In the presented material, all the stages of creating an efficient heating system for a country house with a solid fuel boiler are considered in order. Starting with the choice of equipment and power calculation, ending with installation diagrams and operating rules.

Choosing the optimal type of solid fuel boiler and equipment

At the moment there are 4 main types of solid fuel boilers.

Traditional, it is a classic

Morally inveterate structure, with extremely low efficiency - less than 60%. Requires frequent maintenance, manual loading of fuel from 4 to 8 times per day. The main advantages are low cost, high reliability and extreme simplicity.

Long-burning boilers

Their technology was developed back in the 70s of the last century and brought to its logical conclusion using modern means of temperature control. The presence of forced-flow circulation pumps makes this system a bit more efficient than the classic one, but volatile. Without going into particular features of the combustion process, we note that the fuel loading into the long-burning boiler can occur exclusively cyclically - this is uneconomical with frequent changes in temperature and is very inconvenient to maintain. In combination with a complex scheme of strapping and a whole list of restrictions during heating, this makes the operation of this device very difficult.

Pyrolysis boilers

Relatively new type. The principle of heat supply is based on the combustion of pyrolysis gas, which is released after heat treatment of the fuel. Manufacturers regulate the efficiency of such boilers for more than 90%, which is just a publicity stunt. In this calculation of efficiency, the energy that is spent on the pyrolysis process is taken into account.

Pyrolysis is the process of wood decomposition when heated without air access, which is accompanied by the release of combustible gas.

The real KDP, technically perfect, model of this type of boiler does not exceed 75-80%. And this is taking into account the ideal operating conditions, which means the moisture content of the fuel is not more than 10%. With increasing humidity, the efficiency of heat release drops rapidly. There are additional risks that arise during operation. The biggest is the potential outflow of pyrolysis gas. With the systematic loading of the apparatus with high-humidity fuel, the gas generator chamber quickly burns out. To prevent this, it is recommended to make a lining of the boiler furnace before each heating season.

Pellet type

The most technically advanced solid fuel boiler you can choose. Includes a set of control systems, process automation and security. At the moment, such equipment is the most expensive, but the most technically advanced:

- high efficiency - 85-90%;

- full automation of the pellet loading process;

- flexible temperature management system in rooms;

- high degree of safety during operation.

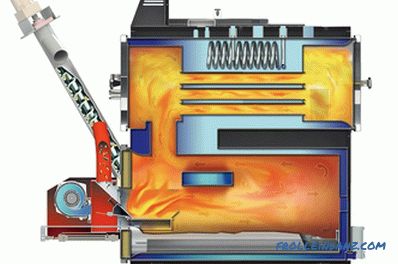

Device and technical characteristics of the pellet boiler:

1. Pellet bunker;

2. Auger for feeding pellets;

3. Electric auger;

4. Nozzle for supplying fuel to the burner;

5. Dispenser that supplies fuel to the burner;

6. Electric ash cleaner;

7. Heat exchanger - triple passage of high-temperature gases gives high efficiency;

8. Control Panel;

9. Control windows for the presence of fuel pellets in the bunker.

Schematic principle of operation of a pellet heating boiler.

Fuel pellets, which are used as fuel in these boilers.

In turn, pellet boilers can be divided into three types, according to the type of structure of the main element of the combustion chamber.

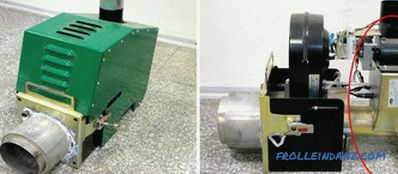

Flare burner

This is the least economical technology used in this type of equipment. Combustion of fuel occurs in the air flow created by the fan, at temperatures up to 1200 0 C. A distinctive feature of this technology is versatility and unpretentiousness to the quality of fuel.

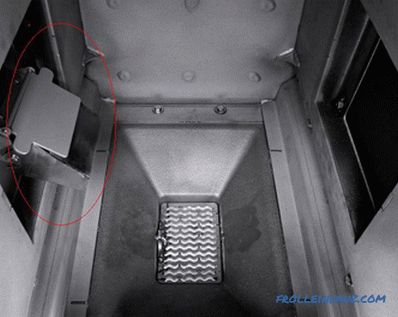

When choosing this type of burner, make sure that there is an additional dispenser chamber (highlighted in the figure) with a locking shut-off valve that prevents back burning. This will make the pellet feeding process more economical and safe.

The grate

With this method, pellets are fed into the storage hopper, and then dumped under their own weight onto the grate. At the bottom of the air is blown to support combustion. Grate bars can be fixed and mobile. The latter are used to burn fuel of large fractions with high ash content.

The combustion chamber, the pellet supply valve is highlighted.

The grate, which is also built into the conical pallet.

Retort burners

A steel or cast-iron bowl on which combustion takes place. Pellets are fed along the chute from below with a special feed screw. Primary combustion air is supplied in the same way. Secondary air to control and intensify the process is fed through the openings in the retort.

Video: Supply of pellets in the retort burner

Additional equipment for the boiler

Almost all modern models have the following functionality as standard:

1. Automatic ignition - optimal use of a high-temperature hair dryer in a thermally protected fail-safe housing. Metal or ceramic heating elements are also used, but they are less durable. The electrode method is very sensitive to the moisture content of the granules.

2. System Monitoring . Basically, various types of thermostats are used to control the temperature of the coolant and lambda probes, which determine the amount of residual oxygen in the flue gases. Both detectors control the power of the fan forcing air into the furnace.

Choosing the most efficient model

Before choosing a solid fuel boiler, it is necessary to determine its capacity and the technical criteria it must meet, namely:

# one. Availability of a certificate of adaptation of all boiler components for operation in the territory of the Russian Federation.

# 2. The presence of several modes of robots with different types of pellets.

# 3. Ability to use another type of fuel.

# 4. Level of fuel quality requirements;

# 5. The presence of hot water supply and the possibility of including an economical "summer" mode of operation;

# 6. Reliability of long-term uninterrupted work;

# 7. The level of reproducible noise in various operating modes:

- standard heating;

- increased heating with DHW;

- starting ignition;

- feed fuel pellets from the inner and outer bunker;

# 8. Ability to connect external additional control;

# 9. Scaling of temperature control of the premises;

# 10. Access and size of ash bin;

# 11. Availability of safety systems

- control of reverse thrust;

- control of coolant overheating;

- automatic emergency shutdown and fire extinguishing system.

Rules for installation and arrangement of the boiler room

For convenient operation, installation of a pellet solid fuel boiler must be carried out in a spacious room. When placing it, it is necessary to observe the parameters of technological spaces from walls and other surfaces that are indicated in the passport of the product.

In practice, there were cases when, after six months of operation, it was found that it was impossible to open the ash pan to clean it.

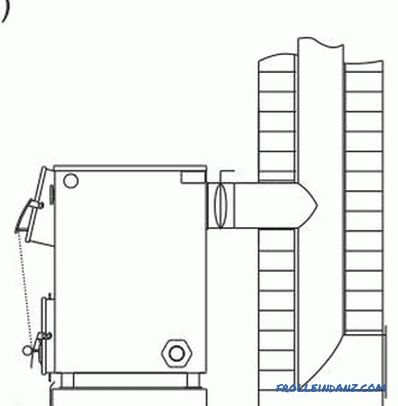

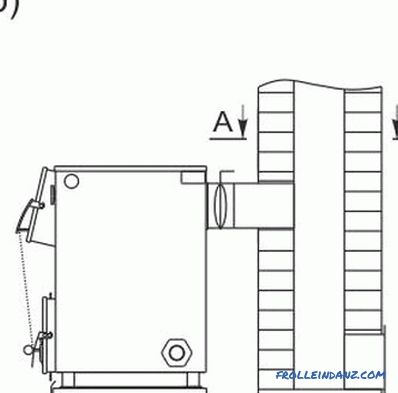

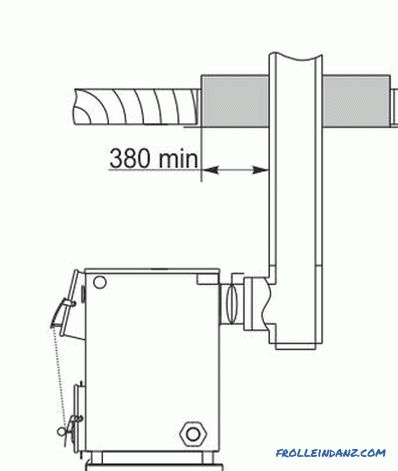

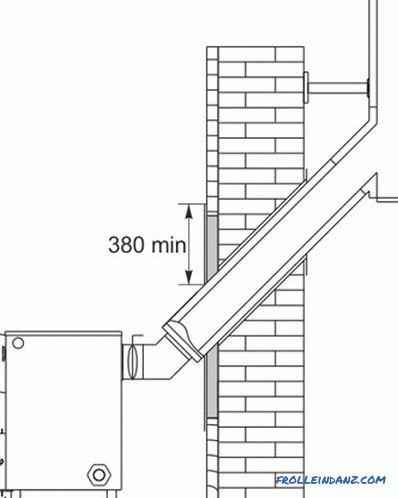

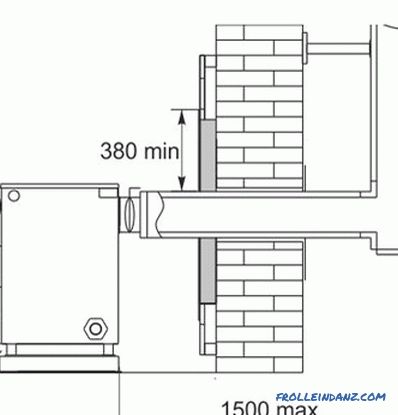

The main criterion for the suitability of a room is good natural or forced ventilation and a properly arranged chimney. The most commonly used scheme of the chimney device, you can see below:

Diagram A and B indoor chimney device houses. As an exhaust duct, ventilation shafts, arranged in the thinnest of walls, are used. These channels must be isolated from the main system of natural ventilation of the house.

Scheme B - removal of the chimney from the boiler room located in the basement.

Schemes D and D construction of an external chimney from a specially constructed boiler room or a house.

In all the chimney device options, you must install:

- a spark arrester on the flue pipe;

- sealing the transition sleeve in boiler room;

- drainage device.

Installation of a solid fuel boiler is recommended to be carried out on a foundation pad with a heat insulating layer. Indoors, it is necessary to install a special gas analyzer if this is not in the standard equipment of the model purchased

Rules for the installation of a pellet bunker

In addition to the built-in bunker, which has a small volume and must often be filled with fuel, many owners connect a large external hopper to the system.

Any containers will be suitable for storing pellets, the main condition is the tightness of the structure, if it is outside the heated room. Choosing the volume of the bunker, it is necessary to proceed from the standard 1 ton of pellets takes up to 2 m3. the height of the structure is not critical.

It is believed that in high containers the lower layers of granules are crushed, this is not true. Qualitatively made fuel pellets withstand quite a lot of pressure.

The tank should be at a distance of no more than 12m from the boiler. A complication of the screw design or the use of transfer hoppers for storage tanks is allowed, but only high-quality fuel is needed. Otherwise, trash that enters the furnace in large quantities will reduce efficiency and may damage the supply and dosing mechanisms of the boiler.

In the lower part of the bunker cone, under the exit of the fuel intake, it is necessary to provide for an audit to systematically remove the rot. If the cone has a small cross-sectional area, a mass of granules compacted under pressure hangs. In this case, it is recommended to install a special tool "screw agitator".

Bunker connected to the boiler.

Using the heat accumulator and calculating its volume for a solid fuel boiler

When using powerful heating devices, there is a possibility of overheating of the heat carrier. And although modern models have perfect automatics, which prevent such situations, it is advisable to use special heat accumulators.

Heat accumulators perform the following functions:

- automatic control of the distribution of the heated coolant through the system;

- using the exchanger as a buffer when creating hybrid heating systems with several types of heaters;

- some models can perform the function of a DHW boiler; increase boiler efficiency by reducing the number of thrust adjustments.

Calculation table of heat storage volume for solid fuel boiler

| Heat storage volume (l) | Water heating time (H) at the boiler power (kW) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 20 | 25 | 30 | 35 | 40 | 15 | 50 | 55 | 60 | |

| 500 | 1, 2 | 0.9 | 0.8 | 0.7 | 0.6 | 0.5 | 0.5 | 0.4 | 0.4 |

| 1000 | 2.3 | 1.9 | 1.6 | 1.3 | 1.2 | 1.0 | 0.9 | 0.8 | 0.8 |

| 1200 | 2.8 | 2.2 | 1.9 | 1.6 | 1.4 | 1.2 | 1.1 | 1 , 1 | 0.9 |

| 1500 | 3.5 | 2.8 | 2, 3 | 2.0 | 1.7 | 1 , 6 | 1.4 | 1.3 | 1.2 |

| 1800 | 4, 2 | 3.4 | 2.8 | 2.4 | 2.1 | 1.9 | 1.7 | 1.5 | 1.4 |

| 2000 | 4.7 | 3.7 | 3.1 | 2.7 | 2.3 | 2.1 | 1.9 | 1.7 | 1.6 |

| 2400 | 5.6 | 4.5 | 3.7 | 3.2 | 2.8 | 2.5 | 2.2 | 2 , 0 | 1.9 |

| 3000 | 7.0 | 5.6 | 4, 7 | 4.0 | 3.5 | 3.1 | 2.8 | 2.5 | 2.3 |

| 3500 | 8.1 | 6.5 | 5.4 | 4.7 | 4.1 | 3.6 | 3.3 | 3.0 | 2.7 |

| 4000 | 9.3 | 7.4 | 6.2 | 5.3 | 4.7 | 4.1 | 3.7 | 3.4 | 3.1 |

| 4500 | 10.5 | 8.4 | 7.0 | 6.0 | 5.2 | 4.7 | 4.2 | 3.8 | 3.5 |

| Green shows the optimal volumes for the respective boiler capacities. |

Different types and schemes of tying solid fuel boiler

There are many ways to connect the boiler and related equipment to the general heating system of a house. Consider the most common ones.

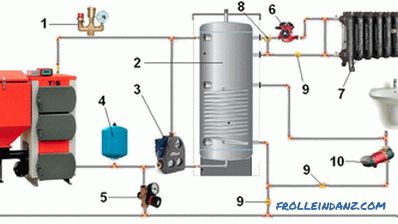

The storage capacity performs the function of a DHW boiler.

The design of the storage capacity is a spiral inside the heat accumulator. The hot coolant that is inside heats the running water of the hot water circuit. In the case of burning and shutting down the boiler, the heat accumulator allows to maintain an acceptable temperature in the room, up to 2 days. Provided that the dhw function is not used.

The automatic thermo-mixing device is used to control the coolant flow and temperature:

- Ball valve;

- Thermometer;

- Pump.

The device is also equipped with a non-return valve, an emergency automatic valve for natural circulation (in case of a power outage), an integrated thermo valve and a choke.

The principle of the device is as follows. When the coolant reaches a certain temperature (780C), the thermal vent opens the water supply from the storage tank.The temperature is kept at a given level by regulating the cross section of the return passage from the central heating system to the bypass channel.

Connection diagram of a solid fuel boiler to a dual purpose heat accumulator:

1. Security group;

2. Thermoaccumulative tank;

3. Thermomixer;

4. Expansion tank membrane type;

5. System make-up valve;

6. Heating circulation pump;

7. Radiators;

8. Three-way mixing valve;

9. Check valve;

10. DHW circulation pump.

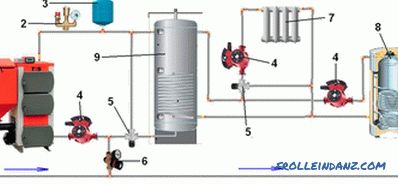

Connection of the heat accumulator and separate DHW boiler

The volume of the boiler for passive heating of the DHW system depends on the number of consumers and the capacity of the equipment used. When tying pellet boilers it is not recommended to use polypropylene materials and structures. The temperature of the heat exchanger at the outlet at peak loads often exceeds the performance of pipes made of polymeric materials.

Binding of a solid fuel boiler with a separate DHW boiler:

1. Boiler.

2. Security group.

3. Expansion membrane tank.

4. Circulating pump.

5. Manual three-way mixing valve.

6. System make-up valve.

7. Radiator.

8. DHW boiler indirect heating.

9. Thermoaccumulative tank.

Parallel connection of two boilers

In order to extend the life and evenly distribute the resources used, users often combine two different types of heating sources into a single heat supply scheme. In this case, the main source of heat in the winter period is a solid fuel boiler. The electric boiler is switched on in emergency mode and in the summer months when used to heat water.

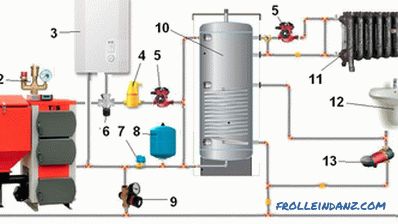

Piping scheme for a solid fuel heating boiler with parallel electrical connection:

1. Pellet boiler.

2. Heating system security group.

3. Alternative boiler (electric or gas).

4. Separator to remove air from the system.

5. Circulating pump.

6. Manual three-way mixing valve.

7. Dry run protection valve.

8. Expansion tank.

9. Water make-up valve.

10. Thermoaccumulative tank.

11. Radiator.

12. Washbasin.

13. DHW circulation pump.

A heating system based on a pellet boiler is quite complex and requires careful adjustment. Before carrying out installation work, thoroughly familiarize yourself with the guidance material provided by the manufacturers.