Built-in wardrobes have long been guests in most apartments. They save space. They can put a variety of items. It does not have to be clothes or shoes. Household items or dishes can be stored here.

Drawing of the built-in wardrobe.

The modern market offers many different models of built-in wardrobes. However, not all of them are of high build quality. In most cases, really good furniture is worth the money.

However, you can make a built-in closet with your own hands. Today you can buy almost any material for this purpose. Construction and furniture stores often distribute everything you need. So they can be found even in the smallest city. To make such a wardrobe is quite easy. This is worth talking in more detail.

Selection of materials: which is better?

First you need to decide on the material that is best suited for such a cabinet. There are several basic options. They all have a place to exist. In this case, the person should choose a specific material himself. Here only advantages and disadvantages of various kinds will be given.

Plywood

Plywood is quite durable and durable, so furniture made from it serves for many years.

It has been used for a long time by man in the manufacture of furniture. For the built-in closet with your own hands, it also fits. A distinctive feature of plywood is its high strength and durability. Many elements of furniture, made on its basis, have been serving for decades. However, this material also has its drawbacks, which we will have to put up with in the course of work and further exploitation.

The most important negative point is the difficulty of processing this material. It is not easy to cut even pieces. Often, working independently with such material is not recommended. If plywood was chosen to organize the built-in wardrobe, then you should take care to cut it in advance in size in the store. This is the only way to eliminate all misunderstandings.

Plywood tends to stratify under the influence of water or other liquid, so if you plan to install a cabinet in the kitchen, you should not use this whimsical material to make it. In other cases, you can take it as a basis.

Chipboard

Chipboard is quite simple to process and therefore has a huge demand, but it has a disadvantage - it is not the most eco-friendly material.

A material that deserves respect among many people. It is him in most cases that a person uses for arranging built-in wardrobes. It has high strength, reliability and durability. In addition, it is quite easy to handle using any tool. This is an undoubted advantage and is fundamental in the design of cabinets. There are also its drawbacks.

Chipboard is produced in the form of huge sheets. It is not always convenient to work with them. For dressing you have to do everything in every way. However, in this case it is possible to provide the possibility of cutting to specialists in the store. The main thing is to prepare in advance all the sizes and write them out on a piece of paper.

Plastic

The advantages of plastic are: long service life, resistance to mechanical stress, moisture resistance, heat resistance and immunity to fats, chemicals and oils .

Similar material has already entered our life for a long time. It is not always used for the production of furniture, but sometimes even built-in wardrobes make it from it. Plastic has a number of undoubted advantages that make it one of the leaders of the modern construction market. It is fairly easy to handle almost any tool.

It does not require any specific skills. During operation, the cabinet will be easy to clean. To do this, you can use the most ordinary cloth dipped in water. This material is not afraid of any liquids, even aggressive ones. Chemical components can also be used for washing. These benefits affect buying activity. The disadvantages are also palpable. Plastic is not as organic as natural building and finishing materials.

Furniture panels

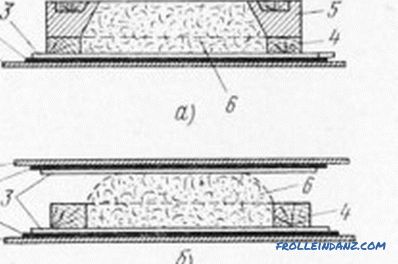

The scheme of forming the packages of furniture panels with particle size: a, b - the order of operations; 1 - metal gaskets, 2 - finishing cladding, 3 - blister cladding, 4 - shield frame, 5 - forming frame, 6 - chip filling.

They are the best option for making your own built-in wardrobe. They are produced 18 mm thick.

At the same time, it is fairly easy to cut them into pieces, since they are not as bulky as LDSP boards.

Ideal for almost any occasion.

Of course, they are not suitable when it comes to designing a large cabinet.

Here you have to look for alternative materials.

The choice of material remains with the person. Our goal is to show their benefits.

Required tools

These are:

- tape measure;

- jigsaw;

- pencil or marker;

- screwdriver;

- glue;

- sandpaper.

Selection of fittings and fasteners

In order to work with the cabinet brought only pleasure, it is necessary to select only high-quality accessories for it. Here we are talking about the wheels, guides and handles. All these elements without special problems can be purchased today in specialized stores. Guides are selected roller. It is necessary to ensure that the rollers themselves were made from quality materials.

Detailed assembly scheme of the wardrobe compartment.

It can be plastic or metal. The main thing is that the assembly was of good quality. As for the handles and loops, then you can pick up any standard version. The most important thing is that their colors and appearance should exactly match the interior, where you will have to stand in the closet.

Fasteners will be used the most diverse. His choice depends on the material from which the built-in wardrobe will be made. You can use and screws, but it will definitely need to take care of the acquisition of special plastic or wooden linings. They ideally hide all design defects.

Such linings can also be purchased at furniture stores. Wooden dowels will look good if the design is done with the help of furniture panels or plywood. It all depends on the material that was chosen as the basis for the manufacture of the cabinet.

Assembly of the built-in cabinet

No matter what material is used to make the built-in cabinet, the principle of its construction will be the same for all cases. To begin with, it is necessary to make all the necessary markings on the material in accordance with the drawing. This is done with the help of measuring and drawing tools.

Before work, it is worth clearing the place where the cabinet will be installed. Then deal with the marking. Most importantly, correctly position the guides so that they allow you to easily slide in and open the drawers.

To the door panels it is necessary to fasten aluminum profiles with self-tapping screws, which should be cut in advance.

The wardrobe door assembly scheme.

Before installing the rollers, be sure to pull out the special mounting screws that are supposed to be their construction. Large wheels are installed at the bottom and small ones at the top. So the load will be distributed evenly. After that, the screws must be tightened. This will connect the profile and the door leaf.

After the profiles are attached to the canvases, you need to make holes for the rollers. You shouldn’t do this right away, as it may interfere with long-distance assembly work.

Now you can proceed to the next stage of work, which is the installation of sliding doors. To install the door guides little effort of one person. We'll have to invite an assistant who will work with you to adjust them. Otherwise, it is likely that the door will skew.

Special adjustable feet are installed for height leveling. The rails are attached to the ceiling, and then ready-made door leafs are inserted into them. Only then is the bottom guide installed. Now it can be safely fixed with screws.

This stage was not the final one, since in the course of the previous work only the bare box was obtained. It must be filled with internal content.

The interior of the built-in cabinet can be varied. Some people prefer to install modest fixed shelves in it. Some comrades make retractable cabinets. It all depends on the desire of the person and his capabilities. Simple shelves are much easier to do than equipping drawers. Here the main thing - to make the correct calculations of all components.

For arranging regular shelves, the same shield that was used for the installation of the main structure will do. Before the inside of the cabinet it is necessary to make markup for these shelves. Attach them in various ways. It is best to use wooden dowels in this situation. The number of shelves can also be very diverse. It all depends on the functional purpose of the built-in closet.

Some features

If we talk about drawers, then they are best done from chipboard. This material is easily processed. For their arrangement will need guides. In this case, it is suitable roller options. They are mounted strictly in a horizontal position.

For leveling it is best to use a level. Liquid tools should always be at home in stock. The sliding wardrobes themselves are extremely simple. For ease of use you can attach special handles to them.

You can make a built-in wardrobe, in which there will be both sliding wardrobes and ordinary shelves. In this case, it will be universal. Here you can store almost any clothes. Doors are sometimes made with glass windows. This allows you to see all that is inside. As a result, the work is a wardrobe, which is currently very popular among the inhabitants of our country.

Didn't find the answer in the article? More information on the subject:

-

Assembling wooden partitions with your own hands

To mount wooden partitions with your own hands, you need to prepare a timber. Its size will depend on the size and weight of the future septum. If necessary, the base must be strengthened.