Cottage is a wonderful resting place for the whole family. It is interesting to spend time, to fully relax and have dinner with the whole family in the case when the dining area is properly equipped and equipped.

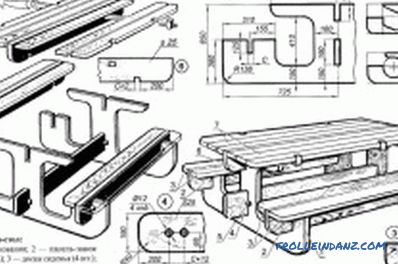

Table device for the garden.

An important piece of furniture for dining and recreation in a country house is a table. It should be made of eco-friendly and durable materials, different attractive design and functionality. Consider the question of how to make a table for giving your own hands.

Advantages and disadvantages of a wooden table

Plastic materials, metal, and combinations of materials are often used in the manufacture of country furniture. The most affordable material is durable and practical wood that is easy to process, always available in the consumer market. A table made of wood with its own hands has a lot of advantages:

- has a long service life;

- is distinguished by the variability of design solutions and design;

- is easy to maintain and operate;

- is lightweight;

- it is made of environmentally friendly materials;

- is moisture resistant;

- does not require large material costs;

- is subject to restoration, which increases durability.

Drawing of the garden table.

The disadvantages are:

- inflammability;

- the requirement for uniform humidity of 40-60% in the room;

- high humidity in a room that contributes to the appearance on surfaces covered with paints, stains and darkening of coatings, loss of attractiveness;

- furniture made of certain types of wood requires special care and maintenance conditions;

- undesirability of placement near working heating instrumentation.

Phased manufacturing of a piece of furniture

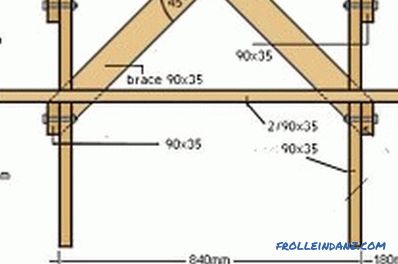

To make a table for a villa, after choosing a material, you need to create a project for a piece of furniture, make a drawing with dimensions, draw a sketch, you can use ready projects.

The project may reflect an ordinary quadrangular construction on 4 flat legs as an excellent option for eating; the table with the table top is a simple structure placed on the support legs. It becomes necessary to calculate the consumption of basic and auxiliary materials, the acquisition of the necessary equipment and tools for work. The following materials, tools and equipment may be useful in the manufacture of a piece of furniture for giving your own hands:

A plan of a garden garden table.

- board;

- cant;

- bypass strips;

- joiner's glue;

- sandpaper;

- wood screws;

- squares;

- clamps;

- screwdrivers;

- screwdrivers;

- drill bits;

- pencil;

- roulette;

- grinder;

- frezer;

- jigsaw;

- plane;

- hammer;

- chisels;

- roller;

- brushes;

- paintwork material.

In the building market, boards, bars, bypass strips are purchased, a furniture board is cut in the same place or replaced with MDF board, chipboard. We begin to make the table for the garden.

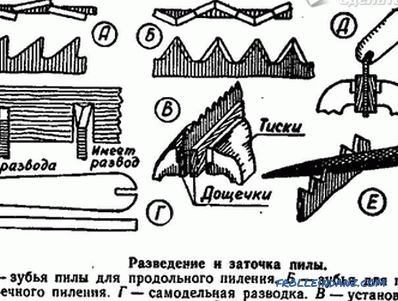

In the manufacture comply with phasing. The first step is to clean the board, designed for the tabletop by means of a grinding machine, which makes it possible to perfectly align the board, to make its surface smooth; after trimming the edges of the boards and corners. Chipboard processed edgeband. The board intended for legs also is ground.

With the help of the milling cutter, we create fitting grooves, places for the bypass bars, fix them with furniture fittings. A bypass bar is cut, it is inserted into the spacer between the support legs on all 4 sides. We make the connection with screws and fittings. The surface of the finished product can be varnished or painted with acrylic paints, pre-polished plane again; before covering with varnish and paints dirt and dust is removed from the surface.

Having made a table for giving with our own hands, we get high-quality, attractive, durable furniture that will be used for a long time.

Didn't find the answer in the article? More information on the topic:

-

Quality furniture from shields with your own hands

Furniture from the boards with their own hands. Preparatory work. Full production of a bed from the first to the last step. The time after which you can begin operation.