The electric jigsaw is essentially a universal tool that allows you to perform straight and curved cuts of a wide variety of materials - from soft wood to steel and glass. However, the tool itself is universal, but not its equipment: each task requires a certain type of saw blade. To understand how to choose a saw for an electric jigsaw in each specific case, you need to figure out what criteria to use when choosing what some of the blades are different from others and how to guess about them by marking them.

When you go to the store and look at the jigsaw stand, you will find that they are all very different. They differ not only in the length, width and thickness of the blade, but also in the size of the teeth, the geometry of the cutting edge and the appearance of the tail section. In this material, we consider what types of jigsaws for jigsaw there are, their features and selection parameters.

Types of shank files for electric jigsaw

The first thing you should pay attention to when choosing a file for electric jigsaw is its type of shank. And this is logical: if your tool is not designed to work with this kind, then you simply can not use the new canvas. In fact, there are not so many options:

T-shaped shank .

Often it is called "Boshevsky", because it is this company that has developed files with this type of shank. Since BOSCH is the market leader in electric jigsaws and accessories for them, and other industry giants are trying to move to this standard, it is not surprising that T-shank files are the most common at the moment. T-shank is suitable for most modern jigsaws - Bosch, Makita, Metabo, Hitachi, Skil, AEG, DeWalt, Sparky, Interskol, etc.

U-shaped shank .

The second most popular type of shank, the American standard. This is a universal shank for old models of electric jigsaws Skil, DeWalt, Wolf, Ryobi, Stayer, Black. Decker and others. Such files are suitable for all jigsaws with shoe and screw clamps.

Makita Shank .

Files with this shank are compatible only with older models of Makita jigsaws.

Bosch Shank .

It differs from a T-shaped shank only by the presence of a second stop. Such files are suitable only for old Bosch models.

The last two types of shanks can already be attributed to the category of rare books. To find such files in domestic stores today is almost impossible.

File sizes

Blade length . The length of the saw blade can vary in a fairly wide range - from 40 to 250 mm. The longer the file, the thicker the workpiece it is able to cut. It should be borne in mind that the really achievable cutting depth depends not only on the length of the blade, but also on the capabilities of the tool itself. For sawing thin materials, it is better to use short files: using them guarantees a neat, clean cut, since the process is not hindered by the deformation of an excessively long blade.

Canvas width . The width of the canvas is selected depending on the type of operations that are supposed to be performed using the jigsaw. For straight cuts, wide files are ideal: they are easier to drive in a given direction, which means the cutting line is smooth.

For figure cuts, on the contrary, it is necessary to have a canvas with a narrow back, which makes it easier to perform various maneuvers, “drawing out” smooth curves.

Web thickness . And, finally, the thicker the file is, the less it will deviate from the vertical position during the work, i.e. the cut will be perpendicular to the material surface. However, in the pursuit of a neat cut, do not forget that too thick files may not be suitable for jigsaws with quick-release mechanism.

The types of files in the cutting edge geometry

If you look closely at the file for jigsaws, you will notice that they all differ in the size of the wiring of the teeth and the geometry of the cutting edge. The stronger the teeth are divorced, the wider the cutting line will be, thereby increasing the speed of work, however, at the cost of cutting down the quality. Not only the cleanliness of the kerf, but also the fact that you can use this tool to work with which materials depends on the wiring method.

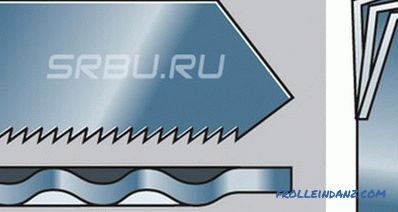

Milled with classic wiring.

Features . In classic files, the teeth are alternately bent in different directions, like in ordinary hand-saws. Such a layout helps to reduce the heating of the file in the process of work, since the web almost does not experience friction in a fairly wide kerf. It is almost impossible to get a neat cut with such a file, but the speed of work will be high.

Assignment . The purpose of saw blades with milled teeth and classical wiring is a quick cut of hard and soft wood, as well as plastic and non-ferrous metals.

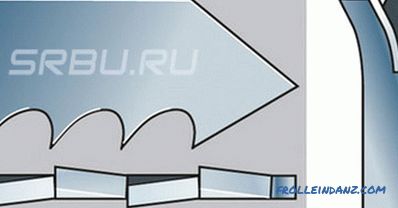

Milled with wavy wiring.

Features . In a tooling with such a wiring, the teeth do not change direction in turn, as in the previous case, but in groups of several. In this case, for each tooth, the deviation from the central axis is not the same as that of its nearest neighbors - the working edge of the saw blade forms a wave.

Assignment . The purpose of the wavy files is a clean cut not only for wood, but also for chipboard or plywood, as well as working with non-ferrous metals and plastic.

Polished with classical wiring.

Features . The teeth of such cloths are set apart and undergo a grinding process. The cutting line of such canvases is quite wide.

Assignment . Files with ground teeth, diluted in the classical way, are designed for fast but relatively clean cutting of wood and its derivatives - chipboard, fiberboard, etc.

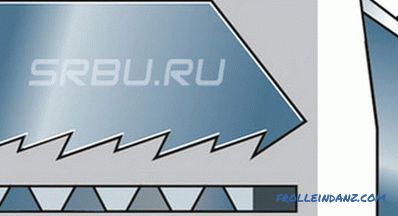

C conical grinding without wiring.

Features . The blades of such files do not have a tooth divorce, but their segments are ground, which ensures a thin cutting line and an even cut.

Assignment . Allow to carry out accurate cut of wood, a laminate, polymeric materials.

Classification of jigsaws for jigsaws by type of processed material

For wood and wood materials

Initially, the jigsaw was created to work exclusively with wood. Modern tools have learned to cut both metal and plastic, but their main purpose is still cutting wood and its derivatives. That is why most of the range of saw blades is designed to work with these materials. "Wooden" files are divided into groups according to the type of work for which they are intended.

Fast cut .

When carrying out certain types of work with wood, it is often not the accuracy that is important, but the speed of the process. Provide high performance work capable of sawing for fast cutting of wood. They are easy to recognize by the following characteristic features:

- long blade (from 60 mm),

- large teeth (up to 6 mm),

- large divorce ( about 1 mm).

Tip: Fabrics with a straight tooth are also suitable for cutting wood across fibers, and oblique files are more suitable for longitudinal cuts.

Clean cut .

Operations such as cutting furniture panels made of chipboard or cutting floorboard require a smooth and neat cut. When solving such problems, where the quality of work, rather than productivity, comes to the fore, we use blades for a clean cut, having:

- average tooth size (not more than 3 mm),

- minor divorce.

In most files, the teeth are directed toward the jigsaw. To the front side of the material after cutting chipboard or laminate turned out as neat as possible, without chipping and scoring, the workpiece is placed with the back side to itself / the tool. To cut from the "face", you need to use a canvas with a reverse tooth. However, it is more difficult to work like this than usual - you have to overcome the force of pushing out the tool.

Tip: Carefully, without chipping, a special file with two rows of teeth allows cutting off laminated on both sides of the panel.

Figured cut .

It is almost impossible to cut a curve with a small radius using an ordinary wide web. For figure cutting, specialized saws are used, which due to their size easily pass rounded sections:

- narrow blade (no more than 4 mm),

- small teeth (up to 2 mm),

- short length (up to 40 mm),

- beveled back side.

For metal

I must admit that the jigsaw is not very suitable for cutting metal: the tool can hardly cope with the load, the process is very slow, sawing dull quickly. However, sometimes this extreme method is justified.

Metal saws differ from wood files: they are made of extremely durable steel and have small (up to 1 mm) teeth, which are diluted in a wave-like manner. If you often use electric jigsaw and at the same time perform a wide variety of works with it, we recommend keeping three blades for metal on hand - separately for aluminum, other non-ferrous metals and steel. If you have to cut the metal only occasionally, it will be enough to have only a file for steel - it will certainly cope with the cut of products made from non-ferrous metal.

For polymeric materials

For cutting pipes and other PVC products, large teeth can be used for cutting wood or metal.

The fine-toothed files also cope with the task, but the sawing will have to be at minimum speed, otherwise plastic sawdust softened by the high temperature will clog the teeth of the file. For thin sheets of plastics and plexiglas, fine metal teeth canvases are excellent. To cut thick plastic, you can take a file on the tree and cut it at low speed.

For specific tasks

Files intended for glass and ceramics are made of highly durable alloys and have diamond spraying on their cutting edge or more often carbide sputtering tungsten. Use jigsaw for cutting ceramic tiles or glass makes sense only if you need to cut curly elements; For a direct cut of these materials there are other, more suitable tools.

Drywall and other building materials containing abrasive particles of gypsum, cement or sand will quickly blunt any files. The exception is made specifically for these materials saw blades with carbide tipped on the cutting edge.

A file intended for cutting cardboard, rubber and other soft materials is more like a knife. It is "toothless", and its cutting edge is made in the form of ground waves.

Universal

Universal saws, made, as a rule, from high-speed steel, are used to work with various materials - wood, plastic, metal. Expect a high quality cut when using them is not worth it.

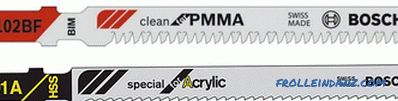

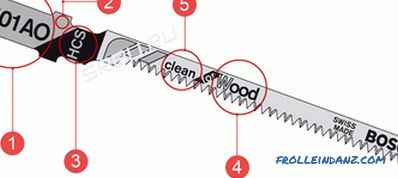

How to decipher the marking of the file

Determining the purpose of the file solely by its appearance is not an easy task, it requires experience. For those who do not have such experience, we recommend focusing primarily on the marking on the canvas, which contains all the necessary information. There is no single standard for marking files, but most manufacturers try to adhere to the classification from Bosch.

# 1. At the tail of each file there is a set of numbers and letters.

The first letter indicates the type of shank, for example, T-shaped or U-shaped. It is followed by a number, by the size of which one can judge the length of the canvas:

- 1 - short (up to 75 mm),

- 2 - standard (75-90 mm),

- 3 - elongated (90-150 mm),

- 7 - long (more than 150 mm).

In the second and third digits, the purpose of the file is encrypted. We will not deal with decoding, since this information is duplicated on files in other, more accessible for understanding and memorizing forms.

After the numbers, the letter is again - it indicates the size of the teeth:

- A - small (for cutting laminate),

- B - medium (for sawing wood, plywood, fiberboard, chipboard, etc.),

- C and D - large (for rough cut).

And finally, the last letter will help to get additional information about the file:

- F - bimetallic cloth (considered the strongest and most durable),

- О - a narrow blade (for a shaped cut),

- P - a thick blade (allows you to cut strictly perpendicular to the surface),

- R - with a reverse tooth,

- X - with variable tooth size (universal blade suitable for cutting any materials).

# 2. The purpose of the file can be identified by the color of the shank:

- gray for wood,

- blue for metal,

- white for wood and metal,

- red - for plastic,

- black - other materials.

# 3. The purpose of the saw blade is determined primarily by the steel grade from which it is made. The letter designation of the steel grade can be found on the neck of the file, i.e., on the border of the shank and the blade itself:

- CV - vanadium steel (for wood and wood boards),

- high carbon steel (for wood and wood plates, as well as plastic),

- HSS - high-speed steel (for ferrous and non-ferrous metals),

- HM - hard alloy based on tungsten carbide (for ceramics, fiberglass, etc.)

BM (or BIM, or Bi-Metal) is a highly elastic combination of HSS and HCS (professional files for wood and metal).

# 4. The purpose of the saw file is indicated by the marks on the canvas itself:

- Wood - for soft wood and fiber boards,

- Hardwood - for hard wood and laminated panels,

- Inox - for stainless steel,

- Alu - for aluminum,

- Metal - for tin, metal profiles and pipes,

- Fiber. Plaster - for fiberglass,

- Soft material - for soft materials (rubber, foam, cardboard, etc.),

- Acrylic - for polycarbonate and plexiglass.

# 5. Sometimes there is an inscription on the canvas specifying the type of work:

- basic - standard blades for high-quality cuts,

- speed - files for quick cuts,

- clean - blades for clean cuts (without toothing),

- progressor - versatile files with variable tooth size,

- flexible - ribbed fabrics for cutting metal,

- special - files for cutting ceramics, plastics and other highly specialized works.