The number of types of wires, electrical cords and cables amounts to tens of thousands - only more than 20,000 registered by domestic GOSTs are registered. The good news is that you don’t need to know face to face all existing types of cables and wires and their purpose is enough dividing them into types and being able to read the label, which displays all the important characteristics.

Basic concepts

The characteristics of any cable or wire are determined by the properties of their conductive wires and the surrounding insulation.

A wire lived in a wire

A wire is a metal wire that is capable of passing an electric current through itself. It has two important characteristics - the number of wires from which it consists, and the cross section that determines the throughput.

By the number of wires, the wires are divided into single-wire (monolithic) and multi-wire. This parameter determines the flexibility of the core - the more wires there are, the easier it is to bend. Pay attention to this when choosing a wire or cable for specific purposes - if the wiring in the walls can be made with single-wire conductors, then to replace the power cord of the electric device, you must take wires with multiwire conductors. There is no insulation between the individual wires of a multiwire core - usually they just twist together.

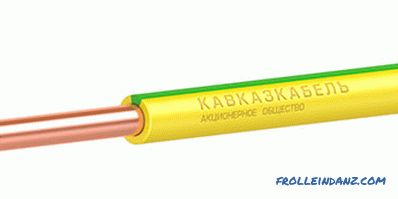

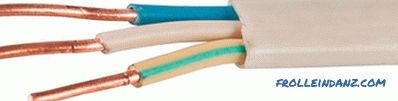

Single-wire core.

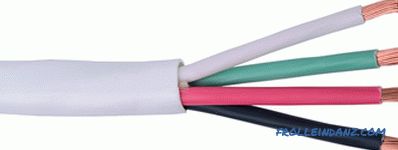

Multiwire conductor.

The sectional area of the conductors determines the total power of the current that can be passed through it. Since the cross section of the wire is the main parameter used in the calculation of the capacity of the electrical wiring, manufacturers are required to indicate it to the conductor insulation. To eliminate confusion, this is done at regular intervals - usually up to 1 meter, and if the wire is bare, then the cross section is indicated on the packing of the bay, but it is advisable to double-check it with a caliper or micrometer. You also need to be careful when buying inexpensive brands of wires - there are certain tolerances for the thickness of the conductor cores in the GUEST, and sometimes manufacturers actively use these. For example, there are brands of wires with a tolerance of as much as 30%, and if the accuracy of the equipment allows, then instead of 1 mm² you can get conductors with a cross section of 0.75-0.8 mm² and everything will be within the law.

There are also differences in the veins in shape - they are mostly round, but in a number of varieties of wires and cables are made, for example, sector ones - single and multi-core. This improves the overall layout of the cores and reduces the outer diameter of the entire product.

Insulation of electrical wiring

The main task of the insulating dielectric layer is to protect a person from contact with the conductor. Also, the presence of insulation allows you to put several lived side by side, without fear of a short circuit between phase and zero (the contact of the phase conductor with the ground) or other phases.

Certain dielectrics are used for various purposes: ceramic or glass, and for flexible cables and polymeric wires - polyvinyl chloride or celluloid. Polymer insulation is most often used for household wiring - its properties make it possible not only to protect the conductors from short circuit, but also to protect them from mechanical damage, high humidity and other external factors.

Armored wires and cables are also made, with multilayer insulation, inside which there is an additional braid or steel tape. They are used on unstable soils, when laying the line under roads and in similar conditions.

What are the differences between a cable and a wire

The same conductors of electricity can be called a cable, wire or cord. At the same time, to tell the truth, both buyers and some sellers do not particularly bother themselves with the correct wording.

Wire - base

By definition, a wire is one or more live conductors that connect two sections of an electrical circuit. The veins can be single and stranded, bare or insulated and differing in other characteristics. There is also a separate category of protected wires, which are easily confused with the cable, due to the presence of the outer sheath - each core has its own insulation, and all together outside is additionally closed with a crib of polymers or similar materials.

Bare wires are practically not used in domestic conditions - they are more often used to transmit electricity through overhead lines and in other places where a person does not fall without access.

Insulated wires themselves are poorly used in everyday life - the more they are used inside various electrical equipment or in the electric vehicle electrical network.

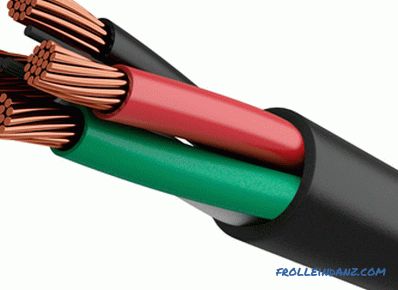

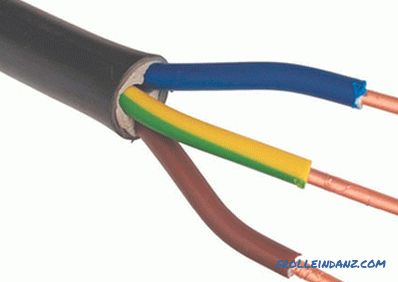

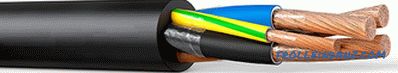

Cable - prefabricated construction

The structure of the cable is similar to a protected wire - it is one or more current-carrying veins, each of which is in its own insulation, plus one more Insulating protective outer layer of polymers, plastic or rubber.

The main difference between a cable and a wire is to look inside - if the latter has an outer sheath just a tube, then the cable additionally fills the space between the current-carrying conductors - threads, tapes or coated compound. This prevents the cores from sticking together, which may slightly shift relative to each other when the cable is bent, which simplifies its installation and further maintenance.

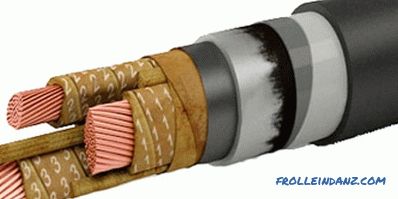

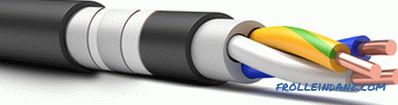

Additionally, armored cables stand out - they have several layers of outer insulation, between which there is protection against mechanical damage in the form of braid or intertwined metal tapes.

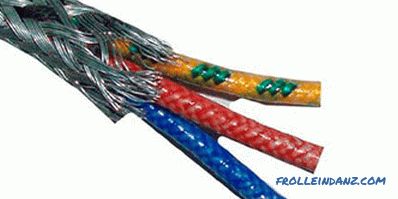

Cord - Flexibility

The main use of electrical cords is to connect household appliances to the network. They must have increased flexibility and resistance to repeated bending, therefore copper multiwire cores with a total cross section up to 4 mm² are used in the cords.

In order to avoid overconsumption of copper in the production of devices, the section of cords is selected depending on the power of the connected devices. For small electrical appliances, like an electric shaver, this will be 0.35 mm², 0.5 mm² is enough for televisions, and devices with an electric motor from 0.75 mm².

The length of the cords is not strict standards, but most often it is 1, 1. 5, 2, 3. 5, 4 and 6 meters. Often, electrical devices are equipped with cords with non-separable (disposable) plugs, and for some devices, reinforcement is woven under the outer insulation to increase mechanical strength. If you have to change the electrical cord on the device with heating elements: iron, boiler, kettle or electric stove - we must bear in mind that the insulation must be with high heat resistance.

As a result - the main differences

An independent and separate unit is a wire - bare or insulated. Several insulated wires assembled in a bundle and twisted among themselves is also a wire, but stranded. If there is additional insulation on top of the stranded wire, this is a protected wire. If there are additional elements between the conductors of the protected wire: reinforcing filaments, coating or part of the outer sheath is “recessed” between the wires, then this is already a cable. A flexible wire or cable made to connect to a network of electrical appliances is called a cord.

Distinction of cables and wires depending on the material of the core

The cores of wires and cables of specialized purpose can be made of various metals, but mainly aluminum and copper are used in electrical engineering. Each of them has its own specific properties, advantages and disadvantages that must be considered when selecting the core material for a specific purpose.

Aluminum conductors

The invention of a relatively inexpensive method of mining aluminum made a revolution in the global development of electrification, because by the level of electrical conductivity this metal is in fourth place, passing only silver, copper and gold forward. This made it possible to make the production of wires and cables as cheap as possible and to make general electrification a reality.

Such electrical wires and their types are distinguished by low cost, chemical resistance, high level of heat transfer and low weight - they determined the mass electrification in industrial and living conditions for more than half a century.

In the light of the relatively recent domination of aluminum on the wire market, it may seem strange to an uninitiated person to prohibit TIR from using this material in everyday life for the uninitiated. More precisely, aluminum wires with a cross section of less than 16 mm² cannot be used, and these are the most common ones for the installation of household wiring. Understand why there is a ban on the use of these wires can be introduced to their strengths and weaknesses.

+ Pros aluminum wires

- Easier than copper.

- Significantly cheaper.

- Cons of aluminum wires

- Aluminum cores with a cross section of up to 16 mm² can only be single-wire, which means that they can only be used for laying fixed wiring and without bending at an acute angle. All flexible wires and cables are always made of copper.

- The chemical resistance of aluminum is determined by the oxide film, which is formed upon its contact with air. Over time, with constant heating of the contact due to the flow of electric current through it, this film degrades the electrical conductivity, the contact overheats and fails. That is, aluminum wires require additional maintenance, and the contacts through which powerful currents pass are coated with a special lubricant.

- Amorphous material - if you hold two aluminum wires together, the contact will weaken over time, as the aluminum will partially "flow out" from under the yoke.

- Soldering can be carried out only with the use of special means, and welding will be performed in a chamber with an inert gas.

- Good electrical conductivity is observed only in pure aluminum, and impurities that remain unavoidable during production worsen this indicator.

As a result, aluminum is a good choice to save here and now if necessary, but in the long run its use will be more expensive due to its relatively low life and regular maintenance. . For this reason and for additional safety reasons, it is strictly prohibited to use it for laying new power lines.

Copper conductors

Copper is second in electrical conductivity, only 5% lower than silver by this indicator.

Compared to aluminum, copper has only 2 significant drawbacks, due to which it has been used much less often for a long time. Otherwise, copper wins in all respects.

+ Pluses of copper wires

- Conductivity in 1 7 times higher than aluminum - a smaller cross-section of the wire will pass the same amount of current.

- High flexibility and elasticity - even single-core wires withstand a large number of deformations, and cords for electrical appliances of increased flexibility are obtained from stranded.

- Soldering, tinning and welding are carried out without using additional materials.

- Cons of copper wires

- Cost - several times more expensive than aluminum.

- High density - a coil of copper wire of the same length and cross section with aluminum will weigh 3 times more.

- Copper wires and contacts oxidize in the open air. However, it practically does not affect the transitional resistance and in case of necessity it is “cured” by lubricating the surface of an already prolonged contact.

As a result, although copper is a more expensive material, in general, its use is more economical, since it is more durable, requires less effort during installation and attention during maintenance.

Distinction of cables and wires depending on insulation

In a cable or a protected wire, insulation is divided into internal, covering each core separately and external (external). The first protects the wires from contact with each other and protects them from mechanical damage. Outdoor keeps all cable components together and additionally protects internal insulation from drying out, moisture, and other factors.

Insulation Characteristics

When selecting insulation, its ability to withstand is taken into account:

Voltage . In domestic conditions, this issue is not given special attention, since the vast majority of materials can withstand up to 660 or 1000 volts.

High temperature . With the passage of current through a conductor, part of the energy is dissipated in the form of heat, which is dispersed from the surface of the insulation in the environment - air, if it is open wiring or goes into the wall, if closed. At a certain point, equilibrium occurs when the amount of heat released is compared with the heat given off. The temperature that is set at this point must be in the range of the so-called operating temperature, which the insulation of the wire must withstand indefinitely. For short-term overloads, there is also a temperature limit, which the insulation without consequences must withstand for a certain time. The behavior of the insulation is also indicated in case of excessive heating - burning, smoldering, the release into the air of substances harmful to humans and other.

Low temperature . If the cable will be used outdoors, you must additionally look at the frost resistance indicator - at a certain subzero temperature, the insulation becomes fragile, which must be taken into account during installation and further operation.

UV resistance . Part of the insulating materials, with other excellent characteristics, begins to deteriorate over time, if it is under the influence of sunlight. They become brittle and shrivel - this must be taken into account, if it is planned, for example, to conduct wiring to a veranda or summer house.

Mechanical tensile strength . The more, the better, although, of course, there is no point in taking a heavy-duty cable to repair a wire from a light bulb.

Insulating materials

A large amount of insulating materials are used in electrical engineering - even just to list them all is quite difficult.But at the household level, it is enough to know those of them that are used most often - for internal wiring and supplying electricity to the house.

Polyvinyl chloride (PVC).

Due to its low cost and good physical characteristics - flexibility and durability, it is most often used to insulate wires that are laid indoors. Not flammable and sufficiently resistant to aggressive chemical compounds. The disadvantages include the inability to withstand temperatures below -20 ° C, and the release of caustic substances when excessively heated.

Rubber.

Natural material used when it is necessary to obtain increased wire flexibility and resistance to freezing temperatures.

Polyethylene.

A good dielectric, resistant to negative temperatures and aggressive chemical compounds \, but flexibility leaves much to be desired.

Silicone rubber.

A distinctive feature of a material is its property to form a film that does not allow an electrical current to flow after burning. This reduces the likelihood of a short circuit due to overheating of the wiring.

Impregnated paper.

A good dielectric, but how much it is protected from overheating depends entirely on the substance used for impregnation.

Carbolite.

A good insulator with high heat resistance is soft and plastic material. In addition to insulation, it is used in the manufacture of sockets and similar devices. Of the shortcomings of the material stands out its fragility.

Additional elements of external insulation

Depending on the purpose of the cable, in addition to external insulation, the following elements are added:

Escaping.

Most often used in low-current data cables and made of foil or additional braid. The purpose is to create a barrier against parasitic currents that can be directed from radio waves or radiation from neighboring electrical appliances. Additionally, align the electromagnetic fields inside the wire itself.

Reservations.

Braid made of fairly thick metal. Maximum protection of the cable against possible mechanical damage - is used when laying on moving soils or those that are subject to constant mechanical stress - under motorways, etc.

Cotton sheath.

Additional protection for external insulation from mechanical damage, plus protection from rotting, for which the braid is impregnated with chemicals.

Galvanized steel braid.

Protection of the wire from mechanical stretching is necessary for those cables that have the risk of sharply jerking during the operation of electrical equipment.

Types of wires

The selection of the desired wire depends largely on the power of electrical devices that will be fed through it. Next, we consider the different types of wires that are most often used for domestic use.

Flat

1. PBPP (PUNP).

Flat protected wire with single-wire copper conductors with a cross section from 1.5 to 6 mm² located in one plane. The material of the outer and inner insulation - PVC. It can be used at temperatures in the range of -15 / + 50, during installation it is allowed to bend around a circle with a radius of at least 10 diameters (since the wire is flat, width is measured - the larger side). It is intended for transfer of current up to 250 Volts, with a frequency of 50 Hertz. Used primarily to connect lighting or outlets.

2. PBPPPG (PUGNP).

The letter "g" in the title indicates the distinguishing feature of the wire - the flexibility that the use of multiwire conductors gives. It also reduces the bend radius during installation, which is equal to 6 diameters. All other characteristics are the same as the single-wire PBPP (PUNP).

3. APUNP.

The same wire PUNP, but with a single-wire aluminum core, with a cross section of 2.5 to 6 mm². The remaining characteristics are unchanged.

When purchasing wires for PBPP, PBBPPG and APUNP, it is necessary to remember that GOST defines for them the tolerance on thickness of the core and insulation of 30%. This means that, in fact, the cross section of the wire with a marking of 1.5 mm² may well be ≈1 mm². In addition, the AUPNP wire is prohibited for use by the provisions of the ПУЭ, and it is made only because of the demand caused by the low price.

Although the insulation of such wires must withstand voltage up to 250 Volts, but for the above reasons, this is not always the case. Therefore, it is better to use them only for lighting, and for sockets to purchase NYM or VVG cables.

With jumpers

1. PPV.

The wire is easy to recognize thanks to the characteristic bridges between the wires that are made of the same material as their insulation - PVC. The number of veins themselves was 2-3, they were single-wire, with a section of 0.75-6 mm². The wire can be used to transmit a current of 450 Volts and frequencies up to 400 Hertz. Insulation does not burn, is resistant to acids and alkalis - after installation, the wire can be used at temperatures of -50 / + 70 ° C and in conditions of 100% humidity (characteristic for 35 ° C). At installation the bend with a radius of 10 diameters is allowed.

2. APPV.

The same characteristics as the PPV, but taking into account the aluminum conductors - the section starts with 2.5 mm². Appointment - installation of open conducting - lighting and power.

Single cores

1. AR.

Separate aluminum solid wire. The core with a cross section of 2.5-16 mm² is single-wire, and 25-95 mm² is multi-wire. Insulation material - PVC, resistant to chemically aggressive compounds, allows the use of wire at a humidity of 100% (tests at 35 ° C), in the temperature mode -50 / + 70 ° C. When mounting, observe a bending radius of 10 diameters. There are no special restrictions for use.

2. PW1.

The same AR, only with a copper single-wire core, section 0.75–16 mm² and multi-wire 16–95 mm².

3. PW3.

The number in the wire name indicates the flexibility class - here it is much higher, since for any cross-section of the core it is multi-wired. It is used for installation of lines where frequent transitions and bends are needed. The radius of the latter should not be less than 6 diameters.

The wires PV1, PV3 and APV are made with multicolor insulation, which increases the convenience of their use for the installation of switchboards without the use of additional marking.

For the manufacture of electric cords

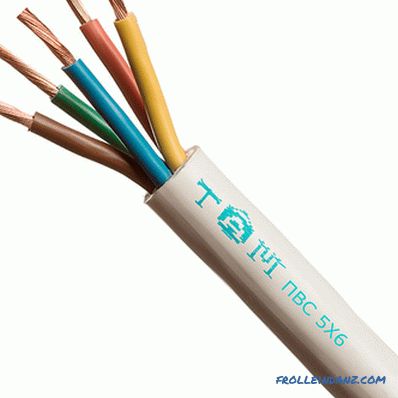

1. PVA.

Copper stranded wire with 2-5 stranded conductors with a cross section of 0.75-16 mm². The insulation of all the conductors of different colors, the shell is plain white. The purpose of the wire is the transmission of a current of 380 volts with a frequency of 50 hertz. Due to the high flexibility, it is most often used for connecting electrical equipment - it is designed for at least 3000 flexings. It is not recommended for laying inside walls - in such conditions, after 4-5 years, external insulation will begin to break down. It can be used at temperatures of -25 / + 40 ° C, and in the modification of PVU - from -40 to +40 ° C.

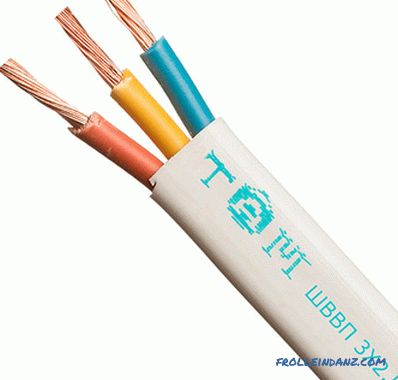

2. ShVVP.

Copper stranded wire, with 2-3 multi-wire cores of increased flexibility with a cross section of 0.5-0.75 mm². Used for the manufacture of power cords for lamps or low-power electrical devices that require voltages up to 380 volts and a frequency of 50 Hertz. Not suitable for installation inside walls.

Types of cables

In addition to standard power cables designed to transmit electric current, there are a number of additional modifications that are used for other purposes or have separate functions.

Power Cables

The main purpose of power cables is to lay indoor or outdoor electrical wiring to power the lighting devices and sockets. Most often, the following types of cables are purchased for this:

1. VVG.

One of the most popular and reliable domestic power cables. It is used to transmit electric current with voltage up to 1000 Volt and frequency of 50 Hertz. Depending on the modification, single and multiwire conductors with a section of 1.5-240 mm² are used. External and internal PVC insulation protects the conductors from high humidity - up to 98% at a temperature of +40 ° C. Popular modifications of the VVG cable:

AVVG - the same VVG, but with aluminum single-wire cores with a cross section of 2.5-50 mm².

VVGng - the insulation does not support combustion.

VVGp is a flat cable in which the conductive wires are located in the same plane.

ВВГз - between the outer and inner insulation there is a filling in the form of rubber chips or additional PVC threads.

All types of insulation have good mechanical and chemical resistance, bending radius from 10 diagonals.

2. NYM.

By its structure, this is an analogue of the VVG cable, but not made by domestic guests, but by European standards developed by German engineers. With equal physical characteristics cable NYM is considered more reliable, since the materials that are used in its production, better, and tolerances tighter.A distinctive feature of the cable is a layer between the inner and outer insulation of coated rubber

By its characteristics and purpose, NYM is a household cable for mounting sockets or lighting - it consists of 2-5 conductive multi-wire copper conductors and is designed for a voltage of 660 Volts . The quality of the insulation allows the cable to be operated at temperatures of -40 / + 70 ° C, and the bending radius during installation is only 4 diameters.

The NYM cable is used for external and internal wiring. There are only two restrictions - to prevent exposure to direct sunlight and not to lay the cable directly into the freshly cast concrete - in such cases it is necessary to use corrugated pipes or cable channels.

Depending on the number of cores, their insulation is painted in the following colors: black, blue, yellow-green, brown, and another black with an additional label.

3. KG - flexible cable.

1-6 stranded copper conductors are designed for AC voltages up to 660 Volts and frequencies up to 400 Hertz. The material of internal and external insulation is rubber, which gives the cable increased flexibility and makes it possible to operate at temperatures of -60 / + 50 ° C.

Primarily used for connecting to the network of powerful electrical equipment - welding machines, heating devices, generators, etc. If necessary, you can also use it for mounting power wiring, but this is quite expensive - if possible, it is easier pick up NYM or VVG.

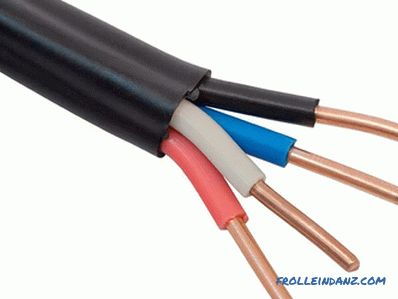

4. VBBSHv.

Copper cable with single or stranded conductors with a section of 1.52-240 mm², in the amount of 1-5 pieces. External and internal insulation are made of PVC - all voids between the veins are filled with the same material. Under the outer shell is made of armor of two metal tapes that are wound overlap. The insulation withstands voltage up to 1000 volts and can be operated at temperatures of -50 / + 50 and humidity up to 98% (at +35 ° C).

The following modifications are common:

- AVBBSHv - with aluminum conductors.

- VBBShvng - isolation does not burn.

- VBBShvng-LS - insulation during smoldering almost does not emit smoke and caustic gas.

When installing, the bending radius must be maintained from 10 diameters.

5. Glowing cables.

When such a cable is plugged into the network, the surface of its insulation starts to glow.

This effect is called in two ways:

LEDs . External insulation is made in two layers, one standard and the second transparent. Between them at a distance of 2 cm in series to each other are LEDs. This design is very convenient in terms of searching for a broken current-carrying core - in this place the LEDs will no longer glow. Such cables are manufactured by Duralight - most often they are used to power stage equipment, but there is a line of luminous computer cables.

Fluorescent coating . When turned on, the network emits a uniform luminescence of the entire area, which resembles neon tubes. The advantages of this solution are relatively low cost and no restrictions on the length of the cable.

Cables for transmitting information

The earliest of them were used to connect telephones and television antennas, but with the development of computer technology, new types of cables for transmitting information appeared.

1. RG-6, RG-59, RG-58, PK75.

To a non-specialist, such cables are better known as "antenna", which consist of a single or stranded copper conductor with a cross section of about 1 mm², thick internal insulation made of dense polyethylene foam, shielding braid and an outer insulating layer - cambric.

Without going into technical details, it is enough to know that such a cable structure is ideal for transmitting low-current high-frequency signals. Specialist, when buying such a cable, will ask about such characteristics of the transmitted current as frequency, resistance, type of shielding, signal decay time, etc.

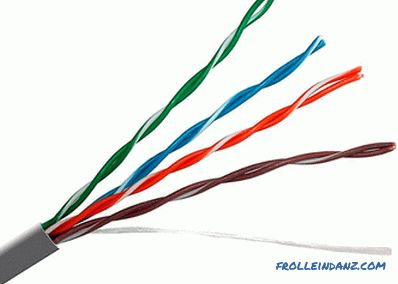

2. Computer twisted pair.

If a special fiber optic cable is used for long distances, the so-called twisted pair is used to connect computers to local networks. Most often it is 4 or 8 wires intertwined with each other in pairs - this design improves the characteristics of reception and transmission of a signal.

Since the twisted pair wires are usually thin and can be easily damaged, there is a bursting wire next to them, which can be easily cut through and cut from the outside by external protective insulation.

There are several types of such cables, differing from each other by the presence or absence of additional shielding to stabilize the signal passing through the cores:

- UTP - with conventional external protective PVC isolation.

- FTP - a foil screen is wound under the outer insulation.

- STP - the screen is made in the form of a braid of copper wire. In addition to general shielding, each twisted pair is protected separately.

- S / FTP - foil shield under common insulation and on each twisted pair.

By the number of twisted pairs, the cables are divided into categories CAT1, CAT2 and CAT5e - the last of them is 4 pairs of wires, which allows you to transfer data at speeds up to 1 Gb / s.

3. Telephone cables and wires.

Low-current cables - are divided mainly into those used when laying the line between telephone substations and for mounting individual branches in a house or apartment.

TPPep. Stranded cable - depending on the modification, it is designed to connect up to 400 subscribers (each has 2 wires). The conductors are single-wire, with a cross section of 0.4-0.5 mm², insulation - polyethylene. In addition to modifications by the number of wires, there are armored cables suitable for laying in the ground without additional structures.

TRV (noodles). 2 or 4 single-wire copper conductors with a section of 0.4-0.5 mm², enclosed in a PVC sheath with a divided base. Insulation withstands operation at temperatures of -10 / + 40 ° C and relative humidity not higher than 80% (at +30 ° C).

TRP. The same TRV, but with polyethylene insulation, which makes the wire suitable for outdoor use.

STPS. Flat protected wire of increased flexibility with two or four stranded conductors with a cross section of 0.08-0.12 mm². Internal PVC insulation, outer layer - polyethylene.

PRPM. Flat, protected two-core wire with single-wire conductors with a cross-section of 0.9 or 1.2 mm² and a divided base. Depending on the modification, the internal insulation is made of PVC, and the external one is made of polyethylene or double PVC. The wire is suitable for operation at temperatures of -60 / + 60 - used for laying the outer line on the walls of buildings or on air supports.

Specialized cables

Designed for operation in non-standard conditions — with different temperatures, humidity, pressure, etc. from the standard ones.

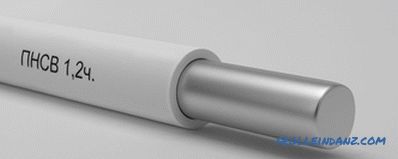

1. PNSV.

A heating wire designed not to transmit, but to consume electricity. A vein with a cross-section of 1. 2, 1. 4, 2, 3 mm² is made of steel and is coated or galvanized. Insulation of heat-resistant PVC or polyethylene, which retain their properties in the temperature range -50 / + 80 ° C. The wire is designed for connection to the line 220-380 Volt 50 Hertz and is most often used for the manufacture of underfloor heating.

2. runway.

Cable with a copper stranded conductor with a cross section of 1.2-25 mm² enclosed in double insulation made of polyethylene or PVC. Designed to operate at voltages up to 660 volts and a frequency of 50 Hertz. The insulation withstands abrupt changes in pressure and allows cable operation at temperatures of -40 / + 80 ° C. A popular area of application is to power the motors of pumps lowered into artesian wells.

3. GCGM.

Power copper single-core thermostable installation wire. A multi-wired flexible core with a cross section of 0.75-120 mm² - designed for voltages up to 600 Volts at frequencies up to 400 Hertz. Insulation of silicone rubber with an outer shell of fiberglass, plus the impregnation of heat-resistant varnishes or enamels - retains its properties in the temperature range -60 / + 180 ° C. These types of wires are used for operation at repeatedly elevated temperatures - wiring in furnaces, baths, connecting heating devices, etc.

Marking of cable products

The alphanumeric designations that make up the name of the cable displays in itself all the most important information about its characteristics: what the veins are made of and the insulation, the purpose and design differences, the number and cross section of the veins, additional features. Some of the letters may be absent, thus denoting any common parameter.

Letter 1. It can only be "A" - it means an aluminum conductor. If the marking starts with any other letter, then the first one is missing and the cable is copper.

Letter 2. Indicates for what purpose the cable is:

- M - installation

- MG - flexible installation

- П (У) or Ш - installation

- К - control

The absence of the second letter indicates that it is a power cable.

Letter 3. Material and type of internal insulation. The most common designations:

- P - polyethylene

- B or BP - polyvinyl chloride

- P - rubber

- H or HP - non-flammable rubber

- С - fiberglass

- К - kapron

- Д - double winding

- W - polyamide silk

- E - shielded

Letter 4. Design features:

- G - flexible

- K - armored, braided with round wire

- B - armored with ribbons

- O - in braid

- Т - laid in pipes

Extras. Letters - lowercase in Cyrillic or Latin capital letters, indicate features of the cable subspecies:

- h - filled

- ng - non-combustible

- HF - emit when burning low smoke

- LS - emit little gas

Figure 1 when burning. Number of veins.

Figure 2. Conductor cross-section.

Digit 3. The rated voltage for which the wire is designed.

This is far from all possible designations — only those used in widely used cables and wires for domestic use. If necessary, you can look at the decoding on the tag or ask the seller.

Example of marking decoding: AVVGng 3x2. 5

- A - cable with aluminum conductor;

- B - insulation of each PVC conductor;

- B - PVC outer sheath;

- G - flexible cable;

- ng - the shell does not support burning;

- 3 - three cores;

- 2.5 - section veins.