Bandsaws are often sold in an unused state. Professional tools must first be diluted, and then sharpened. Every two to three years, the wiring process is repeated. Incorrectly diluted and poorly ground saw can spoil all the work.

How to sharpen and dilute the saw correctly? First you need to understand the essence of these processes. Indeed, the preparation of hand tools is different from the preparation of electric. Hand saws have a completely different tooth shape and working technique.

Why bred saw

Sawing

Sawing

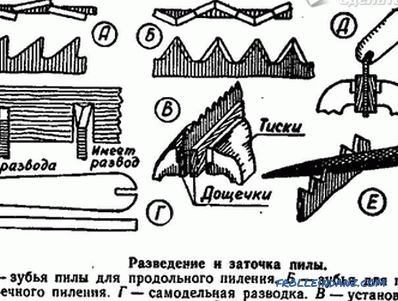

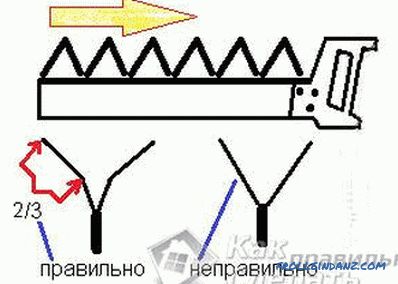

Wiring is such a process as a result of which the teeth of the band saw bend in different directions. Even teeth are bent in one direction, odd - in the other.

Before you spread the band saw, you need to understand why this is necessary. Senseless processes usually do not bring good results. It is known that during sawing the width of the cut should be twice as large as the thickness of the saw blade. If the cut is already, then the saw will start to get stuck in it. In case of improper wiring, curvature of the web is possible. As a result, the saw will go crooked, and even cut will not work.

Laying Methods

Methods One of the easiest ways to cut saw teeth is with pliers. You just need to take each clove and bend it alternately in different directions.

Methods One of the easiest ways to cut saw teeth is with pliers. You just need to take each clove and bend it alternately in different directions.

The tooth should be clamped by two thirds, then the bias will be correct.

As a result of this work, half the teeth will be bent to the right and half to the left. Another way of wiring is carried out using a special tool.

Sharpening

After breeding, the saw should be sharpened. This is done using a special set of simple tools. You can sharpen a band saw simply with the help of a regular triangular file. During sharpening, moving the file from itself, it is pressed against the teeth. Moving in the opposite direction, it must be slightly rejected.

After breeding, the saw should be sharpened. This is done using a special set of simple tools. You can sharpen a band saw simply with the help of a regular triangular file. During sharpening, moving the file from itself, it is pressed against the teeth. Moving in the opposite direction, it must be slightly rejected.

If you can sharpen a circular saw only with the help of a whole set of tools, the band saw can be brought to a working state with just a simple triangular file.

The band saw teeth should be sharpened from two peaks.

In the working process, teeth can also be eroded with a bar. When the saw is constantly sharpened, the wiring gradually disappears, the teeth are aligned. In order to return the tool to the working form, the dilution is repeated again. Overhaul and sharpening is not needed very often.

Saw care

Care It is important for the saw not only to be able to be thinned and sharpened. You must also be able to store it. When the tool is not in use, it should be placed in a warm and dry place. If moisture gets on the saw, it will rust.

Care It is important for the saw not only to be able to be thinned and sharpened. You must also be able to store it. When the tool is not in use, it should be placed in a warm and dry place. If moisture gets on the saw, it will rust.

Even when treated with special compositions, the saw will not be able to withstand all aggressive factors.

You need to take care of the tool, and then it will serve for a very long time. The saw is usually wrapped in material. You can also provide for her case. Leaving the tool for the winter on the balcony is not recommended.

Types of band saws

Two-handed saw

Two-handed saw

Band saws differ in the size of the tooth. You should also highlight:

- two-handed saws;

- single saws.

Two-handed saws are sharpened and bred in the same way as ordinary single-blades. All the difference of such a tool is that two people work with it at once.

Woods and varieties of this material are most often sawn with the help of band saws. Wood does not require too much impact, it is a soft material that is easily sawn and drilled. However, in the process, it is advisable to still fix the logs and boards. During sawing, you must be careful not to hold your hand too close to the cut furrow. This can lead to severe injuries.