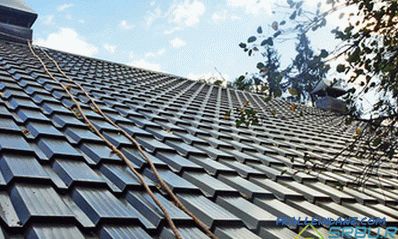

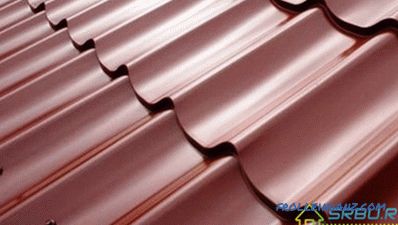

This material for the roof, light in both weight and installation, attracts developers with its stylish design, durability and affordable price. To help you navigate in its brands and manufacturers, we will consider all the main types of metal tiles, depending on the material used in the manufacture of base, profile geometry, and polymer coating.

Materials used for the manufacture of metal tiles

Steel sheet

It is galvanized steel that most often serves as the basis of metal tile. Its thickness can be from 0.45 to 0.55 (less often to 0.6) millimeters. The zinc coating protects the metal from corrosion. On top there are several reinforcing layers, including polymer. In this case, steel with applied zinc or aluzinc may be used. The second coating is more durable, but the cost of such a metal tile is much more expensive.

Aluminum sheet

This metal is good because it does not need to be protected from corrosion - it is absolutely not susceptible to it. However, an additional coating for aluminum tile is available - it increases the strength and life of the roof. And aluminum tile is very light. Here are just poor things in her palette of shades. And it costs significantly more than a roof made of other materials.

Copper sheet

This tile looks noble and elegant, especially with the time when a patina of greenish patina forms on it. Architectural monuments and old houses covered with a metal tile made of copper look beautiful. Patina is the best protection against adverse factors, so no additional polymeric coatings are needed. Such metal tile is expensive and is used extremely rarely.

Types of metal tile depending on the geometry of the profile and the depth of the insole

Surely, many have heard of such types of metal tile for the roof as Monterrey, Joker, Banga and Cascade. However, there are relatively new profiles that have a very interesting design and great quality. This, for example, brands such as Andalusia, Modern, Shanghai.

A metal tile with a Monterrey profile

This roof covering, which came to us from Finland, is extremely similar to clay tiles. Because of this, it has won the most fans. Tile Monterrey - light, aesthetic, simple to install, perfectly protected from natural disasters. The profile of this roof is smoothly rounded, which allows you to immediately recognize it, just by looking. After all, the appearance of various brands of this metal is very similar. The edge of the roof is decorated in the form of steps, which can be located both strictly symmetrical and asymmetrical.

- Advanced. . Check out what’s left or leave your feedback on Monterrey tile.

Metal tile with a profile of Cascade

This roof, slightly resembling the shape of a chocolate bar, attracts those who appreciate savings. Tile Cascade is distinguished by the severity of rectangular outlines, so it is very good to roof a complex shape. It turns out strict, accurate and proportional. In general, this is a classic style that will never go out of style and will always be relevant and with time.

- Advanced. . Check out what’s left or leave your feedback on Cascade metal tile.

Metal tile with Joker profile

Round ridge and plantar part, classic shapes - these are the differences of this coating. The "right" waves create the illusion of a ceramic tile roof. Those who appreciate traditions and classics will surely like the roof of this metal tile.

- Advanced. . Check out the quotes or leave your feedback on the Joker metal tile.

Metal tile with a profile of Bang

This roof is still quite young - it was started to be made recently. Her profile is different pretentious forms, and the external design shines with originality. Due to the structure of the profile and the increased wave height, a persistent three-dimensional image effect is observed. But the width of the metal is small, which, however, does not detract from its merits. This material is best used for the roofs of high houses - there it looks the most effective.

Metal tile with a profile of Andalusia

And again, a roof covering that is not yet quite popular is quite new for our country. In its manufacture uses a special European equipment. It makes it possible to fix the tile in a hidden way. And this is a big plus - even at the Monterrey tile, one of the most popular on the market, fasteners are made openly. And screws sometimes quite strongly striking. But "Andalusia" not only looks great, but also has high moisture resistance.After all, her sheets are connected tightly-tightly with special locks.

- Advanced. . Check out the quotes or leave your feedback on the Andalusian metal tile.

A metal tile with a Shanghai profile

And finally, a roof whose symmetrical pattern came to us from China. About it, the Russian developers learned the most later. Its complex high profile (66 millimeters) is symmetrical. Due to this, equipment for the manufacture of metal can be made and professional sheet.

There are other types of metal tile profile, but the ones listed above are the most common. Manufacturers are constantly working in this direction, replenishing their collections with new and new types of metal tile profiles.

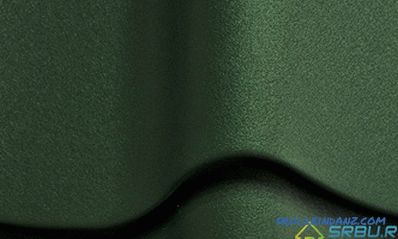

Types of polymeric coatings used to protect metal tiles

The type of protective layer largely determines how many years it is destined to serve as a metal tile roof. We note that more recently, a high-quality polymer film was applied to a metal sheet only abroad - after all, this process is rather complicated. However, now our manufacturers have learned to make excellent shingles with a durable polymer coating. Such products of Russian companies Grand Line, Metal Profile, Interprofile are highly valued.

There are many types of metal tile coatings for which different polymers are used. Some of them provide an opportunity to endure the frost and heat withstand, others save from burnout and ultraviolet radiation, others - plastic and durable. In addition, the polymer layer makes the roof very beautiful and attractive. And now we consider them all in order.

Brilliant Polyester - requires careful handling

This PE coating is indicated, and it is used in seven of the ten metal-tile roofs that are being laid today. However, polyester is covered not only with shingles, but also with some varieties of sheeting. Polyester is inexpensive, but does not always withstand the aggressive influence of the atmospheric environment. In addition, it is easy to damage during careless loading or transportation. The metal tile with such covering will live from 5 to 10 years. Its thickness is 25 microns. Polyester tolerates winter cold badly, but at temperatures ranging from 0 to plus 90 degrees Celsius, it feels great.

- Advanced. . See left or leave your reviews about the polymer coating polyester .

Noble Matte Polyester

It can have various designations: MPE (mostly), MatPE, Matpol, PEMA. Because of the Teflon, introduced into the composition of the most ordinary polyester, the type of coating varies dramatically. It no longer shines, more enduring weather cataclysms and serves at least 15 years. Its thickness is 35 microns. The temperature limit is the same as the previous coating.

The Strongest Pural

The basis of this coating is polyurethane, which gives shingles resistance to ultraviolet radiation. The layer of pural is mechanically more difficult to damage than other coatings; it is not afraid of aggressive chemical reagents. Temperature jumps from “plus” to “minus” (from -60 to +100 degrees) and long autumn rains are not able to spoil this coating either. It gives the roof the opportunity to serve up to 30 years. Thickness - 50 microns. However, tiles with such a coating are significantly more expensive than the two previous types.

Matte Pural

This coating is also called MPURA, as well as PUMA, PURALMATT, MatPUR. The thickness of the protective layer and the temperature limit are the same as in the previous material.

- Advanced. . Izuchaty left or leave a piece and reviews of metal tile with a polymer coating Pural.

Purex

This cover is the brainchild of Ruukki (Finland). It is not only beautiful, but also very plastic. The tile covered with Purex is not afraid of corrosion and mechanical damage. The manufacturer gives a guarantee up to 50 years.

Prisma - polyurethane protection

The British came up with this coating (specialists from the Corus plant). In its composition, in addition to polyurethane, there is an alloy called Galvalloy. It consists of 95 percent aluminum and 5 percent zinc. The manufacturer guarantees the roof with such a coating for at least 15 years of life. During this time, metal does not take any corrosion or mechanical damage.

- Advanced. . Study left or leave your reviews about metal tile with a protective coating prism .

Plastisol - PVC coating

This coating, which has a very solid thickness (from 100 to 200 microns), has plasticizers added to polyvinyl chloride. The outer texture is similar to the skin or birch bark.It should be noted that the varieties of metal with a plastisol coating are well suited for organizing drains or creating roofs for sheds and other economic structures. Temperature limit - from plus 10 to plus 60 degrees Celsius.

PVDF coating - excellent weather protection

The tile covered with this material not only looks very elegant. She also copes well with attacks of corrosion, perfectly withstanding all the unpleasant weather "surprises". Coating thickness - 27 microns. This is quite enough to withstand heat, cold and hail storms.

Kami TerraPLEGEL - composite metal tile

It is a multilayer coating consisting of 2 layers of polymer, quartz sand and an outer layer of polyester. Due to the quartz sand layer, the coating is the most resistant to mechanical damage. Terraplegel has a rough surface imitating natural tile, it does not shine in the sun and muffles the sound of rain, which is very important for metal tiles.

Solano

The Solano coating has an original dotted texture. The thickness of the polymer layer is 200 microns. It is not subject to mechanical damage and perfectly protects against corrosion. Manufacturer's warranty up to 50 years.

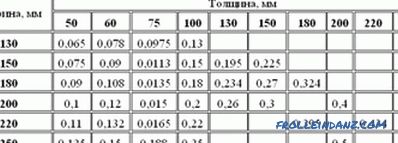

Comparison of technical characteristics of polymer coatings of metal tiles

| Type of coating | Thickness, μm | Max. temp. , 0 C | Min. pace. are flexible, 0 C | Resistance. fading | Resistance to corrosion | Resistance to fur. air | Lifetime. | years

|---|---|---|---|---|---|---|---|

| Glossy Polyester | 25 - 28 | 120 | - 10 | Low | Medium | Low | 10 |

| Matte Polyester | 35 | 120 | - 10 | Average | Average | Low | 15 |

| Pural | 50 | 100 | - 15 | Average | High | Average | 50 |

| Matte Pural | 50 | 100 | - 15 | High | High | Average | 50 |

| Purex | 26 | 100 | - 15 | Average | High | High | 40 |

| Prisma | 50 | 120 | - | High | High | Average | 20 |

| Plastisol | 200 | 60 | + 10 | Medium | High | High | 30 |

| PVDF | 27 | 110 | - 10 | High | High | Low | 35 |

| Solano | 200 | 60 | + 10 | High | High | High | 70 |