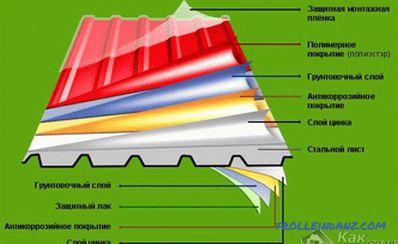

Profiled sheeting and steel (tin) sheet are very similar in structure, but the methods for cutting them are different. Unlike tin sheet, this material is subjected to profiling (to enhance rigidity) and has a corrosion-resistant polymer coating. When self-cutting, be sure to follow the rules, trying to minimize damage to the protective coating. In this article we will explain how and what to cut the material, as well as give an explanatory video.

Material features

What is profiled

What is profiled

When choosing a tool For sawing, an important factor should always be taken into account: the protective coating does not withstand high temperatures. Therefore, in this case, always give preference to the cold method of cutting for metal and correctly select the required tool.

Cutting corrugated flooring using autogen, plasma and other similar tools is categorically not suitable for cutting this material. Abrasive tools (for example, Bulgarian) also belong to the list of unsuitable tools because they cause charring of the anti-corrosion coating, heating of the metal and burning out of zinc. We suggest to look into the better way to cut material for the fence in order to ensure its safety as much as possible.

Tool selection

First, we list the recommended tool.

Hacksaw for metal

Hacksaw for metal

Conventional hacksaw for metal . It is considered the safest tool. The process is manual, but it takes not so much time as it seems at first glance, since the professional flooring is cut out with a hacksaw rather easily. With this method, there is no high temperature, and the sheet is well preserved.  Scissors for metal The disadvantages include: the inability to cut complex shapes and the need for a special desktop.

Scissors for metal The disadvantages include: the inability to cut complex shapes and the need for a special desktop.

Jigsaw (electric or manual) . Great for separating various curvilinear complex shapes. In the case of jigsaw, this process is accelerated and simplified.

Scissors for cutting metal (manual or electric) . This tool, unfortunately, is not so widespread, but I want to note that it is easy to use - metal sheets are cut by them rather quickly and easily.

There is one drawback - the edge may turn out to be not perfectly smooth, but this is not terrible, because when laying it can be closed with the following sheet.

Bulgarian for cutting professional flooring

Bulgarian for cutting professional flooring

Bulgarian. On the grinder, the abrasive disc must be replaced with a special disc. Thanks to the material from which this special disc is made and its shape, sawing is more accurate and delicate. Such discs are made of an alloy of high-strength metals, so the teeth of the discs do not break during the process of cutting hard metal sheets.

In any case, the tool should be made of carbide metal.

Cutting

Tool for cutting professional flooring

Tool for cutting professional flooring

When using any of the above tools, when performing cutting, pay attention to minimize the area of violation of the integrity of the coating. After all, no matter how carefully you cut, the integrity of the protective coating on the end part will still be broken, and this will affect the life of the corrugated board.

Staining of profiled

Staining of profiled

You will hardly be able to restore the protective coating completely, but you can process Anticorrosion drug cutting place, and then paint over them for greater reliability. Use factory paint, which is usually attached to the material. If the paint was not included in the kit, then it does not matter - purchase a can in the hardware store that matches the color and texture of the paint. Having processed, thus, a professional flooring, you protect places of seams from adverse effects of the weather phenomena.

Video

In the following video you will see how easily the grinder can be used: