Metal tile is an easy-to-use material that you can install yourself. Some beginners believe that working with metal tiles is available only to highly qualified professionals. In fact, there is nothing difficult in the installation. It is only necessary to understand some of the details on working with this material. In this article, we will describe how to make a roof of a metal tile with your own hands, give step-by-step instructions for installing the roof of a roof, and also give you visual photos and video materials.

Types of coatings

Types of metal tile

Types of metal tile

Types of roofs for a bath Before roofing a metal tile, it is necessary to understand the varieties of this material. The main differences are contained in the coating plates.

Types of roofs for a bath Before roofing a metal tile, it is necessary to understand the varieties of this material. The main differences are contained in the coating plates.

- Plastisol coating. This metal is very resistant to all types of influences. She serves a very long time. True, metal coated with plastisol, is quite expensive. It is much more expensive than other varieties of material. But the roof will be very durable and will not flow.

- Matte polyester coating. The most accessible type of metal tile. This material is resistant to moisture and frost. You can make such a roof, even with a modest budget.

- Polyester coating is another type of tile. A good choice for roofing. Such metal tile combines quality and low cost.

A significant difference between the materials is the nature of the locks on the plates. Fasteners can be open or hidden. In addition, the castle itself often has various forms. Profile sizes are different, respectively, and different pitch when mounting plates. All this suggests that before buying it is necessary to take measurements and select the desired material.

Roof covering

When the material is purchased, you can begin to cover the roof. The roof of the metal is stacked in several stages.

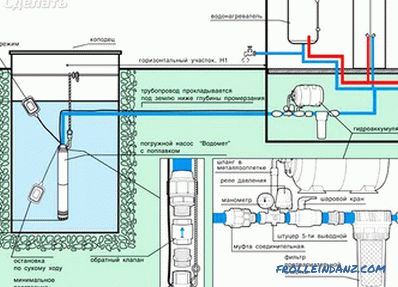

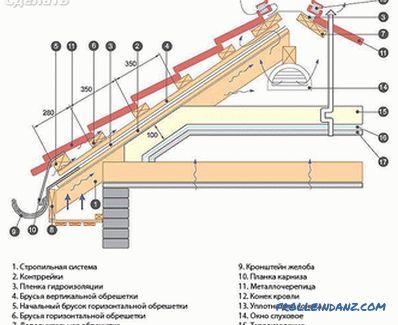

- The first stage is the installation of waterproofing. Usually it is done according to the standard scheme. On the waterproofing layer is attached crate, which will become the basis for the installation of metal. When installing waterproofing, you should not forget to leave the slack, otherwise it will work poorly.

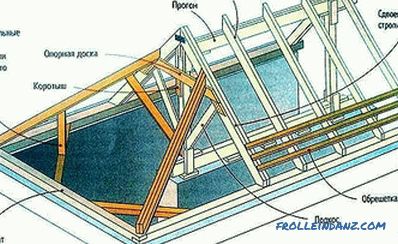

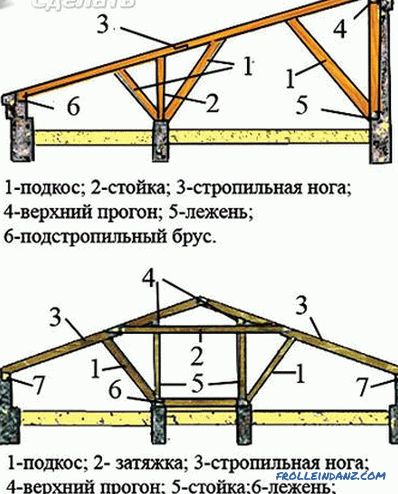

- Mounting the batten is a fairly simple step. We must take the bars and nailed to the roof frame. Bars need to be treated before installing a special antiseptic composition, otherwise they may collapse. Instead of wood, you can use a perforated profile.

-

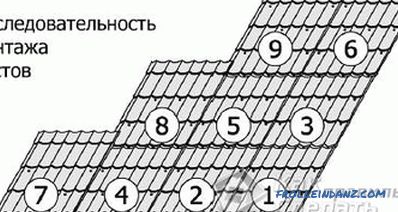

Sequence for mounting sheets When laying metal tile, observe one rule. Regardless of the type of roof material is placed from the highest point to the lowest. If the roof is shed, then you need to start work from its top. If the roof is duo-pitch, it is necessary to choose the left or right part and lay the metal tile first on one half (from the ridge down), and then on the other.

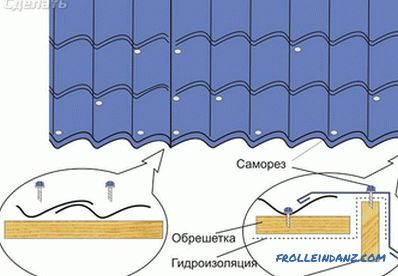

Sequence for mounting sheets When laying metal tile, observe one rule. Regardless of the type of roof material is placed from the highest point to the lowest. If the roof is shed, then you need to start work from its top. If the roof is duo-pitch, it is necessary to choose the left or right part and lay the metal tile first on one half (from the ridge down), and then on the other. - When laying metal tile, each next layer should be put under the top one. Self-roofing of the roof with a metal tile begins with fixing several tiles on the very top with galvanized self-tapping screws.

- Between themselves, the horizontal row of tile is also overlapped.

- To cover the ridge of the roof it is necessary to use special elements of metal tile.

Any crate is put on the waterproofing through the counter rail. This device will allow the roof to "breathe."

There is nothing difficult in this work. It is only necessary to lay out the first row and align it, and then the process will go easy. The roof of the metal is very aesthetic and will delight its owner for many years. To understand how to lay the material correctly, you need to find out the structure of the roof of the metal tile.

Device

Work with metal tile

Work with metal tile

Metal roof tile is difficult to confuse with any other . It has its own characteristic pattern. Before you start working with the material, you need to make a drawing and determine the required amount of metal tile.

If you look at the metal tile roof, you will notice that it has “waves” and rows. Professionals have a special concept associated with this material. It is called "metal tile pitch" and represents the distance between two rows. Six steps of such a roof of 35 cm each constitute a module. Metal tile is measured by modules.

However, the master can order his own set of metal tiles. It will be a little more expensive than buying a complete set, however, this approach will pay off in that the waste will be significantly less. When ordering it should be remembered that the metal has dimensional limits. For example, it can not be longer than 45 cm.

Calculation

The calculation of the roof of metal should be carried out very carefully.

- To calculate the required amount of material, you must first make a roof drawing. Of course, the roof must first be measured.

- Then, you should take the dimensions of the metal-tiled sheets and lay them on the roof surface in the drawing.

- In calculations it is important to remember that the sheets also overlap each other.

The metal tile is cut if necessary. But this is not a reason to take the first set of modules.

Details

Installation

Installation

Ladder to the roof The metal tile does not fit any roof. The roof must necessarily have a slope of at least 11 degrees.

Ladder to the roof The metal tile does not fit any roof. The roof must necessarily have a slope of at least 11 degrees.

It is important to remember that for self-tapping screws when installing metal tiles, it is necessary to make rubber linings. This is a technological requirement.

Metal tiles require special handling. Work with it begins with the display of material from the package. This must be done with gloves on. It is generally better to work with a metal tile in gloves. Raising sheets to the roof is carried out with the help of a special system of guide boards.

Mounting tools

Fixing

Fixing

To work, the wizard will need a number of tools which is best prepared in advance. These are:

- screwdriver;

- ruler or rail;

- hammer;

- tool for cutting metal tiles.

Cutting metal tiles

Cutting metal tiles

You will need to cut:

- metal shears;

- circular saw;

- jigsaw;

- cut-up shears;

- hacksaw.

Tools with abrasives should not be used when cutting material.

We must be very careful about the sawdust that remains on the metal tile after cutting. They need to be removed.

Difficult moments

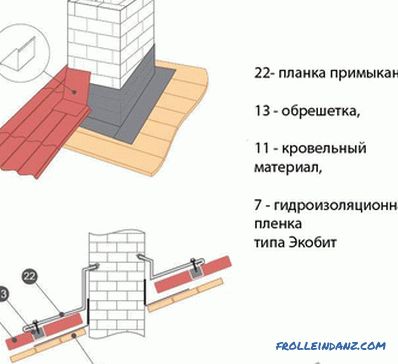

Arrangement of a chimney

Arrangement of a chimney

It will be more difficult to make a roof of metal tile if the house has attic windows. When installing the roof will have to cut pieces of metal or order the material of a certain size. Usually the size of such windows is 10 times smaller than the area of the roof itself.

Roof railing

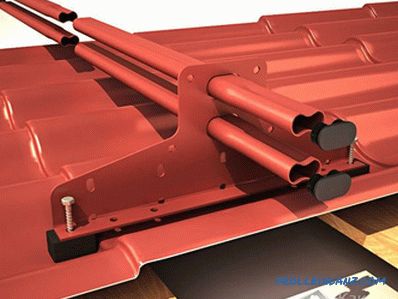

Roof railing is installed for safety. It is mounted in the lower points of the "wave" metal-tiled coating. Installation is done strictly with galvanized screws through the rubber lining. First mounted support, and then the fence.

Roof railing is installed for safety. It is mounted in the lower points of the "wave" metal-tiled coating. Installation is done strictly with galvanized screws through the rubber lining. First mounted support, and then the fence.

Ladder

The ladder is also mounted on brackets. They are mounted in the deflection of the wave metal. Then the design itself is attached to the brackets. When installing brackets on the wall, no gaskets are required, but when installing to the metal tile, it is necessary to make a rubberized base.

Snow harnesses

Snow harnesses on the roof

Snow harnesses on the roof

Snow harnesses prevent snow from falling as snow falls the roofs. Installation should begin in the place where the continuous crate is located. This place should be removed from the edge of the roof by 35 - 40 cm. By the way, such structures should be installed above the roof windows.

In addition to snow holders and ladders, installation of various ventilation elements, transition bridges and other things may also be required on the roof. Such work is done simply, the main thing is to follow the instructions for installing additional elements on the metal tile.

If it is necessary to make a hole for ventilation, the edges of the tile after cutting should be treated with a sealant.

Grounding

Grounding of the roof

Grounding of the roof

Skylights Metal tile requires mandatory grounding. It can be of three types:

Skylights Metal tile requires mandatory grounding. It can be of three types:

- cable;

- rod;

- net.

The choice of the type of ground depends on how generally the threat of a lightning strike is real in a particular case. Grounding in this case is mandatory, but in one case it is possible to get along with a simpler device, while in the other you will need a complex structure.

Usually for installation of any type of grounding attract experts. But if you wish, you can do it yourself.

Any grounding consists of the following elements:

- grounding circuits;

- tokododes;

- interception rods;

- outlets.

When struck, the lightning strikes the interception rod, then it dissipates when it enters the circuit. It is easy to install the contour, only a number of earthworks will be required. If you have free time, you can do everything yourself.

Video

We also recommend that you familiarize yourself with the following video about the installation of a metal tile:

You can find additional video in our video section: Video about installation of a metal tile.